The First Austin Lorry.

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

First-published Particulars of a Remarkable Design of 30-cwt. Chassis,

We have, for quite a number of years now learned to look for originality and boldness of design from Mr. Herbert Austin in whatever branch of construction he interests himself. He has seldom allowed his undoubted creative genius to be fettered by conventional methods of construction. It is for this reason that we are always pleased to have an invitation from him to inspect any new model which may have been produced from his shops.

Quite a Dtparture.

It is a long while since Mr. Austin gave much serious attention to the production of commercial motors of any considerable load capacity. As a matter of fact, we think his only incursion into the industrial field since he has been building up, in so remarkable a manner, the fortunes of the Austin Motor Co., Ltd., at Northfield, Birmingham, has consisted of the production of a natty little cab chassis, which, however, did not quite satisfy the ideas of the Scotland Yard authorities. Nevertheless, the same model has done excellent service as a small van and as a private landaulette. It may be remembered that the driver is seated centrally, as regards that chassis, iannediately over the engine, and we think we are correct in assuming that the smaller model, which will be shown on Stand No. 1, at the City Hall, Manchester, will be of that type.

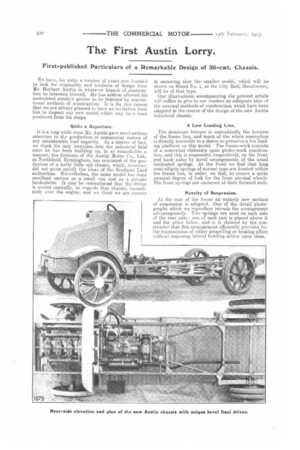

Our illustrations accompanying the present article will suffice to give to our readers an adequate idea of the unusual methods of construction which have been adopted in the course of the design of the new Austin industrial chassis.

A Low Loading Line.

The dominant feature is undoubtedly the lowness of the,frame line, and much of the whole conception is directly traceable to a desire to preserve a, low loading platform on this model. The trame-work consists of a somewhat elaborate open girder-work construction, and this is suspended, respectively, on the front and back axles by novel arrangements of the usual laminated springs. At the front we find that long semi-elliptic spring's of normal type are located within the frame line, in order, we find, to ensure a quite unusual degree of lock for the front pivoted wheels. The front springs are anchored at their forward ends.

Novelty of Suspension.

At the rear of the frame an entirely new method of suspension is adopted. One of the detail photographs which we reproduce reveals the arrangement advantageously. Two springs are used on each side of the rear axle ; one of each pair is placed above it and the other below, and it is claimed by the constructor that this arrangement efficiently provides for the transmission of either propelling or braking effort without imposing lateral bending action upon them. Large Leek and Easy Steering.

We referred just now to the provision which has been made to ensure that this machine should have the maximum of lock. Care has also been taken to secure the greatest. possible facility of steerage. For that purpose, special east-steel wheels have been devised, and these are dished in such a manner that the pivots are located directly over ths points of contact between tires and road.

Another feature of the wheel design is the entire absence of protruding hub, a characteristic which will be much appreciated by those who have not hesitated to launch criticisms in this respect at some of the models which are much in use to-day. Quite a considerable proportion of the collisions in thick traffic, in which London motorbuses are involved, are

due to the striking, by some passing object, of protruding front hub caps. All four road wheels on the Austin 12j-tanner are of east-steel, and the front one

riveted on to a, flanged spindle of case-hardened nickel steel, which runs in phosphor bronze bushes tarried in the swivel heads. The rear wheels are bushed, and run on the axle tube, which is specially ground for the purpose.

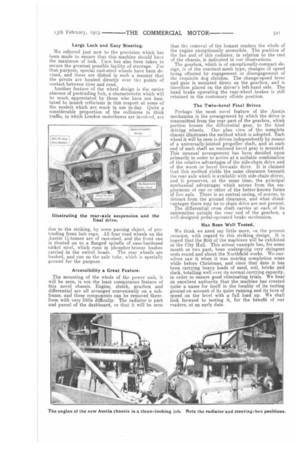

Accessibility a Great Feature.

The mounting of the whole of the power unit, it will be seen, is not the least conspicuous feature of this novel chassis. Engine, clutch, gearbox and differential are all arranged conveniently on a. subframe, and these components can be removed therefrom with very little difficulty. The radiator is part and parcel of the dashboard, so that it will be seen that the removal of the bonnet renders the whole of the engine exceptionally accessible. The position of the fan and of this radiator, in relation to the rest of the chassis, is indicated in our illustrations.

The gearbox, which is of exceptionally-compact design, is of the constant-mesh type, changes of speed being effected by engagement or disengagement of the requisite dog clutches. The change-speed lever and gate is mounted direct on the gearbox, and is therefore placed on the driver's left-hand side. The hand brake operating the rear-wheel brakes is still retained in the customary offside position.

The Twin-bevel Final Drives.

Perhaps the most novel feature of the Austin mechanism is the arrangement by which the drive is transmitted from the rear part of the gearbox, which portion houses the differential gear, to the hind driving wheels. Our plan view of the complete chassis illustrates the method which is adopted. .P:sich wheel it will be seen is driven independently by means of a universally-jointed propeller shaft, and at each end of each shaft an enclosed bevel gear is mounted. This unusual arrangement has been decided upon primarily in order to arrive at a suitable combination of the relative advantages of the side-chain drive and of the worm or bevel live-axle drive. It is claimed that this method yields the same clearance beneath the rear axle which is available with side-chain drives, and it preserves, at the same time, the principal mechanical advantages which accrue from the employment of one or other of the better-known forms of live axle. There is no central casing, of course, to detract from the ground clearance, and what disadvantages there may be to chain drive are not present.

The differential cross chaft carries at each of its extremities outside the rear end of the gearbox, a well-designed pedal-operated brake mechanism.

Has Been Well Tested.

We think we need say little more, on the present occasion, with regard to this striking design. It is hoped that the first of the machines will be exhibited at the City Hall. This actual example has, for some month or two past, been undergoing very stringent tests round and about the Northfield works. We ourselves saw it when it was nearing completion some while before Christmas, and since that date it has been carrying heavy loads of sand, soil, bricks and slack, totalling well over its normal carrying capacity, in order to ensure good eliminating trials. We hear on excellent authority that the machine has created quite a name for itself in the locality of its testing ground on account of its quiet running and its turn of speed on the level with a full load. up. We shall look forward to testing it, for the benefit of our readers, at an early date.