;how debut for Bonallack lemountable system

Page 89

If you've noticed an error in this article please click here to report it so we can fix it.

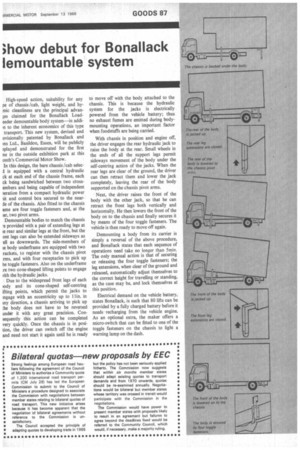

High-speed action, suitability for any pe of chassis /cab, light weight, and hymic cleanliness are the principal advan ;es claimed for the Bonallack Load eeder demountable body system—in addiin to the inherent economics of this type transport. This new system, devised and °visionally patented by Bonallack and ins Ltd.. Basildon, Essex, will be publicly splayed and demonstrated for the first ne in the outside exhibition park at this onth's Commercial Motor Show.

In this design, the bare chassis /cab selecis equipped with a central hydraulic ok at each end of the chassis frame, each ck being sandwiched between two cross embers and being capable of independent )eration from a compact hydraulic power

lit and control box secured to the nearde of the chassis. Also fitted to the chassis ame are four toggle fasteners and, at the ,ar, two pivot arms.

Demountable bodies to match the chassis .e provided with a pair of extending legs at te rear and similar legs at the front, but the ont legs can also be extended sideways as ell as downwards. The side-members of le body underframe are equipped with two rackets, to register with the chassis pivot rms, and with four receptacles to pick up he toggle fasteners. Also on the underframe re two cone-shaped lifting points to engage vith the hydraulic jacks.

Due to the widespread front legs of each ■ ody and its cone-shaped self-centring ifting points, which permit the jacks to :ngage with an eccentricity up to I lin. in my direction, a chassis arriving to pick up :he body does not have to be reversed under it with any great precision. Con sequently this action can be completed very quickly. Once the chassis is in position, the driver can switch off the engine and need not start it again until he is ready to move off with the body attached to the chassis. This is because the hydraulic system for the jacks is electrically powered from the vehicle battery; thus no exhaust fumes are emitted during bodymounting operations, an important factor when foodstuffs are being carried.

With chassis in position and engine off, the driver engages the rear hydraulic jack to raise the body at the rear. Small wheels in the ends of all the support legs permit sideways movement of the body under the self-centring action of the jacks. When the rear legs are clear of the ground, the driver can then retract them and lower the jack completely, leaving the rear of the body supported on the chassis pivot arms.

Next, the driver raises the front of the body with the other jack, so that he can retract the front legs both vertically and horizontally. He then lowers the front of the body on to the chassis and finally secures it by means of the four toggle fasteners. The vehicle is then ready to move off again.

Demounting a body from its carrier is simply a reversal of the above procedure, and Bonallack states that each sequence of operations need take no longer than 5min. The only manual action is that of securing or releasing the four toggle fasteners; the leg extensions, when clear of the ground and released, automatically adjust themselves to the correct height for travelling or standing, as the case may be, and lock themselves at this position.

Electrical demand on the vehicle battery, states Bonallack. is such that 80 lifts can be provided by a fully charged battery before it needs recharging from the vehicle engine. As an optional extra, the maker offers a micro-switch that can be fitted to one of the toggle fasteners on the chassis to light a warning lamp on the dash.