THE KARDELL UTILITY TRACTOR:

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

A Product of American Origin With Several Novel Features Including Quickly Detachable Strakes and an Oil Level Safety Device.

• HE ICARDELL TRACTOR CO., a St. Louis organization, with a capital of $1,000,000, first . came into prominence four years ago with a

tractor called the " 4-in-1," which was designed to do road haulage as a motor truck as well as land haulage as a tractor. Experience with this tractor showed that in practice the theoretical advantages of such a machine are not borne out, and about two anchaehalf years ago the firm set itself out to develop a regular farm tractor on more conventional lines, and, thefirst trials proving successful, a large new factory-was built in St. Louis; and has now been in production for over a year, something like 6,000 machines having, been turned out up to the present time.

This new model has several paints of special inter

est and merit which deserve more than passilw attention. In broad design, it is of the four-wheel type, having 28 in. by 4 in. steering wheels, 48 in. by Bin. drivers, a wheelbase of 118 ins., an outside 'width at the rear wheels of 561 -ins., height to the top of the steeling bracket 5 ft., and a weight of just over

40 cwt.

The engine is a four-eylindered Mid-West with

41 in. cylinders, which' develops sufficient powerfor the machine to handle three 10 in. ploughs under all conditions, land four ploughs under favourable ones. It will turn in a radius of 9 ft., so can be used in small fields without losing ground on the headlands. In ploughing, one wheel is run in the furrow' When the steering becomes automatic. In doing this, it may be noted that the body of the tractor is not racked, as, although Ackermann (automobile type) steering is employed, the front axle is mounted on a control bearing supporting the front end of the machine, which is thus 3-point supported,

and retains a level position, in spite of the 6"ins. or 7 ins, difference between the levels on which the two steering wheels are running when at work with the plough.

Another novel point of considerable merit is found in the engine, a device being fitted in the crankcase by means of which, when the oil gets below the safety level, an electrical cut-out comes into operation which cuts eut the ignition and the engine stops. This should be a very useful fitment, as one of the eemmokest causes of trouble with tractors is neglect of lubrication, with a consequent burning out of engine bearings, which ,mishap, by this device, is effectually prevented.

The carburetter employecPis eitherka,Carter or a Zenith, and a Bennett air-cleaner is installed, which intercepts all dust and prevents it getting into the engine. Ignition is by means of a Dixie or Sinams's magneto, With impulse starter, and a Pierce governor keeps the engine speed down' to 1,000 revolutions, so that the driver has little to worry about sofar as his engine is concerned. The petrol tank carries 12i English gallons of fuel, which is gravity fed to the engine, and the cooling is by centrifugal pump, through a Eureka radiator containing five gallons of water and coaled by a 16 in. 'fan. Lubrication isia combination of force-feed and splash.

As with the Fordson and Austin tractors, the chassis frame is eliminated; the engine crankcase and the gearbox being built to go together and form a complete unit, or body, and in the design of the gearbox another new and very valuable feature is seeia. Cut gears heat treated and running in oil, are entployed, all shafts being mounted on either Hyatt roller or Gurney ball bearings the drive from the engine being through a multiple disc clutch and reduction pinion on to a main 'gear attached to the differential casing and from thence through live axles to the wheels. The especial leature of the gearbox, however, is to be found itt the fact that both the top arid bottom ofthe casing remove bodily, se that at any time any gearwheel or -bearing may be inspected and got at without removing any other part of the mechanism, or taking the whole machine down, as is the case with • some unit-body types of tractors. This feature will be appreciated by all who ha,vo had to do with the running of tractors. , In the speed and :control mechanism, too, originality is found. Two speeds forward are provided, a ploughing speed of 2-i m.p.h. and a road speed. of .31, with a 2 m.p.h. reverse, and the makers argue that in tractor work either one or other of the gears will be used according to the work to be done, and the gears will not requireto be, and should not be changed when working, so they arrange the gear-shifting lever at the side and take it away from contiguity to the driver's seat, this arrangement, it is claimed, preventing the possibility of striping gears by bad changing, as well as simplifying the driving and giving the driver less things to do,. so that he is the better able to concentrate his attention On the work of his implement.

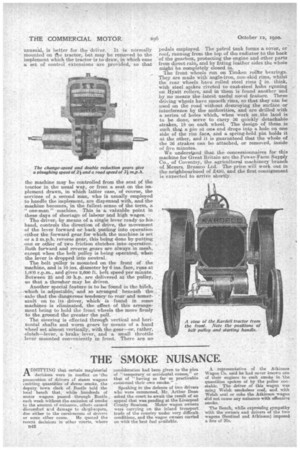

The driver's seat is spring-supported, which, whilst unusu'al, is better for the drit'ier. It is normally mounted an tie tractor, but may be removed to the implement which the tractor is to draw, in which case a set of control extensions are provided, so that the machine may be controlled from the seat of the tractor in the usual way, or from a, seat on the implement drawn, in which latter case, of course, the -services of a, second man, who is usually employed to handle the implement, are dispensed. with, and the machine becomes in. the fullest sense of the term, a " one-man " machine. This is a valuable point hi these days of shortage of labour and high wages.

The driver, by means of a single lever ready to-his. hand, controls the direction of drive, the movement of the lever forward or back putting into operation either the forward gear for which the machine is set or a 2 m.p.h. reverse gear, this being done by putting one or other of two friction clutches into operation. Both forward and reverse gears are always in mesh, 'except when the belt pulley is being operated, when the lever is dropped into neutral.

The belt pulley is mounted on the front of the machine, and is 10 ins. diameter by 6 ins, face, runs at 1,000 r.p.m., and gives 2,600 ft. belt speed per minute. Between 25 and 30 h.p. are delivered at the pulley, so that a thresher May be driven.

Another special feature is to be found in the hifch, ,which is adjustable, and so arranged, beneath the -axle that the dangerous tendency to -rear and somersault on to its driver, which is found in some machines is eliminated, the effect of this arrangement being to hold the front wheels the more firmly to the ground the greater the pull. •

The steering is effected through vertical and horizontal shafts and worm gears by means of a hand wheel set almost vertically, with the gear—or, rather, clutch—lever, a, brake lever, and a small throttle lever mounted conveniently in front. There are no

pedals employed. The petrol tank forms a, cover, or roof, running from the top of the-radiator to the back of the gearbox protecting the engine and other parts from direct rain, and by fitting leather sides the whole might be completely closed in. The front wheels run on Tim-ken rolltr bearings. They are made with angle-iron, non-skid rims, whilst the rear wheels have rolled steel rims ?; in. thick, with steel spikes riveted to east-steel hubs rgnning on Hyatt rollers, and in them is found another and by no means the •latest useful novel feature. These driving wheels have smooth rims, so that they can be used on the road without destroying the surface or interference by the authorities, and are drilled with a• series of holes which, when work on_the land is to be done, serve to carry 36 _quickly detachable strakes, on each wheel. The design of these is such that a pin at one end drops into a. hole on one side of the rim face, and a spring-held pin holds it at the other, and it is guaranteed that the whole of the 36 strakes can be attached, or removed, inside of five minutes.

We understand that the coneessionnaires for this machine for Great Britain are the Power-Farm Supply f Coventry, the agricultural machinery branch of Co.,Messrs. Brame° Ltd. The price will work out in the neighbourhood of £450, and the first consignment is expected to arrive shortly.