PRACT

Page 40

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

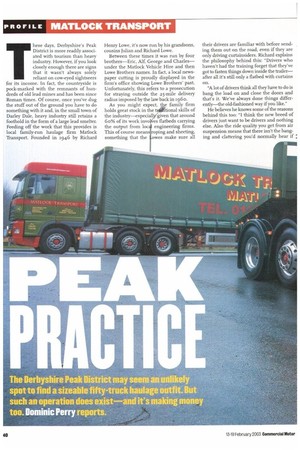

The Derbyshire Peak District may seem an unlikely spot to find a sizeable fifty-truck haulage outfit. But such an operation does exist—and it's making money

too. Dominic Perry reports. These days, Derbyshire's Peak District is more readily associated with tourism than heavy industry. However, if you look closely enough there are signs that it wasn't always solely reliant on cow-eyed sightseers for its income. In fact, the countryside is pock-marked with the remnants of hundreds of old lead mines and has been since Roman times. Of course, once you've dug the stuff out of the ground you have to do something with it and, in the small town of parley Dale, heavy industry still retains a foothold in the form of a large lead smelter. Feeding off the work that this provides is local family-run haulage firm Matlock Transport. Founded in 1946 by Richard

Henry Lowe, it's now run by his grandsons, cousins Julian and Richard Lowe.

Between these times it was run by four brothers—Eric, Alf', George and Charles— under the Matlock Vehicle Hire and then Lowe Brothers names. In fact, a local newspaper cutting is proudly displayed in the firm's office showing Lowe Brothers' past. Unfortunately, this refers to a prosecution for straying outside the 25-mile delivery radius imposed by the law back in 1960.

As you might expect, the family firm holds great stock in the tArtional skills of the industry—especiall given that around 6o% of its work invo es flatbeds carrying the output from loc4 engineering firms. This of course meansroping and sheeting, something that the 1.owes make sure all

their drivers are familiar with before sending them out on the road, even if they are only driving curtainsiders. Richard explains the philosophy behind this: "Drivers who haven't had the training forget that they've got to fasten things down inside the trailer— after all it's still only a flatbed with curtains on.

"A lot of drivers think all they have to do is bang the load on and close the doors and that's it. We've always done things differently—the old-fashioned way if you like."

He believes he knows some of the reasons behind this too: "I think the new breed of drivers just want to be drivers and nothing else. Also the ride quality you get from air suspension means that there isn't the banging and clattering you'd normally hear if omething isn't strapped down, but it doesn't top things moving about."

This point was brought home to him ecently after a Dutch artic pulling a curtainider dumped its load out of the rear doors, ight in front of his house. "You see it all the ime," he says. "They hit the first incline and he load just shoots out."

With this in mind the company takes care o put its inexperienced drivers on i7.5-toniers to start with—"nearly all our drivers tarted on four wheels," adds Richard.

Driver loyalty

1 rare sight in the industry is the high degree &driver loyalty. Julian claims that just two drirers have left the firm in the last couple of 'ears, and one of those was retiring after a 30'ear stint. He says this is due to a number of -actors, not least its stability: "It's down to the 'act that we've been in business for a number )f years and they feel secure here, they know hey aren't going to be out of a job at the end )f the week." There's also the trucks, which ire high-spec models with big cabs and big mgines, done out in Matlock's smart green ind red livery. Drivers use one vehicle, so they ire encouraged to keep their personal truck :lean and tidy. "We've got one driver who :ould tell if you'd been in his cab without :leaning your shoes first," says Richard.

It has expanded of late, taking on 15 new trucks in the last year and a half, with two more Dafs on the way. Julian says this is carefully managed growth. He explains: "To some degree we've had to put new trucks on the road just to survive, not necessarily to make any more money.

"Sometimes the haulier's mentality is not about how much money you're making, it's about how many trucks you've got on the road. There seems to be this ingrained philosophy that says you've got to show your success through the size of your fleet. It's almost growth for growth's sake."

Despite his reservations, Matlock Transport has seen its turnover grow by £300,000 in the last year, now standing at around £3.5m.

The majority of the artics are now run at .44 tonnes in order to boost their competitiveness, according to Julian. The same applies to two rigids on block work that have now been turned into drawbar units with 15m of floor space—effectively doubling their capacity. All these tweaks have been necessitated by the firm's key market—the UK's notoriously cash-strapped manufacturing sector. Julian is convinced that things will only get worse once the Working Time Directive comes along, something he describes as "the biggest challenge we will ever face".

He adds: "I think a lot of hauliers haven't faced up to it yet, because the only way to do that is to try and get a rate increase. I think a lot of people haven't realised its implications. The problem is that manufacturing is struggling against Far Eastern competition, therefore any increased rates will make them even less competitive and all that happens then is that we lose the work."

Part of the strategy to combat this has been the switch to 44 tonnes. The other has been to forge better relationships with its customers: "For instance, if a customer wants our driver to offload on site using its fork-lift then we'll do that Things like that allow you to develop a better relationship with the customer— there's no extra money there but it's one of the things you have to do," he says. "Years ago, when our dads were here, the answer to a request like that would have been no—but these days you've got to offer a wider range of services."

Battling on

Despite these looming problems, both Richard and Julian feel better placed than many firms to handle the upheavals coming in the next few years, not least because they will actually own their vehicles rather than being saddled with monthly lease payments.

"We've had knocks before and got over it; you've got to be a certain breed to work in haulage anyway. Our granddad was coming down here until he was 85 and we had problems getting both our dads to finish—it's just in the blood," says Richard.

There's been no talk of giving up, he adds: "We could probably sell up and live quite comfortably on the proceeds but there's fifty lads down here and we've had a lot of good work from them, so giving up wouldn't be fair on them. Whilst we're making money we'll keep battling on," says Julian determinedly.