Planned Swarf Reclamation ROPOSITION

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

By Ashley F. Taylor

TRANSPORT and handling of manufacturers' swarf present a number of problems which must be overcome if the material is to be effectively salvaged. The chief difficulty lies in the very nature of the swarf, for the stringy spirals of metal occupy space out of all proportion to their weight.

Even before the war, large establishments found the operation of a waste-material salvage department a profitable arrangement, but to-day the recovery of manufacturing waste is even, more important, both financially and to increase supplies.

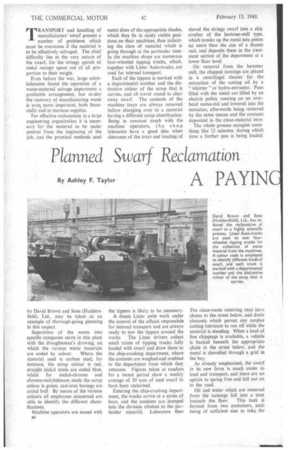

For effective reclamation in a large engineering organization it is necessary for the material to be under control from the beginning of the job, and the practical methods used by David Brown and Sons (Huddersfield), Ltd., may be •taken as an example of thorough-going planning in this respect Separation of the waste into specific categories starts in this plant with the draughtsman's drawing, on. which the various waste materials are coded by colour. Where the material used is carbon steel, for instance, the scrap colour is red; straight nickel steels are coded blue, whilst for nickel-chrome and chrome-molybdenum steels the scrap colour is green; cast-iron borings are coded buff. By means of the various colours all employees concerned are able to identify the different classifications.

Machine operators are issued with 136 metal discs of the appropriate shades, which they fix in easily visible positions on their machines, thus indicating the class of material which is going through at the particular time. In the machine shops are numerous four-wheeled tipping trucks, which, together with Lister Auto-trucks, are used for internal transport.

Each of the tippers is marked with a departmental number and the distinctive colour of the scrap that it carries, and all travel round to clear away swarf. The contents of the machine trays are always removed before changing over to a material having a different scrap classification. Being in constant touch with the machine operators, the shop labourers have a good idea when clearance of the trays and loading of the tippers is likely to be necessary.

A dozen Lister units work under the control of the official responsible for internal transport and are always ready to tow the tippers around the works. The Lister drivers collect small trains of tipping trucks fully loaded with swarf and draw them to the chip-crushing department, where the contents are weighed and credited to the department from which they emanate. Figures taken at random for a recent period show a weekly average of 50 tons of steel swarf to have been reclaimed.

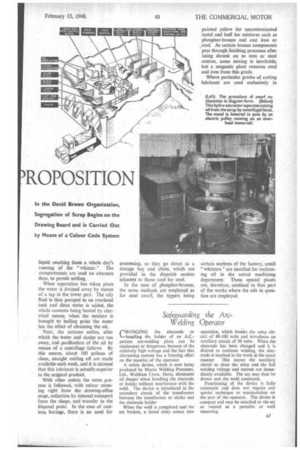

Entering the chip-crushing department, the trucks arrive at a series of bays, and the contents are 'dumped into the division allotted to the particular material. Labourers then shovel the stringy swarf into a chif, crusher of the hammer-mill type, which breaks up the metal into pieces no more than the size of a thumb nail, and deposits them in the treatment section of the department at a lower floor level.

On removal from the hammer mill, the chipped turnings are placed in a centrifugal cleaner for the extraction of the cutting oil by a " whizzer " or hydro-extractor. Pans filled with the metal are lifted by an electric pulley running on an overhead mono-rail and lowered into the extractor, afterwards being removed by the same means and the contents deposited in the clean-material bays The whole process occupies some thing like 12 minutes, during which time a further pan is being loaded.

The clean-waste receiving bays have chutes to the street below, and drain channels which permit any surplus cutting lubricant to run off while the material is standing. When a load of fine chippings is available, a vehicle is backed beneath the appropriate chute in the street below, and the metal is shovelled through a grid in the bay.

As already emphasized, the swarf in its new form is much easier to load and transport, and there are no spirals to spring free and fall out on to the road.

Oil and water which are removed from the turnings fall into a tank

beneath the floor. This tank is formed from two containers, each being of sufficient size to take the iqedtl .resulting from a whole day's running of the " whizzer." The compartments are used on alternate days, to permit settling.

When separation has taken place the water is drained away by means of a tap in the lower part. The oily fluid is then pumped to an overhead tank and clean water is added, the whole contents being heated by electrical means; IwIteia the mixture is brought to boiling ITK)int the water has the effect of cleansing the oiL Next, the mixture settles, after which the water and sludge are run away., and purification of the oil by means of a centrifuge follows. By this means, about 100 gallons of clean, straight cutting oil are made available each week, and it is claimed that this lubricant is actually superior to the original product.

With other metals the same process is followed, with colour routeing right from the drawing-office stage, collection by internal transport from the shops, and -transfer to the disposal point. In the case of castiron boring.% there is no need for

processing, so they go .direct to a storage bay and chute, which are provided in the dispatch section adjacent to those used for steel.

In the case of phosphor-bronze, the same methods are employed as for steel swarf, the tippers being

:painted yellew for :uncontaminated .metal and buff for mixtures such as .pbosphor-browe and east ion or • steel. As certain bronze components pass tbrong,h finiShing processes after being Shrunk on to iron or steel centres, some mixing is inevitable, but a magnetic plant :removes steel and iron from this grade.

Where particular grades of cutting Itihricant are used exclitislwely in certain sections of the factory, small 'Whizzers " are installed for reclaiming oil in the actual machining department. -These special plants are, therefore, confined to that part of the -works where the oils in .queslion are employed.