SCOPE OF TI UNORTHODOX IN DESIGN

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

ROM the early days the question of engine accessi bility has been to the fore in the thoughts of

designers, but despite the attention that has been paid to positioning the engine in the chassis, the orthodox lay-out with the power unit at the front under the bonnet is still common practice. In only a'few instances has any breakaway been attempted.

At each successive Commercial Motor Show there have been minor alterations to give better accessibility, but in the main manufacturers have never really made a serious effort to overcome the difficulties the operator encounters in maintenance through being unable to inspect and adjust his engine with ease and comfort.

Engine Maintenance Expensive.

Maintenance costs on account of the engine far exceed those involved in the upkeep of other chassis components, and it is obvious that, if engines can be easily inspected and adjusted, much delay and expense will be eliminated by_ nipping troubles in the bud. If a driver, when casually looking over his engine can tighten a nut here and there, as required, he may easily save his employer costly replacements, and, in addition, the loss incurred by holding up the vehicle off the road. Accessibility is undoubtedly halfway to good maintenance.

On several occasions in the past I have reviewed in this paper the pros and cons of various engine positions, and put forward suggestions for schemes which would make for better accessibility, less weight and increased carrying capacity.

1332 It is easy to understand, however, why manufacturers, saddled with an existing range, should hesitate to embark upon the production of machines on these unorthodox lines.

Having recently spent some months in the United States, I am well acquainted with the trend of American design, and have paid particular attention to engine position and the accessibility of this unit. On the passenger vehicle in that country the bonnet is obsolete, and the goods vehicle is follOwing suit. The engine is located either at the rear or amidships, the former position usually being favoured. It seems strange that, while we here have been writing and thinking about it, in America everybody's doing it.

Whilst the rear engine is ideal for bus work, it is, in many cases, unsuitable for goods service, particularly in the case of low-loading and tipping vehicles.

Having studied this problem from all angles, I have arrived at the conclusion that the ideal practice for both types is to install the engine transversely at the front of the chasSis. I propose to describe a layout which appears to comply with all the requirements of accessibility, inspection and maintenance without having recourse to the unorthodox.

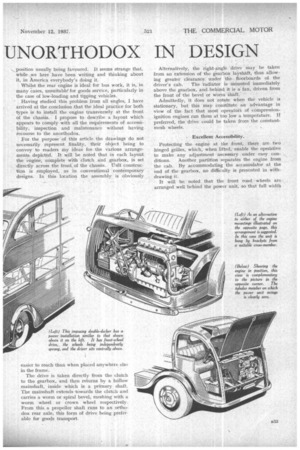

For the purpose of this article the drawings do not necessarily represent finality, their object being to convey to readers my ideas for the various arrangements depicted. It will be noted that in each layout the engine, complete with clutch and gearbox, is set directly across the front of the chassis. Unit construction is employed, as in conventional contemporary designs. In this location the assembly is obviously

easier to reach than when placed anywhere else in the frame.

The drive is taken directly from the clutch to the gearbox, and then returns by a hollow mainshaft, inside which is a primary shaft. The mainshaft extends towards the clutch and carries a worm or spiral bevel, meshing with a worm wheel or crown wheel respectively. From this a propeller shaft runs to an ortho.dox rear axle, this form of drive being preferable for goods transport. Alternatively, the right-angle drive may be taken from an extension of the gearbox layshaft, thus allowing greater clearance under the floorboards of the driver's cab. The radiator is mounted immediately above the gearbox, and-behind it is a fan, driven from the front of the bevel or worm shaft. '

Admittedly, it does not rotate when the vehicle is stationary, but this May constitute anadvantage in view of the fact that most operators of compressionignition engines run them at too low a temperature. If preferred, the drive could be taken from the constantmesh wheels.

Excellent Accessibility.

Protecting the engine at the front, there are two hinged grilles, which, when lifted, enable the operative to make any adjustment necessary under easy conditions. Another partition separates the engine from the cab. By accommodating the accumulator at the end of the gearbox, no difficulty is presented in withdrawing it.

It will be noted that the front road wheels are arranged well behind the power unit, so that full width is available for the accommodation of the engine, gearbox, etc., without interference with the steering lock. The driver can sit centrally, which, I understand, is a position favoured by the Ministry of Transport.

A further advantage of this engine arrangement is :that there is no difficulty about such operations as inspecting and adjusting the crankshaft bearings and gears, or, indeed, about giving the unit a complete overhaul.

One of our drawings shows how the assembly is carried on a tubular cross-member at the front, arms supporting it at the back. By releasing the latter the complete unit can be swung over about the front crossmember, in which position it is ideally situated for the removal of the sump and covers, so that access can be gained to the big-end and main bearings and the underside of the gears. The whole operation can be performed without actually removing the unit from the chassis. In my opinion, this arrangement should reduce overhaul time and maintenance cost considerably.

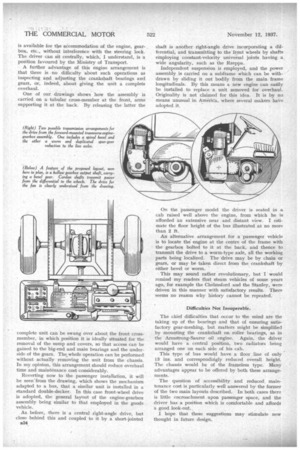

Reverting now to the passenger installation, it will be seen'from the drawing, which shows the mechanism adapted to a bus, that a similar unit is installed in a standard double-decker. In this case front-wheel drive is adopted, the general layout of the engine-gearbox assembly being similar to that employed in the goods vehicle.

As before, there is a central right-angle drive, but close behind this and coupled to it by a short-jointed shaft is another right-angle drive incorporating a differential, and transmitting to the front wheels by shafts employing constant-velocity universal joints having a wide angularity, such as the Rzeppa.

Independent suspension is employed, and the power assembly is carried on a subframe which can be withdrawn by sliding it out bodily from the main frame longitudinals. By this means a new engine can easily be installed to replace a unit removed for overhaul. Originality is not claimed for this idea. It is by no means unusual in America, where several makers have adopted it.

On the passenger model the driver is seated in a cab raised well above the engine, from which he is afforded an extensive near• and distant view. I estimate the floor height of the bus illustrated as no more than 2 ft.

An alternative arrangement for a passenger vehicle is to locate the. engine at the centre of the frame with the gearbox bolted to it at the back, and thence to transmit the drive to a worm-type axle, all the working parts being localized. The -drive may be by chain or gears, or may be taken direct from the crankshaft by either bevel or worm.

This may sound rather revolutionary, but I would remind my readers that steam vehicles of some years ago, for example the Chelmsford and the Stanley, were driven in this manner with satisfactory results. There seems no reason why history cannot be repeated.

Difficulties Not Insuperable.

The chief difficulties that occur to the mind are the taking up of the bearings and that of ensuring satisfactory gear-meshing, but matters might be simplified by mounting the crankshaft on roller bearings, as in the Armstrong-Saurer oil engine. Again, the driver would have a central position, two radiators being arranged one on each side of his cab.

This type of bus would have a floor. line of only 13 ins, and correspondingly reduced overall height. The chassis would be of the frameless type. Many advantages appear to be offered by both these arrangements.

The question of accessibility and reduced maintenance cost is particularly well answered by the former of the two main layouts described.. In both cases there is little encroachment upon passenger space, and the driver has a position which is comfortable and affords a good look-out., I hope that these suggestions may stimulate new thought in future design.