Clean Sweep In Wandsworth

Page 67

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

ably possible. Constantly, of course, his efforts were offset by a public who in general terms were apathetic to his task. In wet weather paper and leaves would stick to smooth paving slabs so efficiently that the most vigorous brushing by the sweeper barely made an impression, nor was an open shovel an answer to a swirling wind.

So the traditional scene was classic. Tools of the trade so normal to the environment in which we live that modern development almost adopted their existence with a nod of approval.

However, within the London Borough of Wandsworth thoughts were being directed towards the future. The council was very much aware of costs and the relationships that these bore to quality standards. ible and, if so, what are the advantages to be gained?

O What effect would such a programme have upon the men now in the service, and what would have to be done to safeguard their interests?

O Would such a programme, and the end product, be a final answer, or would this only be a short-term solution, with further steps to be taken over a much longer term?

O What would the long-term effects be, and what planning must be put into action?

Answering these questions was not difficult. It was agreed that the present street cleansing and ancillary services was a most costly sector of the borough engineer's department. It was also felt that although men street parking conditions.

b To contact the manufacturers and examine all various types of mechanical cleansing equipment now in use, or being developed, anywhere in the world.

c To pursue a policy of close contact and formal communication with the cleansing personnel through their official representative and trade union officials.

The first of these activities quickly identified and quantified the main categories of on-street parking. These were: 1. Clearway with no roadside parking.

2. Scattered with intermittent roadside parking.

3. Congested with "nose to tailroadside parking. In addition to this parking information

it was also noted that pedestrian footway traffic would in no way inhibit the use of a pavement-mounted suction vehicle.

The second activity, that of contacting various manufacturers of cleansing vehicles, took a longer period of time and involved meetings with many trade officials from foreign embassies. However, after trials with machineS and meetings with their manufacturers, it was considered that, having regard Co the requirements of the area, the following equipment was the most appropriate:

(a) For clearways with no roadside parking—

The Johnston Mechanical Suction Sweeper was selected. These machines would be used for cleansing about 36 per cent of the 503 channel miles in the borough and would be used on a day and night shift basis.

These machines were purchased from Johnston Eros. of Dorking, mounted on the Ford D750 chassis with six-cylinder diesel engine, to conform with the council's standardization plans. They are fitted with dual steering and controls to enable one-way street systems to be swept.

(b) For scattered and intermittent parking—

The Verro City suction sweeper was found to be suitable for sweeping these road channels, which amount to 40 per cent of all channels in the borough.

These machines are designed and manufactured by A. B. Asbrink and Co. of Malmo, Sweden, there being no machine of this type manufactured in the British Isles. They are highly manoeuvrable, enabling them to sweep successfully in scattered parking areas. Although of Swedish design, these machines are fitted with the Perkins 4/108 diesel engine and Lockheed braking system.

(c) For areas congested with "nose to tail" parking—

The final category comprises the remaining 24 per cent of channels. These cannot be efficiently swept by any presently known mechanical suction device. Because of this a piece of equipment suitable for this purpose has been devised by the borough and is now being assembled. Locally this has been called the "Wander Hose".

The question of sweeping pavements by a suction machine was equally fully explored. The possibility of using a footpath suction sweeper had been realized for some while and single machines had been in extensive use since 1966. After many trials it was found that the suction cleaner manufactured by Applied Cleaning Economics Ltd., of Falkirk, Scotland, was the most satisfactory for this borough's use.

These machines are fitted with the Villiers 147 c.c. four-stroke engine and are lighter than the normal street orderly barrow. Certain modifications were made to the council's instructions, viz., a larger petrol tank fitted to enable the machines to operate for the full eight-hour shift, sand boxes provided for dog foulings and pannier bags fixed for the personal belongings of the operator.

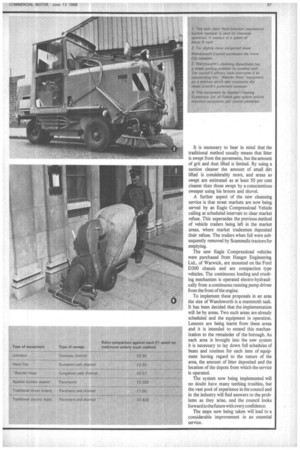

Throughout the investigations costs have been a prime consideration. It is significant, therefore, to note from the following table that to cover a combination of pavement and road channel with a suction machine the cost per mile varies between 30 per cent and 38 per cent less expensive than the traditional method of using an orderly truck to cover both. The figures used include all labour charges, overheads and depreciation costs: It is necessary to bear in mind that the traditional method usually means that litter is swept from the pavements, but the amount of grit and dust lifted is limited. By using a suction cleaner the amount of small dirt lifted is considerably more, and areas so swept are estimated as at least 50 per cent cleaner than those swept by a conscientious sweeper using his broom and shovel.

A further aspect of the new cleansing service is that street markets are now being served by an Eagle Compressload Vehicle calling at scheduled intervals to clear market refuse. This supersedes the previous method of vehicle trailers being left in the market areas, where market tradesmen deposited their refuse. The trailers when full were subsequently removed by Scammells tractors for emptying.

The new Eagle Compressload vehicles were purchased from Hanger Engineering Ltd., of Warwick, are mounted on the Ford D300 chassis and are compaction type vehicles. The continuous loading and crushing mechanism is operated electro-hydraulically from a continuous running pump driven from the front of the engine.

To implement these proposals in an area the size of Wandsworth is a mammoth task. It has been decided that the implementation will be by areas. Two such areas are already scheduled and the equipment in operation. Lessons are being learnt from these areas and it is intended to extend this mechanization to the remainder of the borough. As each area is brought into the new system it is necessary to lay down full schedules of beats and routines for each item of equipment having regard to the nature of the area, the amount of litter deposited and the location of the depots from which the service is operated.

The system now being implemented will no doubt have many teething troubles, but the vast pool of experience in the council and in the industry will find answers to the problems as they arise, and the council looks forward to the future with every confidence.

The steps now being taken will lead to a considerable improvement in an essential service.