Simple or Sophisticated.

Page 108

Page 109

Page 110

Page 112

Page 113

If you've noticed an error in this article please click here to report it so we can fix it.

While the majority of semi-trailer users want a running gear/suspension system t a is simple, cheap and proof against continued abuse, advanced systems are available that cater for the more discerning operator

Is the semi-trailer the most neglected vehicle on British roads? This is certainly the view of technicians at Rubery Owen Rockwell Ltd., Darlaston, Staffs, who maintain that, for this reason, it should ideally be designed to continue running satisfactorily for the longest possible time even under conditions of maximum abuse. And they also make the point that sophisticated running gear and suspension systems, notably air suspensions, are more in favour on the Continent and that only a minority of UK operators are willing to pay for sophistication.

The Ruben? Owen people, obviously having their well-known M Series suspension in mind, also emphasize that an established running gear needs continuous development in the interest of progressive refinement, and that this development must be backed by up-to-date research facilities. This important aspect is frequently overlooked by the advocates of new types of equipment. There have been very few revolutionary changes in the history of the motor vehicle over the past 50 years. The outstanding progress made has mainly been derived from continuous development of established designs.

Simplicity and constant development have made the M Series suspension hard to beat; it is easily maintained, robust and light and is designed for easy fitting to conventional frame members. Moreover, it is fitted to a very large number of semi-trailers and its design is commonly regarded as a standard with which other and more sophisticated systems can be compared. And it can be supplied with single taper-leaf springs produced to Rockwell standards by the Bramber Engineering Co. Ltd., kits being available for the conversion of existing multi-leaf suspensions.

Basically, each unit of an M Series suspension comprises a slipper-ended spring that bears on variable-rate pads, the under-slung axle bracket being linked to a chassis bracket by an adjustable rubber-bushed brake-torque arm. In tandem-axle applications, the inner slipper ends of the two springs bear on the pads of a rocking-beam equalizer. In both cases, deflection of the spring under load shortens its effective length, and the stiffness of the spring is increased approximately in proportion to the load. No lubrication is necessary.

A Type M22 22,000lb suspension weighs from 440Ib to 483Ib according to the frame height, while the weight variation in the case of the M44 tandem-axle 44,000lb suspension is from 880Ib to 9241b. Multi-leaf springs with 9 or 10 leaves are available.

Double life

Bramber Engineering say that the laboratory fatigue life required of a taper-leaf spring is double that of a multi-leaf spring and that this has been obtained. While single-leaf springs would normally be fitted to the suspension of a semi-trailer, the driving axle of a tractive unit would be equipped with a system having two-leaf springs.

As well as saving weight the springs are claimed to have a longer service life, to give a better ride because inter-leaf friction is eliminated and to enable maintenance to be reduced because there is no fretting or corrosion. Weight savings cited by the company include a reduction from 83Ib to 38Ib if a single spring is used in place of an 11-leaf spring having a capacity of 10,5001b.

Self-levelling air suspension has a low spring rate compared with a laminated-spring type and the rate varies strictly in accordance with axle loading. These are outstanding advantages in the case of a vehicle that operates with big load variations and carries a fragile load or body susceptible to damage when subjected to high-frequency vibration and bump shocks over extended periods. Many semi-trailers are in this category, including large tankers and vans, which may have five times the empty axle loading when laden.

Unfortunately a low spring rate gives a low roll resistance and this can be a big disadvantage when a vehicle carrying a high load is negotiating a curve or S bend. The spring base of an air system is normally somewhat less than the base of a leaf-spring system and this increases the roll tendency.

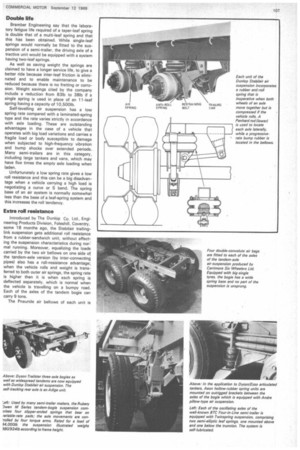

Extra roll resistance

Introduced by The Dunlop Co. Ltd.. Engineering Products Division, Foleshill, Coventry, some 18 months ago, the Stabilair trailinglink suspension gets additional roll resistance from a rubber-sandwich unit, without affecting the suspension characteristics during nor:mal running. Moreover, equalizing the loads carried by the two air bellows on one side of the tandem-axle version Iby inter-connecting pipes} also has a roll-resistance advantage when the vehicle rolls and weight is transferred to both outer air springs, the spring rate is higher than it is when each spring is deflected separately, which is normal when the vehicle is travelling on a bumpy road. Each of the axles of the tandem bogie can carry 9 tons.

