THE NATIONWIE DISTRIBUTION OF A LIGHT

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

iLKY FOOD

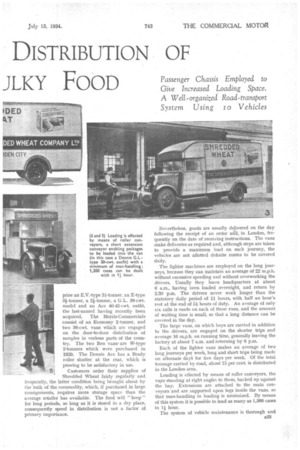

The Shredded Wheat Co., Ltd., Delivers 50 Per Cent. of its Output by Road in Large-capacity Vans Over a Distance of about ioo miles Passenger Chassis Employed to Give Increased Loading Space. A Well-organized Road-transport System Using io Vehicles

ALTHOUGH Shredded Wheat has been on the market ior many years, it was not until 1926 that the Shredded Wheat Co., Ltd., established its own Large factory at Welwyn Garden City, Herts, and ceased to import the commodity from Canada. That date is, for several reasons, memorable for the company. It marked the commencement of the manufacture in Great Britain of the Product, a striking increase in sales, the creation of manifold distribution problems and the General Strike.

The last-named event, involving the stoppage of railway services, was directly responsible for the formation of the company's own transport fleet, which, in the first instance, consisted of three Morris-Commercial 1-ton vans. It now comprises 10 units, most of the chassis being of the passenger type, on account of the increased loading space usually available, as compared with that of a conventional goods vehicle.

Shredded Wheat is a light, bulky commodity, which is packed in cartons each containing 12 biscuits, being distributed to the wholesalers in cases of 36 packets, each case weighing only 36 lb. The need for capacious vans of a light type is, therefore, obvious.

, The wheat from which the food is manufactured is of Australian origin, and is hauled by rail from the docks to the factory, where it is unloaded through a grille in the bay on to a conveyor, and is carried to the top floor of the building for the first process. There are also huge storage silos 117 ft. high and accommodating 5,500 tons of wheat.

Distribution is effected in equal proportions by road and rail, the company having railhead depots at Birmingham, Liverpool, Manchester, Bristol, Cardiff, Newcastle, Glasgow, Hull, Leeds, Nottingham and Edinburgh. Transport from those centres is effected by the B32

railway companies, using road vehicles or trains, according to local conditions and distance. Goods for. sale in Ire

land are dispatched from Liverpool. The Shredded Wheat concern's own fleet radiates from Welwyn over a distance of about 100 miles, serVing an

area bounded by Birmingham, Kettering, Peterborough, Cambridge, Ipswich, Colchester, Canterbury, Maidstone, Brighton, Portsmouth, South ampton, Reading and Oxford. In addition, the services of Carter, Paterson and Co., Ltd., are employed.

Goods for delivery to towns between Southampton and Exeter are carried by road, in the manufacturer's own vehicles, to the Southern Railway depot at Nine Elms, or to the Great Western Railway goods station at South Lambeth, Lon don, for shipment by rail.

The 10 vans, which are under the control of Mr. W. Scott, transport manager, are of Dennis, Morris-Commercial and Reo makes. The five Dennis vehicles corn

prise an E.V.-type 3j-tonner, an E-type

34-tonner, a 2i-tonner, a G.L. 30-cwt. model and an Ace 40-45-cwt. outfit, the last-named having recently been

acquired. The Morris-Commercials consist of an Economy 2-tonner, and

two 30-cwt. vans which are engaged on the door-to-door distribution of samples in various parts of the coun try. The two Rea vansare W-type 2-tanners which were purchased in 1929. The Dennis Ace has a Brady roller shutter at the rear, which is

proving to be satisfactory in use. Customers order their supplies of Shredded Wheat fairly regularly and frequently, the latter condition being brought about by the bulk of the commodity, which, if purchased in large consignments, requires more storage space than the average retailer has available. The food will " keep" for long periods, so long as it is stored in a dry place,

consequently speed in distribution is not a factor of primary importance.

