TO TIP, OR NO

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

TO TIP that is the question

I T does not seem a long way off when the tipping body was considered in the light of a novelty, whereas to-day it must be deemed to be an absolute essential in certain spheres of haulage work, where the utmost operating economy is desired.

As an aid to the expeditious discharge of a load, there is to-day a wide choice of equipment, from the simplest form of hand-operated screw gear for only end tipping, to the three-way hydraulic triple-ram tipping gear, and examples of these and intermediate types are to be found at the Show at Earls Court.

Moving-floor bodies are in a class by themselves, and two examples are to be seen, both of which are designed only for hand• operation.

Dealing first with tipping gears, there is much to be said for the straightforward simplicity of the handoperated screw type, either for end tipping or for tipping to the sides and the rear. An interesting example of the latter isshown by the Spenborough :Engineering Co., Ltd., Heckmondwike, on Stand 22.

A Three-way Screw Gear.

This gear consists, essentially, of a cross-shaft, from which spur gearwheels convey the power to two bevel wheels having internally screwed threads in their bosses. The tipping-gear screws pass through these bevels, which have rightand left-handed threads respectively.

The upward motion of the screws is conveyed to the body, via rollers running in a suitably shaped track. The direction in which the body tips is governed by the usual arrangement of hinge pins.

Of the hydraulic types of gear shown by this concern, there is the vertical, telescopic end-tipping equipment for power and hand operation, a horizontal end-tipping gear suitable for bodies up to ii ft., and a three-way gear for

power, with an ingenious scissors-type of hand, control.

A feature ofthe Spenborough gears is the equal distribution of the load over the main frame memliers, and it is to. be noted that suitable compensation is made to protect the gear from abnormal stresses when operating -"under adverse conditions, A awash-plate type of pump is employed in the hydraulic tipping gears.

In the Rock hydraulic end; and three-Way tipping gears, shown by the Truck and Tractor Appliance -Co. (Mcr.),. Ltd., Trafford Park, Manchester, on 'Stand 36, we, find the use of a single cylinder and 'ram, the -latter being fitted with a compensating crosshead. from which the forward • movement of the ram is conveyed back to the lifting-arm assembly.

This form of construction provides for a direct lift of the load, with a considerable reduction in the effort required to raise it. These gears are supplied for loads up to 5 tons.

An Unusual Type.

Anthony Hoists, Ltd. (Stand 41), Minerva Road, London, N.W.10, stages an hydraulic cam-type lifting gear designed for loads up to 8 tons and for fitting to a 10-ft. 6-in. body. The special feature of this gear, which has a horizontal cylinder, is that the ram is provided with a crosshead running in guides forming an integral part of the subframe.

The forward motion of this crosshead is conveyed to a two-armed-cam,, which carries the point of lift 9 ins, ahead of the centre of the load, In the Anthony slant-type, with oscillator bar, the ram is carried direct to the body. This concern also features a telescopic, hydraulic-type of tipping gear, which is sold complete with a special all-steel body. Some notable features of Anthony gears are the absence of piping and the provision made to prevent oil leakage.

Two interesting types of vehicle are shown by the Eagle Engineering Co., Ltd., Warwick, on Stand 72, one of which has a moving floor and the other a rear-loading refusecollecting body.

The moving floor is designed for hand operation. and

is shoWi.i. on a 15-ft, by 7-ft. 6-ton trailer body. The endless belt is mounted on a series of ball-bearing rollers, each cross assembly being split up into three sections.

On the refuse-collecting vehicle, both end tipping and compressing are provided, enclosed, vertical, hydraulic gear, catering for the former, and a horizontal, hydraulic rain for the latter. This body is shown mounted on a Thornycroft Sturdy low-loading chassis.

Bromilow and Edwards, Ltd. (Stand 114), Foundry Street, Bolton, the products of which are sold under the trade name B. and E., has a wide range of gears on view, as well as an example of the Principality moving floor. of which it is the sole manufacturer.

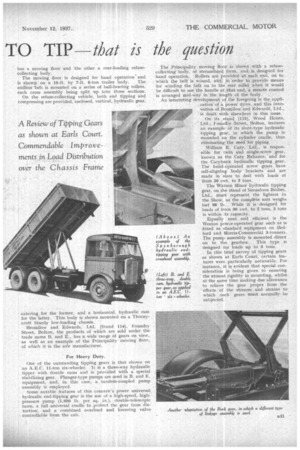

For Heavy Duty.

One of the outstanding tipping gears is that shown on an A.E.C. 11-ton six-wheeler. It is a three-way hydraulic tipper with double rams and is provided with a special stabilizing gear. Plunger-type pumps are used in B. and E. equipment, and, in this case, a tandem-coupled pump assembly is employed.

Some notable features of this concern's power universal hydraulic end-tipping gear is the use of a high-speed, highpressure pump (1,000 lb. per sq. in.), double-telescopic rams, a full •universal cradle to protect the gear from distortion, and a combined overload and lowering valve controllable from the cab. The Principality moving floor is • shown with a refusecollecting body, of streamlined form, and is designed for hand operation. Rollers are provided at each end, on to which the belt is wound, and, in order to proVide means for winding the belt on to the rear roller when it would . be difficult to use the handle at, that end, a remote control is arranged mid-Way in' the length -of the body. An interesting development. of the foregoing is the.application-of a Power drive, and this inno. vation of Brorailow and Edwards. Ltd., is dealt with elsewhere in this issue. On its stand (115), Wood Hoists, Ltd.; Foundry Street, Bolton, features an example of its slant-type" hydraulic tipping gear, in which the pump is mounted on the cylinder cradle, thus eliminating the need for piping.

William E. Cary, Ltd., is responsible for twin and single-screw gear, known as the Cary Reliance,' and for the Carybank hydraulic tipping _gear. The hand-operated screw gears have self-aligning body brackets add are made in -sizes to deal with loadS' of

from 30 cwt. to 5 tons.

. The Watson Minor hydraulic tipping gear, on the stand of Sunsaloon BOdies, Ltd., must represent the lightest in the Show, as the complete unit weighs but 98 lb. While it is designed for loads of from 30 cwt. to 2 tons, 3 tons is within its capacity, .

Equally neat arid efficient. is ,the Weston power-operated gear such as is fitted as standard, eqUipment on Bedford and Morris-Commercial 3-tanners. The pump assembly is mounted direct on to the gearbox. This type is designed for loads up to 5 tons.

In this brief survey of tipping gears as shown at Earls Court, certain features were particularly noticeable. For instance, it is evident that special consideration is being given to ensuring the utmost rigidity in mounting, whilst at the same time making due allowance to relieve the gear proper from the " effects of the stresses and strains to which such gears -must normally be subjected.