Solid Drive Cuts Fuel Costs

Page 55

Page 54

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon, A.M.I.R.T.E. Daimler Bus with Twiflex. Centrifugal Clutch Shows Economy under Varying Operating Conditions ; Willowbrook 66-seat Body Mounted Directly on Chassis FOR several years one of the most popular makes of double-decker chassis in Great Britain has been the Daimler. Its specification has varied according to the requirements of operators, but it has generally included a Gardner oil engine, hydraulic coupling, preselective gearbox and triple-vacuum-servo braking.

Whilst it cannot be denied that the fluid coupling used by the company is complementary to the pre-selective gearbox and, at the same time, gives a smooth, shockfree drive, it has always had the disadvantage that relative slip is permanently present between the driving and driven members of the coupling. This, naturally enough, results in a small proportion of the fuel consumed by the power unit being used to accommodate. this slip.

After much -development work, in conjunction with Compression Ignition, Ltd., Twickenham, the Twiflex automatic centrifugal clutch is now offered as an alternative to the fluid coupling. Its effect is to provide a solid drive between engine and gearbox with full torque transmission from 800 engine r.p.m. upwards.

Improvement in Fuel Consumption

The result, as shown by a two-day road test, has been a substantial all-round improvement in the fuelconsumption rate, whilst the design of the clutch has not in any way detracted from the smoothness of the transmission when compared with those chassis equipped with a hydraulic coupling. The bus tested was first shown to the public at the Scottish Motor Show last November, where it attracted much interest, not only by virtue of the centrifugal clutch but also because it had a low gearbox position which permitted the use of a Willowbrook 66-seat body having an overall unladen height of 14 ft.

Since that time, the bus has been on demonstration to municipal operators with extremely satisfactory results. A transport undertaking in the south of England, for instance, reports an average fuel-consumption rate of 14.7 m.p.g. over 3,325 miles of town and country service, whilst the oil consumption over the same period has been at the rate of 4,434 m.p.g.

Similarly, Walsall Transport Department, which has a batch of 66-seaters, each weighing 7 tons 7 cwt. unladen, in service with the Twiflex clutch, is receiving average figures of 10.5-11 m.p.g. from vihies engaged 16 in city service. It is, therefore, obvious that the figure obtained during my test form a typical picture of wha may be expected from this vehicle in service.

The Twiflex clutch consists essentially of a hub con nected directly to the engine flywheel. This huh carrie six trailing links, at the 'outer ends Of which are friction faced shoes. The inner pivots of the links are Metalastil rubber-bonded bushes, pre-loaded so that the shoes ar withdrawn from the surface of the driven -drum a idling speed.

As engine speed increases, the resistance of the bushe is overcome. The drive is thus taken up at an engin speed of 500 r.p.m. Slip continues until 650 r.p.rr and at this speed the clutch is capable of transmittin: full torque and no further engine acceleration can tak place until the speed of the two members is synchro nized. At this juncture the drive becomes solid.

The driven drum is connected .to the gearbox propelle shaft by a spring-loaded coupling. This coupling, conjunction with the rubber bushes of the driving link5. ensures that any snatch in the transmission is absorbe4 before it can be transmitted to the gearbox.

A further advantage of the Twiflex clutch is that no adjustments are required other than facing replacements. Thus, the periodic top-up attention required by fluid couplings can be dispensed with. The facings are in. thick and it is recommended that they should be replaced when the thickness at the leading edge of each shoe is reduced to in. From experience with vehicles already in service, it is apparent that no attention to the clutch would be required between major overhauls and that facing life in general service varies between 150,000 miles and 200,000 miles.

The modifications to the chassis, which have permitted the low overall height of 14 ft. with a conventional double-deck body, have been relatively simple. The gearbox position has been lowered to give a flat line across the tops g the chassis side members at this point, and the top of the differential pot has been slightly reduced in height to reduce the bump clearance necessary.

This has enabled Willowbrook to mount their body directly on top of the frame. Instead of having the conventional cross-bearers, the body is supported on outriggers bolted to the frame, thus saving 6 in. in height.