Nevertheless, goods are usually delivered on the day following the receipt of an order add, in London, frequently on the date of receiving instructions. The vans make deliveries as required and, although steps are taken to 'provide a maximum load on each journey, the vehicles are not allotted definite routes to be covered daily.

The lighter machines are employed on the long journeys, because they can maintain an average of 22 m.p.h. without excessive speeding and without overworking the drivers. Usually they leave headquarters at about 6 a.m., having been loaded overnight, and return by 5.30 p.m. The drivers never work longer than the statutory daily period of 11 hours, with half an hour's rest at the end of 5i hours of duty. An average of only six calls is made on each of these runs, and the amount of waiting time is small, so that a long distance can be covered in the day.

The large vans, on which boys are carried in addition to the drivers, are engaged on the shorter trips and average 16 m.p.h. on running time, generally leaving the • factory at about 7 a.m. and returning by 6 p.m.

Each of the lighter vans makes an average of two long journeys per week, long and short trips being made on alternate day for five days per week. Of the total tonnage carried by road, about 75 per cent, is distributed in the London area.

Loading is effected by means of roller conveyors, the yaps standing at right angles to them, backed up against the bay. Extensions are attached to the main conveyors and are supported upon legs inside the vans, so that man-handling in loading is minimized. By means of this system it is possible to load as many as 1,300 cases in l hour.

The system of vehicle maintenance is thorough and 833

practical, and all normal repair and servicing work is carried out in the well-equipped workshops, but such tasks as regrinding and resleeving are entrusted to specialists. Each vehicle is inspected daily by a. mechanic and is subjected to a pit examination weekly, when greasing is also carried out. .

On an average, each machine receives a major inspection once every 10,000 miles, the engine being decarbonized, brakes adjusted and other major components examined and replaced if necessary. Bodywork is usually revarnished annually and is repainted as required, whilst each van is washed about twice weekly. Drivers are responsible for the cleanliness of their machines and for effecting minor repairs.

Monthly records of the cost of operating each vehicle ore compiled, these being summarized annually in the form of total figures for the whole fleet under the various headings of expenditure. The records show the mileage covered, the number of cases carried, gallons of fuel and oil consumed, the cost per mile, the cost per case and the number of cases per mile. Each unit of the fleet averages about 25,000 miles a year and the operating costs are, we understand, commendably low.

Comprehensive Daily Reports by Drivers.

The drivers make daily reports on sheets that provide for the following data, amongst other items :—The index numbers of the orders ; mileages between stops ; names of retailers to whom deliveries are made ; number of cases delivered ; length of time occupied in unloading ; times of leaving and returning to headquarters ; petrol and oil consumed ; total mileage covered according to speedometer; periods spent in loading at Welwyn, waiting at customers' premises and in cleaning vehicles ; and the time and place at which the statutory period of rest was taken and the distance covered up to that time.

Welwyn is an excellent centre for distribution, the roads radiating from it to all parts of the country being first-class. The large proportion of main-road work of the Shredded Wheat fleet, coupled with the light loading and the care exercised by the drivers, is reflected in the tyre mileages.

The tyres of the Dennis E-type van were in service for 00,000 miles before the first puncture was experienced, and they were not abandoned until they had covered 75,000 miles. Each tyre of the vehicles is numbered and a record is kept of its performance, an average life of 30,000-35,000 miles being obtained. Excellent service

has been obtained from Goodyear and India tyres, the latter having been purchased from Tyre Services (Herts and Beds), Ltd.

One of the most striking features of the Shredded Wheat organization is the generous treatment of the drivers and other employees. All of them are provided daily with luncheon free IA charge, they are well paid, drivers receive annually a week's holiday with pay, they have a rest room, each has a steel locker in which to keep his clothing, special care is taken to ensure that the maximum legal daily periods of duty are not exceeded and the men work for only live days per week. in addition, benefit schemes are in force. The wisdom of the policy of considerate treatment of the staff is proved by the results that are obtained.