HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble,

346.—Adjusting Differential on Sentinel Steam Wagon.

In some cases, where the differentials of Sentinel steam wagons have been dismantled, it has been found that the sleeve carrying the bevel driving wheel has been forced too far along the axle shaft, thereby forming a burr on the end of the sleeve through its butting against the shoulder on the axle which carries the chain wheel. The movement of the sleeve sometimes causes binding of the differential. It also results in considerable wear of the sides of the back axle bushes, which are carried in axle boxes bolted to the rear springs. This trouble is canned by inserting too thick a thrust washer at the end of the sleeve when the differential is being adjusted. The best method of overcoming the trouble, when the bevel pinion teeth are not worn too badly to justify their renewal, is to reduce the boas at the bottom of each and to add a steel washer at the top. The amount taken off and the thickness of the washer utilized depend upon the position of the sleeve, the adjustment of which should only require a standardsize washer of the correct thickness. The fitting of such a washer and the alterations to the pinions to which we have referred will automatically bring the chain wheel, springs and axle bushings into their correct alignment.

347.--Tightening Engine Flywheels.

On some makes of engine a certain amount of trouble is experienced owing to the flywheels working loose. In one case which has been brought to our notice three out of the six bolts holding the flywheel to its flange on the crankshaft had sheared,' whilst the nut sl on the remaining bolts were loose.

If. such a trouble occur, the old bolts should be removed and replaced by new ones slightly longer and a very good fit in the holes of the crankshaft and flywheel. Spring washers should be used behind the nuts, and after the latter are tightened the ends of the bolts can be riveted over to ensure security.

In some cases, of. course, split-pinned nuts are employed ; when this is so, the nuts may be screwed well home, and the splitlpin holes drilled in position if the holes already existing do not exactly coincide with the eastellations.

B42

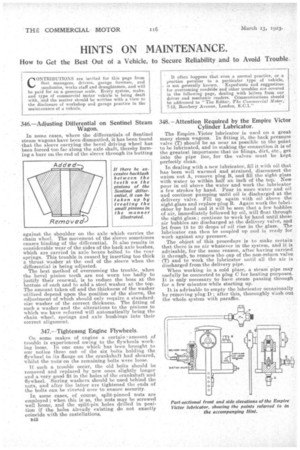

348.—Attention Required by the Empire Victor Cylinder Lubricator.

The Empire ,Victor lubricator is used on a great many steam wagons. In fitting it, the back pressure valve (T) should be as near as possible to the point to be lubricated, and in making the-connection it is of the greatest importance that no filings, dirt, etc., get into the Pipe line, for the valves must be kept perfectly clean.

In dealing with a new lubricator, fill it with oil that has been well warmed and strained, disconnect the union nut A, remove plug B, and fill the sight glass with water to within half an inch of the top. Now pour in oil above the water and work the lubricator a few strokes by hand. Pour in More water and oil and continue pumping until oil is discharged at the delivery valve. Fill up again with 'oil above the sight glass and replace plug B. Again work the lubrichtor by hand and it will be seen that a few bubbles of air, immediately followed by oil, will float through the sight glass ; continue to work by hand until these air bubbles are discharged at the delivery valve, and let from-15 to 20 drops of .oil rise in the glass. The lubricator can then be coupled up and is ready for work against any pressure.

The object of this procedure is to make certain that there is no air whatever in the system, and it is advisable, for the same reason, after having carried it, through, to remove the cap of thG non-return valve (1) and to work the lubricator until all the air is . discharged from the delivery pipe.

When working in a cold place, a steamr pipe may usefully be connected to plug C for heating purposes. It is only necessary to have steam passing through for a few minutest while starting up.

It is advisable to empty the lubricator occasionally by removing plug D; after this, thoroughly wash out the whole system with paraffin. Should the sight glass become brciken, simply 'open valve E and the lubricator will continue working quite satisfactorily. Do not let the lubricator work itself empty. Therefore, fill it regularly.

The gears in the driving lever H and in the boss G must be kept perfectly clean and, to ensure this, paraffin should be flushed through them, by means of the two oil cups, at least three times a week.