In addition to the details already described, the test chassis was fitted with a Gardner 6LW oil engine rated to develop 107 b.h.p. at the governed speed of 1,700 r.p.na., and a Clayton Dewandre triple-vacuum-servo braking system. It is a peculiarity of British bus operators that they generally specify this system in preference to compressed-air braking, reasoning that the latter could cause injury to passengers in emergency stops.

As shown by the braking figures obtained during the test, the triple servo, whilst suitable for buses running at 10 tons gross, is a little under-powered for a I2-ton vehicle. Realizing this, Daimler offer air-pressure braking, but the demand for the triple servo continues.

Equivalent to 65 Passengers

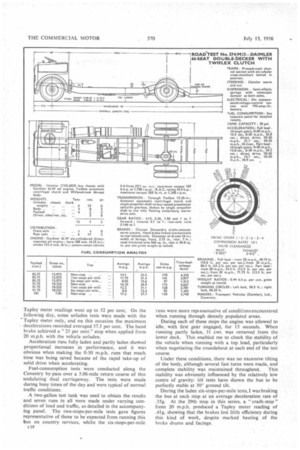

The double-decker was carrying iron weights totalling 4 tons 21 cwt. This was equivalent to approximately 65 passengers, and during all the tests I was accompanied by two other persons, making the total loading equivalent to a driver, conductor and 66 passengers. Rarely would a bus of this nature be carrying such a load during normal service runs, but I considered it to be as well to find out what the vehicle would do under the worst conditions. Later tests made with the lowerdeck payload removed were to return figures more akin to those averaged during normal service.

Having weighed the vehicle at the Coventry public weighbridge, I took the bus out to a level stretch of road adjacent to Baginton Aerodrome for braking and acceleration trials. With full load these were rather disappointing and from each speed the Tapley meter showed an average maximum deceleration of 42 per cent. During all these tests and subsequent ones, neutral was engaged before making a stop.

Later, tests were made partly laden and a definite improvement in stopping. d istances was shown, whilst the c17 Tapley meter readings went up to 52 per cent. On the following day, some unladen tests were made with the Tapley meter only, and on this occasion the maximum decelerations recorded averaged 57.5 per cent. The hand brake achieved a "25 per cent." stop when applied from 20 m.p.h. with the vehicle unladen.

Acceleration runs fully laden and partly laden showed proportional increases in performance, and it was obvious when making the 0-30 m.p.h. runs that much time was being saved because of the rapid take-up of solid drive when accelerating.

Fuel-consumption tests were conducted along the Coventry by-pass over a 5.06-mile return course of this undulating dual carriageway. The tests were made during busy times of the day and were typical of normal traffic conditions.

A two-gallon test tank was used to obtain the results and seven runs in all were made under varying conditions of load and traffic, as detailed in the accompanying panel. The two-stops-per-mile tests gave figures representative of those to be expected from running this bus on country services, whilst the six-stops-per-mile (-18 runs were more repi esentative of conditions encountered when running through densely populated areas.

During each of these stops the engine was allowed to idle, with first gear engaged, for 15 seconds. When running partly laden, 31 cwt. was removed from the lower deck. This enabled me to check the stability of the vehicle when running with a top load, particularly when negotiating the roundabout at each end of the test course.

Under these conditions, there was no excessive tilting of the body, although several fast turns were made, and complete stability was maintained throughout. This stability was obviously influenced by the relatively low centre of gravity: tilt tests have shown the bus to be perfectly stable at 30° ground tilt.

During the laden six-stops-per-mile tests,I was braking the bus at each stop at an average deceleration rate of .35g. At the 29th stop in this series, a " cras-h-stop " from 20 m.p.h. produced a Tapley meter reading of .41g, showing that the brakes lost little efficiency during this kind of work, despite marked heating of the brake drums and facings.