The Pneuride air bellows of each unit is mounted directly above the axle, which is located by the trailing link and a Panhard rod. The triangular trailing link has an extension at its lower end that bears on a Metalstik rubber spring, the opposite end of which abuts on a bracket underslung from the axle.

The link and bracket are connected by an adjustable bolt which can be used to preload the spring by a predetermined amount. Bump rubbers in the bellows are of the progressive type, capable of supporting the entire load; rebound is controlled by inclined telescopic dampers. Levelling valves control the bellows of the front springs of the tandem-axle suspension. Also of importance in the matter of roll resistance, the roll centre of each axle corresponds with the inner pivot of the Panhard rod, which is higher than that of a typical leaf-spring suspension. A high roll centre is favourable to roll resistance.

All the bushes are of rubber, so no lubrication is needed. While use of a Stabilair tandem-axle suspension increases the cost of the vehicle by some £150, around 100lb weight can be saved.

Incorporated in a number of suspension! axle, assemblies produced by trailer makers, Dunlop Pneuride air bellows are offered in twoand three-convolute form in nine sizes with diameters ranging from Sin. to i4-in. and load ratings of 1 ton to 4 tons, while accessories include a levelling valve. In a typical load /deflection curve, an increase in load from 2,6001b to 3,600lb (1,0001b) produces a deflection of lin., while an increase from 5,000lb to 6,000lb deflects the spring about 0.65in. The spring rate increases during a bump because deflection expands the spring to give a greater effective area. Larger air tanks can be fitted in a system to increase the total volume of air. This gives a lower spring rate, as may be required to provide a particularly soft ride.

An auxiliary suspension system that can be incorporated in an existing suspension (or used as original equipment) has obvious potential merits in the case of applications to a vehicle with a high centre of gravity that tends to be unstable on curves. Aeon Products (London) Ltd., 11-21 Northdown Street, London Ni, produced a special hollcw rubber-spring system in conjunction with the Esso and Dyson companies for application to a Leyland Freightmaster /Dyson semi-trailer tanker outfit to reduce roll and improve stability on curves; a substantial number of 32ton-gross, 7,000 gal outfits of this type are now being operated by Esso for deliveries of petroleum products.

The tandem bogie of the semi-trailer is equipped with Andre pillow-type air bags between the tanker sub-frame and the axle beams, and the Aeon units are mounted on brackets located between the axles and outrigged from the frame. In this position, they increase the effective spring base of the conbined air/rubber suspension systems as well as the rate and thus improve the roll resistance of the suspension and the natural roll .frequency of the sprung mass. Mounted on a vertical tube, the two Aeon springs are so arranged that the upper double-convolute spring resists roll and the lower singleconvolute spring controls rebound. The load. deflection rate of the springs increases with load and this raises the roll frequency of the sprung mass, which is especially useful in reducing roll-back amplitude on a "second curve". Two Aeon springs are also fitted on each side of the tractive unit frame spanning the driving axle, in which position they act as progressive-rate bump rubbers and cater for high load transfer to the outer wheels on curves.

Overcoming deficiencies

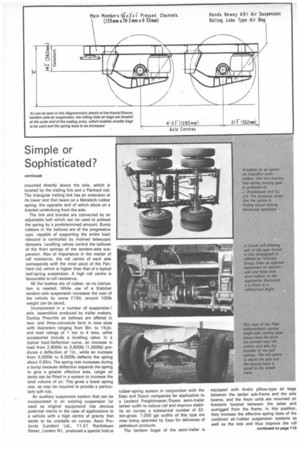

It is stated by Hands Trailers Ltd. that the Hands /Neway ARI tandem-axle air suspension was developed to overcome deficiencies of typical air systems that had persisted over more than 10 years, including poor roll resistance, inefficient levelling-valve characteristics, short air-bag life and so on. Based on trailing arms with rolling-lobe air bags, mounted behind the overslung axle, the ARI system provides a relatively low riding height and the axle acts as an anti-roll torsion bar. Moreover, the roll centre is at axle height (the roll centre of independent trailing-arm suspension is at ground level) and locating the pivots of the arms on the same level as the axle reduces "roll-steer" to a minimum. Because the bags are mounted behind the axle, they carry less of the load (because the arm acts as a lever) than they would if they were positioned above the axle, and smaller bags can be employed. And this enables the spring base to be increased. Rolling-lobe air bags can be fitted having a periodicity as low as 87 cycles /min., which is of particular advantage if fragile goods are being carried. A tandemaxle system complete with sub-frame, brake gear and 16.5-22.5 super-single tyres weighs 1 ton 15cwt.. the weight being increased to 1 ton 18cwt. if twinned wheels are fitted carrying 10.00-22.5 covers.

