THE UPKEEP OF STEAM WAGONS.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

No. 4.—Regulation of Power—Pump and Injector Merits—Steering and Brake Control—Lubrication Hints.

Dealing with the regulation of engine power, two opinions am held with regard to the relative use of the stop Valve and the reversing lever. Some drivers believe in regulating the power entirely by the stop yalve, Le., deereasing the pressure of the steam slipplied to the cylinders by throttling it, -and always working with the reversing lever in full-gear position. Others hold the opinion that it is. better to notch up the reversing lever and work with the stop valve open as much as possible. The idea of the latter is to increase the economy of the engine by cutting off the steam earlier in the cylinders and using it more expansively, keeping the initial pressure the same. This principle is quite right for an engine running at slow speeds, but for a high-speed engine it does not hold good.

Mr. Viriilans, in his classical experiments on steam engines, proved that it was just as economical to govern a high-speed engine by throttling the Steam supply as it was. to cut off earlier in the cylinders. That is why all the high-speed engines used for driving dynamos were fitted with governors acting on a throttling stop valve, whereas slow-speed engines were fitted with crankshaft governors or Corliss trip gears, which automatically varied the cut-off.

As the steam-wagon engine is essentially a high• speed one, it follows, therefore, that the throttling method is the hest; in fact, some makers only put three notches in the reversing lever guard, full gear forward, --full gear backward and mid gear. It must not be thought that because the steam is throttled down to a lower pressure when using this method that the value of using high-pressure steam is lost. The economy is chiefly in the boiler efficiency, which in this case is not affected.

Another disadvantage of notching upis the uneven . wear of the slide valve faces clue to shortening the travel ; it will tend to make the cylinder faces wear hollow, and thereby cause the valves to leak. A feature of the reversing gear, however, which must not be forgotten, is that the engine will.always stop when the reversing lever is put ha the middle notch; this is very useful should the stop valve leak. It is a wise plan always to put the lever in the middle notch whenever the engine is left standing under steam. Only recently a case tame under the writer's notice, where a traction engine commenced to run after the driver had left it, and did considerable damage, due to the stop valve leaking. A method of temporarily increasing the power of the engine is adopted by fitting a. double high-pressure steam gear to the cylinders. The action of this is to admit high-pressure steam straight from the

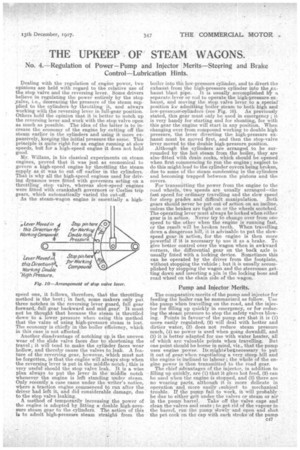

boiler into the low-pressure cylinder, and to divert the exhaust from the high-pressure cylinder into the exhaust blast pipe. It is usually accomplished k6 a separate lever or rod to operate the high-pressure exhauet, and moving the stop valve lever to a special position Sec admitting boiler steam to both high and low-press/met-cylinders (see Fig. le). As previously stated, this gear must only be used in emergency ; it is very handy for starting and for shunting, for with this gear the engine will start in any position. When changing over from compound working to double high pressure, the lever diverting they high-pressure exhaust must be moved first, and then the stop-valve lever moved to the double high-pressure position.

Although the cylinders are arranged to be surrounded by the hot steam from the boiler, they are also-fitted with drain cocks, which should be opened when first commencing to run the engine; neglect to do this might lead to the cylinder covers being broken, due to some of the steam condensing in the cylinders and becoming trapped between the pistons and the covers.

For transmitting the power from the engine to the road wheels, two speeds are usually arranged—the fast speed for ordinary travelling and the slow speed for steep grades and difficult :manipulation. Both gears should never be put out of action on an incline, unless the brakes are tight on or the wheels scotched. The operating lever mugt always be locked when either gear is in action. Never try to change over from one speed to the other when the engine is running fast, or the result will he broken teeth. When travelling down a dangerous hill, it is advisable to put the slowspeed gear in action, for the engine is then more powerful if it is necessary to use it as a brake. To give better control over the wagon when in awkward corners, the differential gear on the bacle axle is usually fitted with a locking device. Sometimes this can be operated by the driver from the footplate, without stopping the vehicle ; but it is usually accomplished by stoppmg the wagon and the steersman getting down and inserting a pin in the locking boss and road wheel on the chain side of the wagon.

Pump and Injector Merits.

The comparative merits of the pump and injector for feeding the boiler can be summarized as follow. Use the pump when travelling on the road, and the injector for filling up quickly in emergency, or for reducing the steam pressure to stop the safety valves blowing. Points in favour-of the pump are that it is (1) more easily regulated; (2) will deal with hotter and dirtier water, (3) does not reduce steam pressure much, (4) no power is used when going downhill, and (5) it is better adapted for use with water heater, all of which are valuable points when travelling. But one point should be borne in mind, viz., that the pump uses engine power. Itemightibeenecessary to putit out of geaae when negotiating a very steep hill and the engine is inclined to labour ; the whole of the engine power is then transmitted to the road gear.

