HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle--practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, RCA."

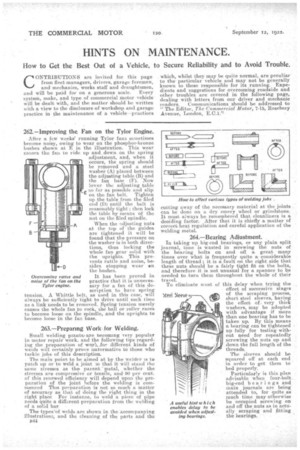

262.—Improving th Fan on the Tylor Engine.

After a few weeks' running Tylor fans sometimes become noisy, owing to wear on the phosphor-bronze bushes shown at E in the illustration. This wear causes the fan to i ide up and, down on the spring adjustment, and, when it occurs, the spring should be removed and a steel washer (A) placed between the adjusting table (B) and the fan base (P). Now lower the adjusting table so far as possible and slip Oil the fan belt. Tighten up the table from the filed end (D) until the belt is reasonably tight ; then lock the table by means of the nut on the filed spindle.

When the adjusting nuts at the top of the guides are tightened it will be found that the pressure on the washer is in both directions, -thus locking the whole fan gear solid with the uprights. This prevents rattle and noise, besides stopping wear en the bushes.

It has been proved in practice that it is unnecessary for a fan of this description to have spring tension. A Whittle belt, as used in this case' will always be sufficiently tight to drive until such time as a link needs to be removed. Spring tension merely causes the whole fan to rock, the ball or roller races to become loose on the spindle, and the uprights to become loose in the fan base.

Overcoming rattle and noise of the fan on the Tylor engine.

263.—Frepanng Work-for Welding.

Small welding plants,. are becoming very popular in motor repair work, and the following tips regarding the preparation of worlices different kinds of welds will certainly prove imtormative to those who tackle jobs of this description,

• The main point to be aimed at by the welder is to patch up or to weld a joint io that it will stand the same stresses as the parent -pieta], whether the stresses are compressive or tensile, and 90 per cent. of this renewed efficiency will depend upon the preparation of the joint before the welding is commenced This preparation is not so much a matter of accuracy as that of doing the right thing in the right place For instance, to weld a piece of pipe needs quite a different preparation from the welding

of a solid bar. • The types'of welds are shown in the accompanying illustrations, and the cleaning of the parts and the B44 cutting away of the necessary material at the joints can be done on a dry emery wheel or grindstone. It must always be remembered that cleanliness is a deciding factor. After that it is chiefly a matter of correct heat regulation and careful application of the welding metal.

264.—Bearing Adjustment. .

In taking up big-end bearings, or any plain split journal, time is wasted in screwing the nuts of the bearing bolts on and off a great many times over what is frequently quite a -considerable length of thread it is a fault on the right side that these nuts should be a fairly tight fit on the bolts, and therefore it is not unusual for a spanner to be needed to .turn them throughout the whole. of their travel.

To eliminate most of this delay when trying the effect of successive stages of the scraping process, short steel sleeves, having the effect of very thick washers, may be adopted with advantage if more than one bearing has to be taken up. By this means a bearing can be tightened up fully for testing without need for repeatedly screwing the nuts up and down the full length of the threads.

The sleeves should be squared off at each end in order to get them to bed properly.

Particularly is this plan advisable when four-bolt big-end bearings and main journals are being attended to, for quite as much time may otherwise be occupied screwing on and off the nuts as in actually scraping and fitting the bearings.