Mercedes-Benz battery bus

Page 57

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

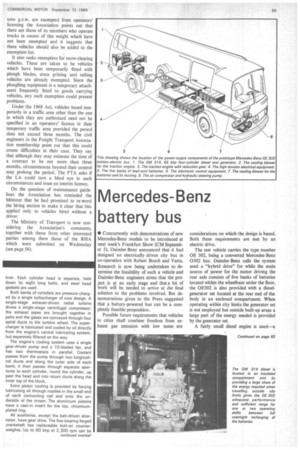

• Concurrently with demonstrations of new Mercedes-Benz models to be introduced at next week's Frankfurt Show (CM September 5), Daimler-Benz announced that it had designed an electrically driven city bus in co-operation with Robert Bosch and Varta. Research is now being undertaken to determine the feasibility of such a vehicle and Daimler-Benz engineers stress that the project is at an early stage and that a lot of work will be needed to arrive at Lhe final solution to the problems involved. But demonstrations given to the Press suggested that a battery-powered bus can he a completely feasible proposition.

Possible future requirements that vehicles in cities shall combine freedom from exhaust gas emission with low noise are considerations on which the design is based. Both these requirements are met by an electric drive.

The test vehicle carries the type number OE 302, being a converted Mercedes-Benz 0302 bus. Daimler Benz calls the system used a "hybrid drive" for while the main source of power for the motor driving the rear axle consists of five banks of batteries located within the wheelbase under the floor, the 0E302 is also provided with a dieselgenerator set located at the rear end of the body in an enclosed compartment. When operating within city limits the generator set is not employed but outside built-up areas a large part of the energy needed is provided by the generator set.

A fairly small diesel engine is used—a

3.8 litre four-cylinder unit giving 65 bhp at 2,200 rpm—and because it will always run in the most favourable performance range at constant speed there is optimum fuel econo

my and reduced exhaust gas and noise. The DC motor driving the wheels is employed for initial braking when it acts as a generator and supplies energy for the batteries and this, in conjunction with taking energy from the generator unit in less populated urban areas when the batteries are also recharged, will allow the OE 302 to operate a full shift or possibly two shifts before the batteries have to be completely recharged overnight.

The OE 302 has a gross weight of 16 tons and carries 3.5 tons of batteries but with the generator set and electrical equipment weighing about the same as a normal engine and gearbox, unladen weight is kept to about 12 tons so allowing 66 passengers to be catered for within a gross weight of 16 tons.

The driving motor delivers 115 kW between 1,600 and 4,800 rpm which is equal to a constant output of 156 bhp between these speeds. Output can be increased for short periods at speeds below 1,600 rpm to a peak of 204 bhp at 1,300 rpm. This means

that while gradients of I in 9 can be tackled under normal driving conditions, climbing ability can be increased to 1 in 6.5 for short periods. Maximum speed on a level surface is 43.5 mph and while acceleration performance is equivalent to that of a dieselengined bus at normal speeds, starting acceleration has been limited to 3.28ft /sec2 to safeguard any standing passengers.

Electronic controls are located between the batteries in the centre of the vehicle and are operated through conventional accelerator and brake pedals. The batteries are cooled by an electrically driven blower at the front of the vehicle and this motor also drives an air compressor for the main brakes, air suspension and door operation and an hydraulic pump for the power-steering system.

The demonstrations of the OE 302 showed the character to be similar to that of a trolleybus with good acceleration and quietness; the diesel-generator set is well insulated from the body and most of what noise there was came from the electrically driven blower installation at the front end.