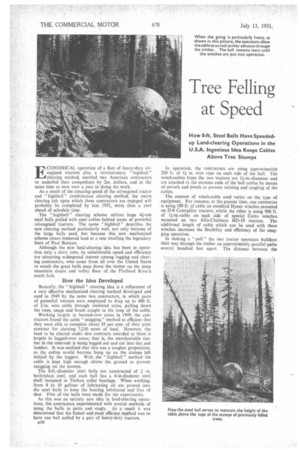

Tree Felling at Speed

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

ECONOMICAL operation of a fleet of heavy-duty oilengined tractors plus a revolutionary " highball " clearing method, enabled two American contractors to underbid their competitors by 2m. dollars, and at the same time to save over a year in doing the work.

As a result of the amazing speed of the oil-engined tractor and " highball " combination clearing method, the entire clearing job upon which these contractors are engaged will probably be completed by late 1952, more than a year ahead of schedule time.

The "highball" clearing scheme utilizes huge 4i-ton steel balls pulled with steel cables behind teams of powerful oil-engined tractors. The name " highball " describes the new clearing method particularly well, not only because of the large balls used, but because this new mechanized scheme clears timbered land at a rate rivalling the legendary feats of Paul Bunyan.

Although the new land-clearing idea has been in operation only a short time, its unbelievable speed and efficiency are attracting widespread interest among logging and clearing contractors, who come from all over the United States to watch the great balls snap down the timber on the steep mountain slopes and valley floor of the Flathead River's south fork.

How the Idea Developed Basically, the "highball" clearing idea is a refinement of a very effective mechanized clearing method developed and used in 1949 by the same two contractors, in which pairs of powerful tractors were employed to drag up to 400 ft. of 2-in, wire cable through timbered areas, pulling down the trees, snags and brush caught in the loop of the cable.

Working largely in burned-over areas in 1949, the contractors found the cable " snagging " method so efficient that they were able to complete about 95 per cent. of their joint contract for clearing 7,210 acres of land. However, the land to be cleared under new contracts awarded to them is largely in logged-over areas; that is, the merchantable timber in the reservoir is being logged out and cut into ties and lumber. It was .realized that this was a tougher proposition, as the cables would become hung up on the stumps left behind by the loggers. With the " highball " method the• cable is kept high enough above the ground to prevent snagging on the stumps.

The 8-ft.-diameter steel bails are constructed of I in. boilerplate steel, and each ball has a 6-in-diameter steel shaft mounted in Timken roller bearings. When working, from 8 to 10 gallons of lubricating oil are poured into the steel balls to keep the bearing lubricated and free of dust. Five of the balls were made for the experiments.

As this was an entirely new idea in land-clearing operations, the contractors experimented with several methods of using the balls in pairs and singly. As a result it was determined that the fastest and most efficient method was to have one hall pulled by a pair of heavy-duty tractors.

1110 In operation, the contractors are using approximately 200 ft. of l in. wire rope on each side of the ball. The winch-cables from the two tractors are 1-in.-diameter and are attached to the extreme ends of the ball cables by means of swivels and jewels to prevent twisting and tangling of the cables.

The amount of winch-cable used wines on the type of equipment. For instance, at the present time, one contractor is using 100 ft. of cable on standard Hyster winches mounted on D-8 Caterpillar tractors, whilst the other is using 900 ft. of 1i-in.-cable on each side of special Carco winches mounted on two Allis-Chalmers HD-19 tractors. The additional length of cable which can be used with these winches increases the flexibility and efficiency of the snagging operation.

In making a " pull " the two tractor operators bulldoze their way through the timber on approximately parallel paths several hundred feet apart. The distance between the tractors Varies with the type of terrain and the size of the trees to be snagged down. In light going the tractors move through the timber, snagging down trees caught in the loop of cable as they progress. However, in heavy stands of fairly large-diameter trees, the value of the winches becomes apparent.

The tractor operators permit the cable to unreel as they move ahead through the timber until they have played out most of the cable on the winches. They then anchor the tractors again.it trees or stumps and reel-in the cable on the winches. The tremendous increase in pull gained by using the winches in this manner makes it possible to pull down trees up to 4 ft. in diameter.

As the cable and ball crash through the timber as fast as a man can walk, all of the trees caught in the loop of cable are uprooted and felled as though they had been struck by a terrific hurricane. In addition to the almost unbelievable speed achieved, the " highball " clearing method is also much safer than standard clearing methods. By using their winches properly, tractor operators are always able to keep well clear of falling trees. The " highball " method uproots practically all of the large trees. Dead snags and some of the trees snap off like match-sticks when struck by the cable.

Small trees are frequently only partially uprooted or are bent over without breaking. However, in bending the small

trees, the cable scrapes the bark from one side. As a result, these small trees bleed and die quickly.

After the timber is snagged down, teams of tractors with bulldozer brush-blades move in to stack the trees and brush for burning.

Working on fairly level ground under ideal conditions, one pair of tractors pulling one ball snagged down nearly 200 acres of trees in 4 hours. The average daily production for one pair of tractors and one ball working under varying conditions, including steep hillsides, marshy ground, etc., has been close to 100 acres per 8-hour shift.

The equipment at present used by one contractor consists of the following:—Three 8-ft.-diameter balls, six HD-19 Allis Chalmers oil-engined tractors, two of them equipped with special capacity Carco winches, 12 D-8 Caterpillar tractors, D-7 Caterpillar tractors, and five special 15-ft. double-width dozers mounted on the HD-19s. The second contractor is using two 8-ft.-diameter steel balls, four DH-19 Allis Chalmers tractors, five D-8 Caterpillars, nine D-7 Caterpillars, three International Harvester TD-24 tractors, and one special machine comprised of two D-8 Caterpillars. The last-named machine consists of two tractors bolted together by a steel frame; it has one-man control and is complete with a 22 ft. special brush rake. This piece of equipment is capabie of doing the work of three tractors working singly.