All the figures obtained during these tests show an improvement on those relating to contemporary chassis with fluid transmission running at similar weights. In addition to the fuel saving effected by the positive drive under normal running conditions, a further saving results from the action of the centrifugal clutch. It is possible with this transmission to select and engage first gear when waiting at a stop and then to select second ratio. With the engine idling and low gear engaged there is no power lost through the transmission, as occurs in similar circumstances with a fluid coupling. It is a common practice of bus drivers to engage low gear while waiting at a stop and this results in heavier fuel consumption.

There are no long and steep hills within casy reach of Coventry and time did not permit me to take the chassis on a prolonged hill-climb and brake-fade test.

Starting on a Hill A stop-start test was made, however, in Cash's Lane, Coventry, on a 1-in-10 gradient. On this slope the hand brake held the vehicle satisfactorily and it pulled away in low gear smoothly and confidently, although a certain amount of clutch slip was present. Another attempt, where the gradient approached 1 in 9, was not satisfactory, but it should be remembered that the bus was fitted with a • high-ratio axle and that operators covering hilly areas have the choice of ratios down to 6.2 to 1. The highest ratio available is 4.66 to 1.

I drove the vehicle through most of these tests and found it generally light to handle, particularly in steering. For normal stops, no excessive brake-pedal pressure is required and the gear-change pedal is not heavy in operation. Care must be taken to depress the pedal fully when making each change, otherwise the bus-bar will not engage the brake-band strut, resulting in a vicious kick-back of the gear-change pedal. Visibility from the driving position is particularly good and I was pleased to see that twin driving mirrors had been fitted, although no internal mirror was provided to afford a view of the platform area.

Passengers should have little to complain about in respect of personal comfort. Despite the virtually integral body and chassis construction there was no body vibration in either of the saloons, and under all conditions, the brakes and transmission acted smoothly. Engine noise in the lower saloon was slight, although the cushions of the rearward-facing front seats had been removed to accommodate the test tank. In the upper saloon there was little to betray the presence of the power unit. Body ventilation, although adequate downstairs, was less satisfactory upstairs.

Maintenance Tests

Several maintenance tasks were done at the Daimler works. Access to the radiator and engine is given by lifting the bonnet, which has a balancing support and can be fully opened in 2 seconds. A hinged prop to support the bonnet can be erected in 8 seconds.

With the bonnet open, the radiator water level was checked in 8 seconds and the engine-oil level was verified in 19 seconds, there being a long dipstick with a flexible extension at the rear of the crankcase. The oil filler is at the front of the crankcase on the near side, where it is easily reached by bulky oil jugs.

A Clayton Dewandre R.P. vacuumoperated automatic lubrication system fitted to the test vehicle dispensed with the need for greasing, except of the propeller-shaft and steering joints.

The reservoir for this system is located beneath the bonnet and its level was checked in 15 seconds. Removing the prop and lowering the bonnet occupied 7 seconds.

The gearbox is covered by a two-piece floor trap. Each section has three budget locks, and the right-hand section was removed in 31 seconds, 18 seconds being required for the other half. It is not necessary to remove the right-hand trap to reach the combined filler and level plug of the gearbox, and with the trap removed this level was checked in 20 seconds. This trap also provides access to the dynamo for inspection, lubrication and adjustment of the driving-belt tension. Replacement of the leftand right-hand traps occupied 35 and 28 seconds, respectively.. it

Access to the rear axle is .provided by a trap which was detached in 10 seconds and replaced in 13 seconds, the oil level in the axle being checked in 45 seconds. As the batteries were not in their normal position I did not perform timed maintenance tasks on them. No difficulties should be presented, as the batteries are beneath the front bulkhead scats and can be reached by removing the cushions.

No air cleaner is fitted to this chassis, but there is a coarse wire gauze at the cold-air intake in the top of the bonnet.

As Clayton Dewandre R.P. automatic brake adjusters were fitted to the test vehicle, no brake adjustments were carried out and, similarly, I did not attempt a sparewheel change, as no spare wheel was carried.

The inventor of the Twiflex coupling is Mr. C. W. Chapman, M.Eng., M.I.Mech.E., and he used a Daimler 2f-litre car with which to carry out his initial tests. These, together with the coupling, were fully described in The Commercial Motor dated January 11, 1952.