ord Cargo classic truc

Page 31

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

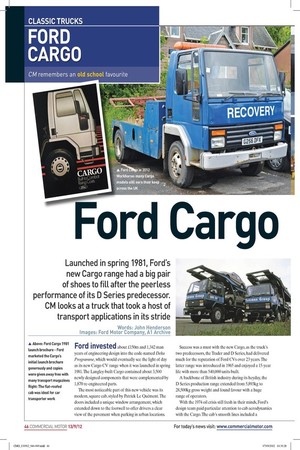

Launched in spring 1981, Ford’s new Cargo range had a big pair of shoes to fill after the peerless performance of its D Series predecessor. CM looks at a truck that took a host of transport applications in its stride

Words: John Henderson Images: Ford Motor Company, A1 Archive Ford invested about £150m and 1,342 man years of engineering design into the code-named Delta Programme, which would eventually see the light of day as its new Cargo CV range when it was launched in spring 1981. The Langley-built Cargo contained about 3,500 newly designed components that were complemented by 1,870 re-engineered parts.

The most noticeable part of this new vehicle was its modern, square cab, styled by Patrick Le Quément. The doors included a unique window arrangement, which extended down to the footwell to offer drivers a clear view of the pavement when parking in urban locations. Success was a must with the new Cargo, as the truck’s two predecessors, the Trader and D Series, had delivered much for the reputation of Ford CVs over 23 years. The latter range was introduced in 1965 and enjoyed a 15-year life with more than 540,000 units built.

A backbone of British industry during its heyday, the D Series production range extended from 5,893kg to 28,500kg gross weight and found favour with a huge range of operators.

With the 1974 oil crisis still fresh in their minds, Ford’s design team paid particular attention to cab aerodynamics with the Cargo. The cab’s smooth lines included a three-plane front panel and a unique air collar built into the rear perimeter edges. The original launch brochure claimed that optional components such as a roof spoiler and under bumper air dam would improve fuel economy by 25% and 10% respectively. Visibility from the Cargo’s driver’s seat, trimmed in black with some red striping, was excellent. Ford proudly declared a windscreen more than a third larger than the D Series, which was complemented by 75% more glazing on the sides. The Cargo’s fourand six-cylinder Dorset engine line-ups were carried over straight from the D Series range and similarly mounted at 45 degrees to the vertical. This arrangement helped keep the internal cab loor height to a minimum. A choice of two V8 engines from either Cummins or Perkins were also offered at the Cargo’s launch.

A cornucopia of specifications

On the transmission front, Ford supplied four-, sixand eight-speed gearboxes that were complemented by an optional ZF ive-speed unit on models up to 14.7 tonnes. Unsurprisingly the reliable D series rear-axle ensemble was used to good effect. Initially, the Cargo came in either fouror six-wheeled rigid formats, which were complemented by a 4x2 tractor unit. A veritable cornucopia of preliminary speciications on offer catered for GVW operations between 6 and 28.5 tonnes. The new Cargo range proved popular with Ford’s extensive and loyal customer base, in addition to winning many conquest sales. As with every new truck model, there were a few disgruntled customers reporting various teething issues, but the truck’s ever-busy development team soon ironed out these gremlins.

In autumn 1982, Ford declared its intention to mix it with the big boys and introduce a Cargo it for 32-tonne operation. At the time, the writing was almost on the wall for its overweight Transcontinental big brother, so Ford adverts naturally headlined the potential 22.5 tonnes of payload offered by the Cargo 3220 unit. Powering this trimmest of tractors, and eight model variants, was a Deutz air-cooled, V6 engine that developed 204hp. The performance of this 9.6-litre motor was best described as adequate. To maintain maximum progress on the road it was necessary to keep the revs on the boil with the naturally aspirated Deutz and make full use of ZF’s 12-speed, synchromesh splitter bolted to its lywheel housing.

Benefitting from major redesigns

For more traditional water-cooled fans, a 10.5-litre, Perkins V8 540 could also be speciied. The lighter Cargo was not forgotten either, as Ford’s new Dover 90-150 series also debuted in 1982. These retained the same characteristics as their canted predecessors, but beneitted from major redesigns to the block, head and crankshaft assemblies.

Ford kept the Cargo’s momentum fresh with regular investment and development, such as the factory-built sleeper cab that debuted at the Frankfurt Show in 1983. As the 1980s progressed, the Cargo’s model line increased to cover virtually every standard coniguration right across Europe and, accordingly, sales of the Berkshirebuilt truck were strong across the Channel.

