For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the tender of the best letter which We publish on this page ; all others are paid for at the rate of a penny a him, with an allowance for photographs. All notes are edited before being published. Mention your employer's mime, in confidence, as evidence of good faith, Address. D., 31. and F., "The Commercial Motor," 7-15, Itosebery Avenue, London, E.C. 1.

Lamps Alight— On Saturday, the 15th June, light your lamps at 9.46 in London, 10.58 in Edinburgh, 10.14 in Newcastle, 10.9 in Liverpool, 9.59 in Birmingham, 9.56 in Bristol, and 10.52 in Dublin.

Adapting a Zenith Carburetter for Petrol.

The sender of the following communication has been awarded the Ws. prize' this week.

[1867] " A.E.K." (Derby) writes :—" Notwithstanding the very widespread use of gas amongst COMITERUAL Moron readers, there have been very few suggestions in your D., M. and F.' pages pa to methods of adapting carburetters and so on for use with this fuel. It recently fell to my lot to convert a Zenith carburetter to gas, and as I had at the same time to keep everything in order so that petrol could be used as an alternative fuel, the method which I adopted will, I am sure, be of interest. " In the first place, it was necessary to find the best position for the gas inlet pipe, and I tried by first of all introducing it through one of the air ports. So fitted, however, I discovered very quickly that it would be necessary to plug up at least one of these air ports, and this would not be possible in view of the necessity to he able to switch over to petrol. " Next I tried drilling the carburetter through the centre of-the-choke tube, so that the gas inlet came in through the choke tube at a point a little above the jet. For some reason, however, with the gas inlet in this place, the engine was very sluggish, particularly when fully loaded. Finally, therefore, I plugged this hole up and drilled a second one half an inch below the lowest edge of the throttle valve when the latter was closed. So far so good, but I had still, as readers who have used gas will readily understand, far too much 'air coming in through the regular air ports of the carburetter. I therefore fitted each of them with shutters, as shown on the sketch herewith [which we have had redrawn.—En.], of which sketch the following is an explanation : About I in. from the outer end of each air port I drilled vertically a, in. hole right through both walls.. I procured some pieces of / in. round iron, screwed them at one end, bent them at right angles so that, when fitted in the holes in the carburetter and nutted up at the free end the bent portion would bind in the hole and thus act as a, bolt-head. On each of these I soldered a small collar, the outer face of which was I in. from the centre of the bolt, so that when the bolt was in place, with the right-angled portion pointing outwards from the carburetter, the face of this collar' was level with the outer face of the port. Shutters were then cut from ?if in. brass plate to the shape shown in the sketch, one of the projecting flaps being drilled / in. clearance hole to fit on the bolts, the other being used merely as a handle. These plates were held in place by in. nuts as shown, a light compression spring being fitted under the nut so that the shutter would not move as a result of vibration. When using gas two of these air ports were closed. When turning over to petrol, it was only necessary to swing the shutters out of the way and the requisite air could then pass."

An Emergency Cardan Shaft Repair.

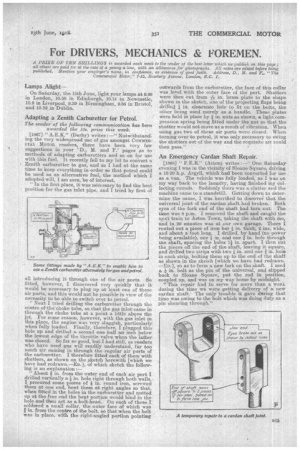

[1868] " (Acton) writes :—" One Saturday evening I was in the vicinity of Sloane Square, driving a 16-20 .h.p. Argyll, which had been converted for use as a van. The vehicle was fully loaded, as I was on my way back to the laundry, having finished my collecting rounds. Suddenly there was a clatter and the machine came to a standstill. Getting down to determine the cause, I was horrified to discover that the universal joint of the cardan shaft, had broken. Both eyes of the fork end' of the shaft had torn out. The time was 8 p.m. I removed the shaft and caught the next train to Acton Town, taking the shaft with me, and in. 20 minutes was at ,our own garage. There I routed out a piece of iron bar l in. thick, 2-ins, wide, and about a foot long. I drilled, by hand (no power being available), one in. and one in. bole through me shaft, spacing the holes 1 in. apart. I then cut the pieces off the end of the shaft, leaving it square, and drilled two strips with two in. and one 13 in. hole in each strip, bolting them up to the end of the shaft as shown in the sketch [which we have had redrawn. —ED.], so as to form a new fork on the shaft. I used a in. bolt as the pin of the universal, and slipped back to Sloane Square, put the rod in position, coupled up, and was on my way home by midnight. "This repair had to serve for more than a week during the time we were getting delivery of a new cardan shaft.' The only trouble it gave daring that • 'time was owing to the bolt which was doing duty as a pin shearing through."