An Adaptation for Unloading Cotton Goods.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

The First Step Towards the Reduction of Congestion at Manchester Warehouses.

Increasing attention is likely to be given, week by week, in the industrial districts which surround Manchester,. to he pressing demand for a revolutionary change in the method of offloading horse-drawn and motor-driven vehicles when they arrive at the merchants' and packers' warehouses. If it were possible to redesign and to rebuild the hundreds of warehouses at which bundles of cotton cloth are daily received in huge numbers, the problem that is presented would not be difficult of solution. A radical change of that kind, however, is one that does not come within the range of immediate business possibilities: in the first place, 10 or more years would have to elapse before any high percentage of the warehouses eould be so reconstructed ; in the second place, the capital outlay has to be reckoned. Whilst it is admitted that warehouses which are being built on new or cleared sites will probably be arranged with more regard to modern requirements as regards the reception or delivery of cotton or other goods, and internally as regards the rapid transference of those goods from floor to floor by means of suitable hoists or lifts, it is also very keenly felt that some relativelycheap yet effective system must be adopted before very long in place of the costly and slow method of porterage which is now the vogue.

The Seriousness of Existing Delays.

Merchants, packers, shippers and warehousemen in Manchester—in fact, everybody who has business interests in or around the city—are now at their wits' end to know how to reduce traffic congestion. Even when as many as five men are available for the purpose of handling a load of cloth of which delivery is tendered, two of the men on the lorry and three of the men carrying, a load of five tons of cloth, consisting on the average of some no bundles, can seldom be got rid of, in practice, to the point when the cart may move along and make room for another, in less than 11 hour. In those cases, and they are many, in which the receiving facilities are poor, or in which the porters have to carry the bundles up one or more flights of stairs, the time that is occupied is much higher. Thus it comes about that carting contractors are less and less ready to give a quotation by the piece, or by the load, and are now generally insisting upon the payment of so much per hour or per day, regardless of the effective work that is accomplished. It is not going too far to state that under obtaining conditions in the Manchester streets, for one hour of effective delivery work, there are commonly 211hours of waiting to be borne.

Rapidity of Handling Essential.

How can the foregoing position be improved? That question, indeed, has exercised the mind of many a Manchester man, but so far with no definite or concrete evidence of a solution. The greatest trouble is at the older warehouses, where there is often only a single loading place. At such as these, the congestion and delay is worst of all.

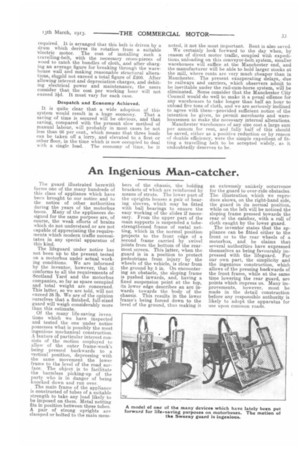

On the occasion of the recent Manchester Show, we were afforded the opportunity to inspect an admirable and inexpensive system which promises well. This is an adaptation of the conveyor-belt or travelling band, such as is oommon in many colliery operations, and is the outcome of the observational powers of a gentleman who is very well known indeed throughout the Lancashire cotton trade. He is a man with years of experience in the handling of goods at Manchester and elsewhere, and he knows all that there is to know about the conditions which exist in the various handlings and rehandlings that occur between warehouse and ship. He has realized, as a staunch believer in the extended use of commercial motors, that one of the greatest handicaps is found in the terminal delays, and that is why he has erected the travelling belt, suitable for the elevating of cotton cloth to the first or higher floors of a warehouse, on the lines of our illustrations.

The Daily Round in Manchester.

Cotton manufacturers usually send their productions, loaded upon "fiats," by railway, and deliver them to the railway by noon on the day before that on which delivery in Manchester is necessary. In the case of motor-carrying, they are frequently not loaded at the mill until 6.30 p.m., and sometimes on the actual morning of town delivery, which is a great advantage. In the latter event, of course, they arrive in the city of Manchester before the traffic becomes congested, but they are seldom able to make two calls before congestion occurs. A simple relief is to have each warehouse fitted with a continuous belt, communicating from the ordinary lorry-platform level to the floor on which the goods are required. It is arranged that this belt is driven by a drum which derives its rotation from a suitable 'electric motor. The cost of installing such a travelling-belt, with the necessary cross-pieces of wood to catch the bundles of cloth, and after charging an average figure for breaking through the warehouse wall and making reasonable structural altera, tions, shajald not exceed a total figure of £200. After allowing interest and depreciation charges, and debit, ing electrical power and maintenance, the users consider that the cost per working hour will not exceed aid. It must vary for each case.

Despatch and Economy Achieved.

It is quite clear that a, wide adoption of this system would result in a huge economy. That a saving of time is secured will be obvious, and that saving, compared with the present slow method of manual labour, will probably in most cases be not less than 66 per cent., which means that three loads can be taken off a lorry, and elevated to a first or other floor, in the time which is now occupied to deal with a single load. The economy of time, be it noted, it not the most important.. Rent is also saved. We certainly look forward to the day when, by reason of direct motor traffic, eoupled with expeditious unloading on this Conveyor-belt system, smaller warehouses will suffice at the Manchester end, and the manufacturer will be able to hold larger stocks at the mill, where rents are very much cheaper than in Manchester. The present exasperating delays,. due to railways and carriers, which observers admit to be inevitable under the rail-cum-horse system, will be eliminated. Some consider that the Manchester City Council would do well to make it a penal offence for any warehouses to take longer than half an hour to unload five tons of cloth, and we are seriously inclined to agree with them—provided sufficient notice of the intention he given, to permit merchants and warehousemen to make the necessary internal alterations.

Manchester warehouses of any size cost a large sum per annum for rent, and fully half of this should be saved, either as a positive reduction or by reason or double efficiency, were the simple expedient of fitting a travelling belt to be accepted widely, as it undoubtedly deserves to be.