Non-stop Gritters Keep Roads Clear

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

INTENSIVE methods need to be 'employed to keep traffic moving on Scandinavian roads during the winter months, the Municipality of Oslo providing a good example of the policy adopted. Here the gritting service operates 24 hours a day, seven days a week, from November to April. Large quantities of grit are required and a Simple but extremely practical procedure has been introduced.

Briefly, a large hole was blasted in a neighbouring Oslo hillside, a tunnel Large enough to admit vehicles was then cut beneath it and a hopper gate inserted so as to permit gravity discharge from the hole into the vehicles waiting in, the tunnel. During the summer, supplies of grit are tipped into the hole in the hill and in winter the gritter vehicles are fed through the hopper system. British gritting equipment is entering increasingly into this particular sphere.

The variable nature of the British climate has been an important factor in stimulating development of road gritting machinery, which is why British machines are now being employed in countries where winter conditions are far more severe and more prolonged than at home.

Actual gritting operations in Oslo are directed by a tele-communication system from the fleet headquarters and, advised by the local meteorological office regarding the probable trend of the weather, the superintendent gives directions to the drivers of individual vehicles to vary their routes, to change the intensity of spread, and otherwise 446 to amend procedure in order to meet the conditions of the moment.

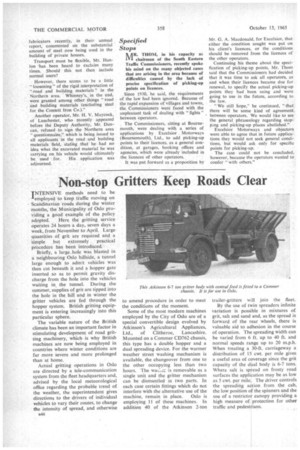

Some of the most modern machines employed by the City of Oslo are of a special convertible design evolved by Atkinson's Agricultural Appliances, Ltd., of Clitheroe, Lancashire. Mounted on a Commer CD762 chassis, this type has a double hopper and a dual spreading device. For the warmer weather street washing mechanism is available, the changeover from one to the other occupying less than two hours. The wa:..L.7,. is removable as a single unit and the gritter mechanism can be dismantled in two parts. In each case certain fittings which do not interfere with the alternative use of the machine, remain in place. Oslo is employing 11 of these machines. In addition 40 of the Atkinson 2-ton trailer-gritters will join the fleet.

By the use of twin spreaders infinite variation is possible in mixtures of grit, salt and sand and, as the spread is forward of the rear wheels, there is valuable aid to adhesion in the course of operation. The spreading width can be varied from 6 ft. up to 40 ft. and normal speeds range up to 20 m.p.h. When treating a 30-ft. carriageway a distribution of 15 cwt. per mile gives a useful area of coverage since the grit capacity of the dial body is 6-7 tons. Where salt is spread on frosty road surfaces the application may be as low as 5 cwt. per mile. The driver controls the spreading action from the cab, the low position of the spinners and the use of a restrictor canopy providing a high measure of protection for other traffic and pedestrians.