A New Light 6 x 6

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

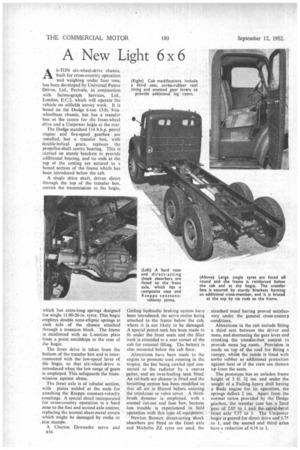

A6-TON six-wheel-drive chassis, built for cross-country operation and weighing under four tons, has been developed by Universal Power Drives, Ltd., Perivale, in conjunction with Seismograph Services, Ltd., London, E.C.2, which will operate the vehicle on oilfields survey work. It is based on the Dodge 6-ton 13-ft. 9-inwheelbase chassis, but has a transfer box at the centre for the front-wheel drive and a Unipower bogie at the rear.

The Dodge standard 114 b.h.p. petrol engine and five-speed gearbox are installed, but a transfer box, with double-helical gears, replaces the propeller-shaft centre bearing. This is carried on sturdy brackets to provide additional bracing, and tic rods at the top of the casting are secured to a boxed section of the frame which has been introduced below the cab.

A single drive shaft,. driven direct through the top of the transfer box, carries the transmission to the bogie, which has extra-long springs designed for single 11.00-20-in. tyres. This bogie employs double semi-elliptic springs at each side of the chassis attached through a trunnion block. The frame is reinforced with an L-section plate from a point amidships to the rear of the bogie.

The front drive is taken from the bottom of the transfer box and is interconnected with the low-speed lever of the bogie, so that six-wheel-drive is introduced when the low range of gears is employed. This safeguards the transmission against abuse.

The front axle is of tubular section, with plates welded at the ends for attaching the Itzeppa constant-velocity couplings. A special detail incorporated for cross-country operation is a hard nose to the first and second axle centres, replacing the normal sheet-metal covers which might be damaged by rocks or tree stumps.

A Clayton Dewandrc servo and B16

Girling hydraulic braking system have been introduced, the servo motor being attached to the frame below the cab, where it is not likely to be damaged. A special petrol tank has been made to lit under the front seats and the filler neck is extended to a rear corner of the cab for external filling. The battery is also mounted below the cab floor.

Alterations have been made to the engine to promote cool running in the tropics, the fan being cowled and connected to the radiator by a canvas gaiter, and an over-boiling tank fitted. An oil-bath air cleaner is fitted and the breathing system has been modified so that all air is filtered before entering the crankcase or valve cover. A thirdbrush dynamo is employed, with a normal cut-out and fuse box, because less trouble is experienced in field operation with this type of equipment.

Newton Bennett direct-acting Shock absorbers are fitted to the front axle and Michelin ZZ tyres arc used, the standard tread having proved satisfactory under the general cross-country conditions.

Alterations in the cab include fitting a third seat between the driver and mate, and shortening the gear lever and cranking the transfer-box control to provide more leg room. Provision is made on top of the roof for fitting a canopy, whilst the, inside is lined with

sorbo rubber as additional protection against heat or if the crew are thrown up from the seats.

The prototype has an unladen frame height of 3 ft. 3i ins, and under the weight of a Failing heavy drill having a Buda engine for its operation, the springs deflect 2 ins. Apart from the normal ratios provided by the Dodge gearbox, the transfer case has a fixed gear of 2.05 to I and the spiral-bevel front axle $37 to I. The Unipower bogie is geared for direct drive and 1.75 to 1, and the second and third axles have a reduction a 6.14 to 1.