PNEUMAROTOR F OR SOLID FUELS

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

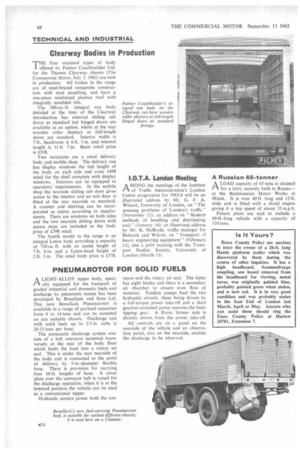

A LIGHT-ALLOY tipper body, specirA ally equipped for the transport of graded industrial and domestic fuels and discharge by pneumatic means has been developed by Bonallack and Sons Ltd. This new Bonallack Pneumarotor is available in a range of payload capacities from 6 to 14 tons and can be mounted on any suitable chassis. Discharge rate with solid fuels up to 2-5 in. cube is 20-35 tons per hour.

The pneumatic discharge system consists of a belt conveyor mounted transversely at the rear of the body floor which, feeds the load into a rotary air seal. This is under the rear nearside of the body and is connected to the point of delivery by 5-in.-diameter flexible hose. There is provision for carrying four 10-ft. lengths of hose. A cover plate over the conveyor belt is raised for the discharge operation; when it is in the lowered position the vehicle can be used as a conventional tipper.

Hydraulic motors power both the con veyor and the rotary air seal. The 'latter has eight blades and there is a secondary air chamber to ensure even flow of material. Tandem pumps feed the two hydraulic circuits, these being driven by a full-torque power take-off and a third gearbox-mounted pump operates the body tipping gear. A Roots blower unit is directly driven from the power take-off.

All controls are on a panel on the nearside of the vehicle and an observation panel, also on the nearside, enables the discharge to be observed.