WHY STEAM WAGONS COST LESS

Page 74

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

TO RUN.

The Improvements Which Have Made for Economy. in Running Cost.

THE wire-drawing or loss of steam pressure, one of I_ the two things to which I referred in my previous article (issue of The Commercial Motor for February 21st) as being responsible for some of the loss of efficiency of the steam wagon is, in part, due to the fact that the steam has to traverse long ancl.comparatively small pipes on its way from the boiler to the engine. One of the claims made by sponsors of the overtype wagon is that it eliminates' that particular trouble because the engine is so close to the boiler as, practically, to obviate altogether any need for piping. Wiredrawing also occurs at the ports of entry into the cylinder when they are too small and when the valve gear is badly designed so that the valve opens and closes too slowly.

Diminishing Condensation Losses.

The need for short piping of ample diameter to reduce wire-drawing and properly lagged—that is to say, covered with non-conducting material so as to retain the heat in the steam and reduce condensation—was known when steam wagons first began to be made, but the knowledge does not appear to have been properly utilized. It almost seems as though makers of steam wagons in the early days were so proud and pleased that they could get a wagon which would run upon the road and carry a load' without giving much trouble that they did not think to concern themselves with what might thenhave, been regarded as fine points • of economy and 'maintenance. Steam wagons before the war, with one or two exceptions, were crudely designed and built -(considered in the light of contemporary engineering knowledge and practice). It needed the keen competition which developed after the war to stimulate the constructional faculties of steam-wagon designers, and the improvements which have been effected are such as to make the economy of performance of present-day steamers seem wonder

ful when compared with that of their pre war predecessors.

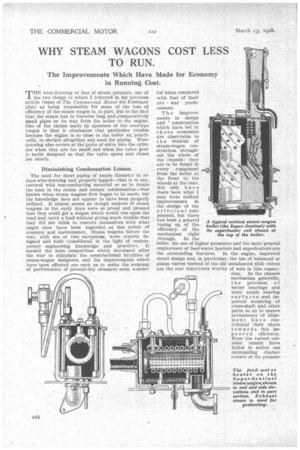

The improvements in design and ' construction which have led to these economies are observable to the 'student of steam-wagon con7 struction throughout the whole of the chassis : they are to be found itt every component from the Boiler at the front to the wheels at the rear. Not only have there been what I may term radical improvements in the design of the principal com7 ponents, but there has been a 'general tuning up of the efficiency of the mechanism right through. In the boiler, the -use of higher pressures and the more general

employment of feed-water heaters and superheater S are the outstanding features. In the engine, improved detail design and, in particular, the use of, balanced or piston valves instead of the old unbalanced slide valves are the new departures Worthy of note in this connec A typical vertical steam-wagon boiler (the Super-Sentinel) with its superheater coil shown at the top of the boiler.

• tion. In the chassis mechanism generally, t h e provision of better bearings and more ample bearing surfaces and. im proved mounting of cross-shaft and other parts so as to ensure Permanency of alignment have con tributed their share towards this improved efficiency.

Even the veriest out sider cannot have failed to notice one outstanding characteristic of the present

day steam Wagon, as compared with the older type, in the design of the steering gear. The Ackerman-type steering is now universal, as opposed to the old centrally pivotedgear which, although satisfactory up to a point anti having certain advantages, particularly in respect of ease of manceuvring in tight corners, nevertheless opposed unnecessary resistance to driving whenever anything like a sharp turn had to be negotiated.

Improvements in Boiler Construction. _ It is of interest to note the steps which have been. taken to promote economy in the production of the steam itself. There are three things which stand out: the use of higher working pressures, of feed-water heaters and of superheaters. Out of 11 steam wagons of pre-war construction only one utilized a steam pressure of 230 lb. per sq. in. There was one at 225, .seven at 200, one at 175 and one at 170. To-day, the standard working pressure is 220 lb. or 230 lb. per sq. in., and that, apparently, is likely to become in the near future obsolete as a standard pressure, since the latest type of wagon 'has .a boiler designed for a working pressure of 275 lb. per sq. in. Of those 11 wagons, only two were fitted with superheaters and only four had feed-water heaters: To-day, although these accessories are not universally favoured, they are, nevertheless, fitted to most steam. wagons.

For the benefit of the uninitiated it may be as well to explain just what are feed-water heaters and superheaters: The meaning of the first is almost clear. It is acontrivance adapted to heat the water before it enters the boiler. As a rule, this heating is effected by the exhaust steam from the engine which is passed through a coil of piping located in a box or casing through which t h e

water has to pass on Its way to the boiler. A superheater is used to add additional heat to the steam as it leaves the boiler. As a general rule, this fitting is a roil of piping located at the top or end of the boiler jUst at the entrance to the smoke stack. The steam passes through this tubing and in its passage is superheated, thus making use of heat in the flue gases which would otherwise be lost escaping up the chimney. Apart from all other consideration s, it is apparent that each of these fittings contributes, in its use, to the heat economy of the boiler. The first utilizes heat from the exhaust steam w h 1 ch. W ould otherwise be blown away into the atmosphere, the second similarly takes heat out of the gases which would otherwise pass away into the atmosphere up the chimney.

There are, however, further advantages, all of which bear their part in ensuring this improved economy which we have in mind. In the first place, the mere fact that the water enters the boiler warm instead of stone cold is in itself beneficial to the boiler, not merely as an aid to efficient steaming, but also as a means of reducing maintenance costs. One of the strains to whieh a boiler is subject, and one which is responsible for some of the ailments to which a steam-wagon boiler is more or less liable, is that due to the extremes of temperature to which -it is subject. Those extremes are, on the one hand, that of the entering-water and, on the other, that of the steam as it leaves, and more still, of cour.se, the hot gases which are passing through or around the boiler as the case may be. With a feed-water heater in use the initial temperature of the entering fluid is. of course, much higher and, in consequence the variation between extremes is less.

There is more, too, in superheating steam than merely the economy of heat from the boiler, which is effected by making use of it in the manner described. Steam, as every driver of an old steam wagon knows, is liable to pass over from the boiler carrying with it a small percentage of the water with which it is in contact. At its worst, this failing is known as priming. Priming, of course, is generally due to other causes, such as the presence of impurities in the water, and when it occurs to any appreciable extent the driver has to empty his boiler and thoroughly clean it in order to eradicate the trouble. Superheated steam does not carry water over with it, because any water is dried out in the superheater, so that the steam leaves in a perfectly dry state, so dry, indeed, that it can stand a certain amount of cooling and still remain dry steam. That is to say, superheated steam is less liable to condensation than ordinary saturated steam (as it is called when it is

used as it -comes from the water, or, as the technicians say, in contact with the water from which it is evaporated).

It is fairly simple to understand that the use of feed-water heaters and superheaters. conduces to economy. The reader will find that, even where a steam-wagon user does not employ the former of these two components, his reasons are not that he denies the economy of heat 'bnt that, in his view, there are certain disadvantages which outweigh the 'economies effected. The economy resulting from the use of steam at higher initial pressures, as for example, 275 lb. per sq.in., instead of 230 lb., or even 230 lb. instead of 200 lb. is not so easily understood. -To enter into a discussion of that point would involve us in technicalities which would be out of place-in-----this series of articles. It will be enough, I think, if state that, other things b-e n g equal, it is generally recognized that t h e higher the working pressure the greater the overall efficiency and economy of the boiler and engine, considered as a heatproducing and using

unit. COMPOITND.