The chief advantages of the injector, in addition to filling uP quickly, are (1) that it gives hot feed, (2) can he used when the engine is stopped, and (3) there are no wearing parts, although it is more delicate in operation and more easily subject to mechanical trouble. If the pump fail to work, it will probably be due to either grit under the valves or steam or air in the pump barrel. Take off the valve caps and dean the valves and seats ; to get rid of the vapour inthe barrel, run the pump ,qowly and open and shut the pet cock on the cap with each stroke of the pump

until the vapour is all driven out. If the injector gets • hot, it will not work ;. cool it by pouring cold water Over it. Other defects and their remedies, of pumps and injectors, will be'described later.

Steering and Brake Control.

The steering wheel is sometimes placed on the near side of the wagon and sometimes on the off side ; opinions vary as to which is the better side. For town work the off side is better, as the chief point to watch is to clear opposite traffic; on the other hand, the near side is better for country work, in order to keep clear of ditches and other obstacles at the road sides. To steer the wagon to the right, the top of the hand wheel should turn to the right, and vice versa for, the left. The steerage should be quick in action and easily operated, especially on rubber-tyred wagons.

For proper control of a wagon the brake gear should be of the type whiCh acts on both hind wheels direct. One brake is then only necessary, as reversing the engine fulfils the legal requirements according to the "Motor Cars Amendment Order, 1912." The brake should be of the type which is operated by a lever ; the hand wheel and screw type is too slow and inconvenient. For town work it s an advantage if a light foot brake operating on the flywheel is fitted ; this is very handy for manoeuvring in busy traffic, where sudden stops are sometimes necessary, and the wagon is usually moving slowly.

Attention to Lubrication.

The lubrication of a steam wagon: is a most vital point. The fundamental principle is to make the machine go more easily) at less cost and with less wear and trouble, i.e., to increase the mechanical efficiency and utilize the maximum available power of the engine. Unfortunately, this feature has never been properly studied in the design of steam wagons, and the use of the driver's oil feeder is too often necessary, with the result that the greater part of that oil is splashed about the vehicle and driver,, giving both a very untidy appearance. Good oil should be used, especially for the cylinders and valves, and the oiling should be dime in a systematic manner. . For the cylindera use a good thick, mineral oil such as Willcox's " 51 " grade, or vacuum ." Hecla B," which will not carbonize or become gummy. The motion work reqUires a thinner oil, for the lubricators. are mostly, of the wick syphon type, vacuum " HH..Special " being a good brand for this purpose. If the engine is en

closed with splash lubrication, a thicker oil should be used, by mixing an equal quantity of cylinder oil with it ; this will also be found suitable for enclosed differential gears.

c4a

For the axles, grease will be found to give very good results, unless an oil pad is used, when a thinner oil, such its that used for the motion work, will be necess sary. Most lubricators of a steam wagon require attention and refilling daily, especially the cylinder oil pump, which is now universally fitted. This pump should never be allowed to run dry, or it will be difficult to set, it in. operation again • it should be watched occasionally to see that it is w'O'rking properly. If the pump is not working satisfactorily, take oat and clean the small check valve on top of the cylinder arid the small vaIve 'at, the bottom of the sight-feed glass. Never pour oil into the pump unless the wire gauze strainer is in position ; grit in the oil is sure to cause

trouble. In cold weather the oil in the pump should be warmed up before commencing to run the engine ; a steam pipe for this purpose is usually fitted. The other parts requiring daily atlention are : crank bearings, connecting-rod bearings, crossheads and guide bars, link motion, change-speed gear, bridles, eccentric Straps, steering joints. The parts which may be attended to NVeekly are as follow: differential gear, spring., slides, axle boxes, front wheels, forecarria,ge turntable.

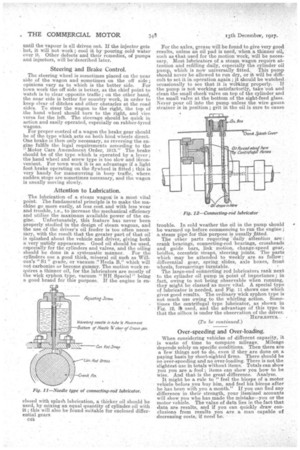

The large-end connecting' rod lubricators rank next to the cylinder oil pump in point of importance ; in fact, owing to not being observable when running, they might be classed-as more vital. A special type of lubricator is needed, and Fig. ii shows one which gives good results. The ordinary wick syphon type is not much use owing to the whirling action. Sometimes the centrifugal type lubricator, as shown in Fig. 12, it used, and the advantage of this type is that the oilbox is under the observation of the driver. REPEL:MILTS(To be continued.)

Over-speeding and Over-loading.

When considering vehicles of different capacity, it is waste of time to compare mileage. Mileage depends solely on specific conditions. Then there are a few things not to do, even if they are done an a paying basis by short-sighted firms. There should be no over-speeding and no over-loading. There is not the slightest use in totals without items. Totals can show you you are a fool ; items can show you how to be wise. And that is the great difference. Analyse.

It might be a rule to " feel the biceps of motor vehicle before you buy him, and feel his biceps after be has been with you a month." If you can find any difference in their strength, your itemized accounts will show you who has made the mistake—you or themotor vehicle. The value of data lies in the fact that data are results, and if you can. quickly draw conclusions from results you are a man capable of decreasing costs, if need be.