For jams and jellies

A trailing-arm type of independent air suspension is produced by Scammell Lorries Ltd. for application to semi-trailers that have to transport easily damaged goods, and the Schweppes company recently specified the suspension for a Scammell /Duramin Silverline 30-ton-gross boxyan employed to carry jams, jellies and canned goods. Each of the four wheels is mounted on a separate arm and springing is provided by a two-convolute air bellows. It is stated that roll is "progressively resisted" by the air springs.

Catering for a multitude of tastes (or requirements) the York Trailer Co. Ltd. of Corby, Northants., offers a standard type of tandem-axle bogie with slipper-ended springs and torque arms (the TS), a non-load-transfer version of this type of suspension (the TA), a non-hop tandem known as the Long-Rocker, the Airpoise tandem with pillow air suspension, a four-wheels-in-line running gear (the Transfour) and a single-axle running gear of the slipper-spring-and-torque arm type which is also available (if an extra soft ride is required) fitted with Laminaire suspension. York say that a big feature of all the company's running gears is that they provide precise axle alignment, which is a most important characteristic.

Being almost horizontal, the torque arms of the TA suspension are so arranged relative to the rocking beams that they act as torque arresters and balance out brake-torque reaction. The operating range of pressures of the Airpoise suspension is from /12 psi. unladen to 47/53 psi. laden, air pressure being automatically increased in the pillow on the outer side when cornering to give a higher roll resistance.

The DNR tandem-axle dual-non-reactive system, produced by R. A. Dyson and Co. Ltd., is equipped with rubber-bushed radius arms (that absorb brake torque) in addition to duplicated torque-cancelling systems, the object of the exercise being to eliminate chatter as well as wheel hop. This system is available in place of a Rubery Owen suspension and if it is applied to a semi-trailer destined to carry a high load it is equipped with special double acting anti-roll bars.

Whereas the Dyson Aeroride tandem-axle suspension is based on dual-cell full-length air pillows, widespread tandems and three-axle bogies are equipped with a Dunlop Stabilair system, the latest addition to the range being a bogie with a 79in. spread that has an Adige self-tracking rear axle and is particularly suitable for 32-ton-gross outfits.

An Adige rear axle is also a feature of the company's Trailsteer three-axle bogie which is available with a six-spring rocker-arm type of non-reactive suspension based on leaf springs or on a Dyson air spring system in which 12in. double-convolute bellows are mounted on flexible multi-leaf-spring trailing arms. Single 10.00-20 16 ply tyres are mounted on heavy-duty welded wheels.

Payload advantage

Of the advantages offered by an oscillating in-line axle, the one that has the most topical interest is the increased roll resistance it offers by virtue of its relatively wide spring base. And the 11-ton loading now allowed by the regulations provides for a payload advantage when the trailer is coupled to a twinsteer tractive unit for operation at 28 tons gross that may equal that of a tandem-axle 30-ton-gross outfit. And the absence of tyre scrub should give a substantially better tyre life.

Each of the oscillating axles of the Fourin-Line system, produced by the British Trailer Co. Ltd., is equipped with ETC Twinspring suspension comprising two semi-elliptic leaf springs, one above and one below the axle, all the equipment being self-lubricated. Twinspring suspension is also applied to the corn

pany's single-axle and tandem-bogie running gear, a special advantage of the suspension for the latter application being that brake torque is absorbed without radius arms. The leaf springs of the tandem are inverted.

Independent suspension

While the BTC Four-in-Line system may be regarded as a special form of independent suspension, the coil-spring swing-axle type of independent suspension produced by Peak Trailers Ltd. is conventional in that the spring base is equal to the wheel track. In both cases a relatively high roll centre is provided that increases resistance to roll.

The widely separated bearings of the Peak suspension spread the braking-torque load over a wide area and in the case of the tandem version of the suspension varying the spread of the axles to suit individual applications is simplified by the use of a tension rod to link the compensating mechanisms. Mounting the arms on pivots near the centre of the vehicle reduces camber change (and tyre scrub) to a minimum.

The possibility of rubber suspension coming into its own cannot be discounted. Produced by North Derbyshire Engineering Co. Ltd., Darley Dale, Matlock, Derbyshire, Norde rubber suspension has been successfully applied to heavy articulated vehicles including tankers. Based on Metalstik multi-sandwich rubber springs the Norde system provides favourable characteristics by virtue of the fact that the rubber is loaded in shear as well as compression. The Norde suspension has found particular favour amongst tanker operators because of its high roll resistance and long maintenance-free life.