A FORD TON TRUCK AS A BATTERY ELECTRIC.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

A Very Interesting Conversion. Would it be Economical ? Would the Advantages Gained Justify the Cost ?

TO THOSE owners of Ford one-formers whose business lies in congested areas, and whose work is therefore of a many-stop, limited daily mileage description the following details of an unusual conversion of an old Ford Qne-tonner, carried out by the writer, may he of some interest:—

The round served by this vehicle was limited to a daily distance of about 30 miles, with frequent stoppages of fairly long duration, so that the wear and tear on the engine and gears were out of all proportion to the mileage run, and the petrol consumption was naturally very high.

The urgent necessity for .a thorough overhaul, entailing considerable engine renewals, led to the adoption of the revolutionary scheme of substituting an electric motor for the engine and gears and the provision, of pannier boxes for the accommodation of a battery of accumulators of sufficient capacity to assure a run of about 35 miles per charge.

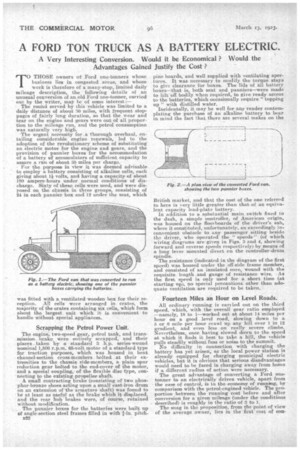

For the purpoee in view it was deemed advisable to employ a battery consisting of alkaline cells, each giving about avolts, and having a capacity of about 180 ampere-hours under normal conditions of discharge. Sixty of these cells were used, and were disposed on the chassis in three. groups, consisting of 24 in each pannier box and 12 under the seat, which was fitted with a ventilated wooden box for their reception. All cells were arranged in crates, the majority of the erates containing six cells, which form about the largest unit which it is convenient to handle without special appliances.

Scrapping the Petrol Power Unit.

The engine, two-speed gear, petrol tank, and transmission brake were entirely scrapped, and their places taken by a standard 3 h.p. series-wound nominal 1,800 r.p.m. 65-volt motor of a standard type for traction purposes, which was housed in bent channel-section cross-members belted at their extremities to the chassis side-members, a plain spur reduction gear bolted to the end-cover of the motor, and a special coupling, of the flexible disc type, connecting to the existing propeller shaft. A small contracting brake (consisting of two phosphor-bronze shoes acting upon a small east-iron drum on an extension of the armature shaft) was found to • he at least as useful as the brake which it displaced, and the rear hublerakes were, of course, retained without modification.

The pannier boxes for the batteries were built up of angle-section steel frames filled in with pitch. n22 pine boards, and well supplied with ventilating apertures. It was necessary to modify the torque stays to give clearanee for boxes. The lids of all battery boxes—that is, both seat and panniers—were made to lift off bodily when required, to give ready access to the batteries, which occasionally require "topping up" with distilled water. Incidentally, it may b-e well for any reader contemplating the purchase of an alkaline battery to bear in. mind the fact that there are several makes on the British market, and that the cost of the one referred to here is very little greater than that of an equivalent capacity lead-plate battery.

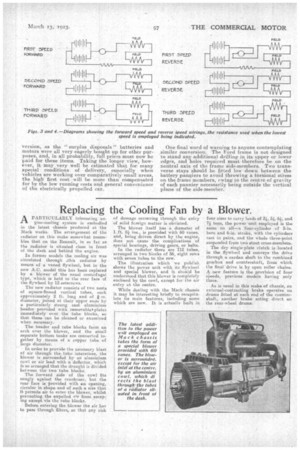

In addition to a substantial main switch fixed to the dash, a simple -controller, of American origin, was housed on the floorboards of the driver's oab, where it constituted, unfortunately, an exceedingly inconvenient obstacle to any prassenger sitting beside the driver, who operated the " speeds" (of which wiring diagrams are given in Figs. 3 and 4, showing forward arid reverse spCeds respectively) by means of a long lever mounted direct en the controller-drum spindle. The resistance (indicated in the diagram of the first speed) was housed under the off-side frame member, and consisted of an insulated core, wound with the requisite length and gauge of resistance wire. As the first speed is only used for a short time (at starting up), no special precautions other than adequate ventilation are required to be taken.

Fourteen Miles an Hour on Level Roads.

All ordinary running is canted out on the third speed, which„ with the overall -gear ratio employed —namely, 18 to 1—worked out at about 14 miles per hour on a good level road, slowing down to a 5 or 6 mile per hour crawl up any hill over I in 12 gradient, and even less on really severe climbs. Nevertheless,. once having slowed down to the speed at which it finds it best to take a hill, the vehicle pulls steadily without fuss or noise to the summit. No difficulty _in connection with charging the battery has yet arisen, as the local power station is already equipped for charging municipal electric vehicles, but it is obvious that serious disadvantages would need to be faced in charging away from home if a different radius of action, were necessary.

The great advantage, of converting a Ford onetonner to an electrically driven vehicle, apart from the ease of control, is in the economy of running, by comparison With the petrol-engined vehicle. The proportion between the running cost before and after conversion for a given mileage (under the conditions described) is roughly in the ratio of 3 to 1. The snag in the proposition,-from the point. of view of the average 'Owner, lies in the 'first cost of con

version, as the. "surplus disposals" batteries and motors were all very eagerly bought up for other purposes, and, in all probability, full prices must now be paid for these items. Taking the longer view, however,. it may very well be estimated that for many special conditions of delivery, especially when vehicles are working over comparatively small areas, the highfirst cost will be more than compensated for by the low running costs and general convenience of the electrically propelled car. One final word of warning to anyone contemplating similar conversion. The Ford frame is not designed to stand any additional drilling in its upper or lower edges, and holes required must therefore be on the neutral axis of the frame side-members. Two transverse stays should be fitted low down between the battery :panniers to avoid throwing a torsional sti-ess on the frame members, cwing to the centre of gravity of each pannier necessarily being outside the vertical plane of the side-member.