A range of operators liked the Cargo’s solid performance levels and the fact that it was straightforward to service and repair. Parts costs and downtime igures proved to be among the best around and, in those days, Ford’s extensive back-up network was one of the CV market’s inest. A major landmark in the history of Ford Commercial vehicles and its Cargo range happened in 1986 when Iveco Ford Truck was born. A slump in sales at Ford attracted a takeover from the Italian manufacturer, whose presence in the UK was best described as modest, despite the organisation’s previous acquisitions of OM, Unic and Magirus-Deutz.

The fallout from this massive merger was never going to be easy to administer, but progress was made after dealership territorial squabbles and the new management team, mostly from Iveco, settled into their responsibilities. Some industry observers believed the amalgamation was a graceful way out of the truck business for Ford, whose top brass in the US never seemed satisied, despite the Cargo’s market-leading position.

Iveco retained the Langley plant for the time being and back then the 60-acre complex employed 1,700 people. By the late 1980s, in addition to introducing a 38-tonne tractor powered by an LT10.330 Cummins engine, lighter models of the Cargo made history by becoming the irst British truck at 7.5 tonnes and below, to have disc brakes itted all round. The new Cargos that were launched at that time also boasted a revamped cab and an enhanced suspension setup.

Time to say goodbye

After 11 years in production, Iveco phased out the Cargo and replaced it with a new Giugiaro-designed truck, which retained the same name in the UK, but was known as the

Eurocargo on the Continent. The newcomer covered weight ranges between 7 and 18 tonnes. A decade after its predecessor won the Truck of the Year award in 1982 this cutting-edge Cargo repeated the success. Production of the heavier, original Cargos continued until 1992, when Iveco launched the medium-heavy EuroTech series. Iveco closed Langley in 1997. The Cargo name continues today as the model is still made by several Ford subsidiaries and Freightliner Trucks. It is ironic that Ford’s range change to the Cargo became a transcontinental success story, when its big truck of the same name never quite managed that success. ■

KEEPING EDDIE STEADY

The Ford Cargo range played an important role during Eddie Stobart’s period of rapid expansion during the late 1980s and early 1990s. The attractive payloads offered by the light unladen weight of the Cargo chassis and cab saw Stobart use the range for a variety of applications, including general articulated work and specialist drawbar operations. The latter type proved ideal for high-volume/ low-weight work out of the nearby Metal Box factory and the firm’s distinctive rooftop sleeper conversion Cargos were eventually replaced by Daf XFs with factory-fitted attic accommodation.

Diana, an example from Stobart’s latest batch of 17-tonne Cargo rigids, made the headlines in the second edition of the Stobart Express in August 1991. Back then, boss Edward Stobart said the trucks were ideal for the increase of part-load movements in developing its secondary distribution market. That newsletter also spawned the birth of the Stobart spotting era: a letter from musician Jools Holland was reproduced on the back page, detailing his interest in seeing the company’s trucks on such a regular basis.

THE WINNER TAKES IT ALL

Less than a year after its launch, Ford’s Cargo collected the prestigious title of Truck of the Year in 1982. Winning by the clearest margin in the history of the contest, the Cargo accumulated a magnificent 50 points, trouncing Scania’s GPR range, with 34 points, into second place and Mercedes-Benz’s 1633/38 models took third with 31 points. Curiously, the Cargo’s modern looks barely received a mention in the judges’ plaudits, as the distinguished team from 12 voting countries were won over by the truck’s high-quality handling, serviceability and inherent flexibility of build specifications. Further awards would follow for the Cargo, which received a gong from the British Design Council for An Outstanding British Product in 1982 and by January 1993, the SMMT’s annual commercial vehicle registration figure confirmed the new Ford was Britain’s Best Selling Truck.

�

Ford was quick to advertise its triple award-winning success

SLIPPERY CUSTOMER

Concept Cargo broke cover in June 1984 and was the product of Ford’s Basildon-based advanced engineering team. Based on a 7.5-tonne box van chassis, the ground-breaking rigid came with a comprehensive aerodynamic makeover, in addition to several cutting-edge technical developments, all of which were expected to be part of any truck of the 1990s.

Windfoil of Norfolk constructed the body, which came with balsa wood sandwich side walls and plastic side skirts. The experimental 7.5-tonner was powered by a 6.2-litre turbocharged six-in-line engine, which had been despeeded and given a torque boost. A ZF overdrive-top gearbox replaced the usual direct-top ’box from this maker, as it coped better with the altered power output. Transferring the drive rearwards was a single piece propshaft made from araldite epoxy and carbon fibre. Cutting-edge Lucas Girling hydraulicallyoperated disc brakes, with asbestos-free pads, were concealed by trimmed steel wheels shod by experimental Dunlop tyres, while inside the cab redesigned storage and polycarbonate side windows were the most obvious features. Concept Cargo’s performance was electronically monitored by VEDAC (Vehicle Data Collection Device), This took the form of a removable cartridge that could be scanned back at base.