POWER Ft AFRICA

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

...frozA°' rot, BROUGM I ROAD

ib •%.,

5'0

160

THE Kariba hydro-electric project, one of the greatest of this century, is now coming into operation in Central Africa and will be formally opened by Queen Elizabeth the Queen Mother in May. The work has

. . involved a transport contract for £2m. and demonstrated that the greater and more imaginative a• construction job is, the more its progress depends upon successful transport arrangements.

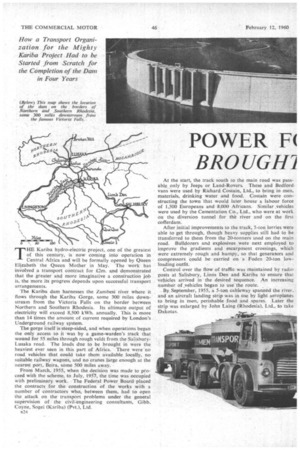

The Kariba dam harnesses the Zambesi .river where it flows through the Kariba Gorge, some 300 miles doWnstream from the Victoria Falls •onthe border between Northern and Southern Rhodesia. Its ultimate output of electricity will exceed 8,500 kWh. annually. This is more than 14 times the amount of current required by London's Underground railway system.

The gorge itself is steep-sided, and when operations began the only access to it 'was by a game-warden's track that wound for 55 miles through rough veldt from the SalisburyLusaka road. The loads due to be brought in were the heaviest ever seen in this part of Africa. There were -no road vehicles that could take them available locally, no suitable railway wagons, and no cranes large enough at the nearest port, Beira, some 500 miles away.

From March, 1955, when the decision was made to proceed with the scheme, to July, 1957, the time was occupied with preliminary work. The Federal Power Board placed the contracts for the construction of the works with a number of contractors Who, between them, had to open the. attack on the transport problems under the general supervision of the civil-engineering consultants, Gibb, Coyne, Sagei (Kariba) (Pvt.), Ltd. n24 At the start, the track south to the main road was passable only by Jeeps or Land-Rovers. These and Bedford• vans were used by Richard Costain, Ltd., to bring in men, materials, drinking water and food. Costain were constructing the town that would later house a labour force of 1,500 Europeans and 8,000 Africans. Similar .vehicles were used by the Cementation Co., Ltd., who were at work on the diversion tunnel for the river and on the first cofferdam.

After initial improvements to the track, 5-ton lorries were able to get through, though heavy supplies still had to be transferred to them from the 20-tonners used on the main road. Bulldozers and explosives were next employed to improve the gradients and escarpment crossings, which were extremely rough and humpy, so that generators and compressors could be carried on a Feder! 20-ton lowloading outfit.

Control over the flow of traffic was maintained by radio . posts at Salisbury, Lions Den and Kariba to ensure that vehicles arrived in the desired sequence. An increasing number of ,vehicles began to use the route.

By.September, 1955, a 5-ton cableway spanned the river, and an aircraft landing strip was in use by light aeroplanes to bring in 'men. perishable food and spares, -Later the strip was enlarged by John Laing (Rhodesia), Ltd., to take Dakotas.

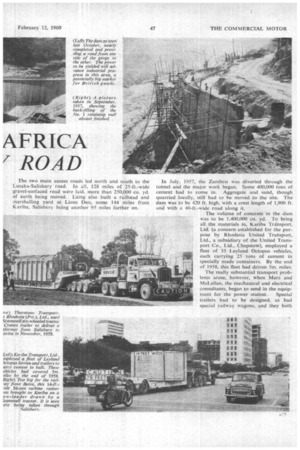

The two main access roads led north and south to the Lusaka-Salisbury road. In all. 128 miles of 25-ft.-wide gravel-surfaced road were laid, more than 250,000 cu. yd. of earth being moved. Laing also built a railhead and marshalling yard at Lions Den, some 144 miles from Kariba. Salisbury being another 95 miles farther on. In July, 1957, the Zambesi was diverted through the tunnel and the major work began. Some 400,000 tons of cement had to come in. Aggregate and sand, though quarried locally, still had to be moved to the site. The dam was to be 420 ft. high, with a crest length of 1,900 ft. and with a 40-ft.-wide road along it. • The volume of concrete in the dam was to be 1,400,000 cu. yd. To bring all the materials in, Kariba Tralnsport, Ltd. (a concern established for the purpose by Rhodesia United Transport, Ltd., a subsidiary of the United Transport Co., Ltd., Chepstow), employed a fleet of 35 Leyland Octopus vehicles, each carrying 25 tons of cement in specially made containers. By the end of 1958, this fleet had driven 5m. miles.

The really substantial transport problems arose, however, when Merz and McLellan, the mechanical and electrical consultants, began to send in the equip ment for the power station. Special trailers had to be designed, as had special railway wagons, and they both had to be made to operate in conjunction with each other.

The heaviest transformer weighed 109 tons. This was too much for any dock crane in South Africa and so the lifting had to be done by the ship's own derricks. Only 11 cargo ships with derricks capable of lifting more than 84 tons were available at this time, so the railway wagons had to be at the dock exactly when required. Head Wrightson and Co., Ltd., produced a well wagon of all-welded construction that had two 10-wheeled bogies, each provided with a compensating springing system ensuring equal loading on all bearing springs. This both conformed with Rbodesian Railways' 3-ft. 6-in, gauge and kept the axle loading below the limit of 15 tons per axle. Sliding tops on the axle boxes allowed for transverse movement of the inner axles on a curve, enabling the wagon to negotiate curves down to a minimum radius of 275 ft.

Transfer from Rail to Road

At Lions Den railhead, Babcock and Wilcox, Ltd., installed a I00-ton Goliath crane for transferring these heavy loads from the rail wagons to the road outfits.

The road problem was even worse than the rail. There was a necessary wheel-loading restriction, because of the unsuitability of even the main roads for such heavy traffic, and the roughness of the terrain through which the access roads passed made a small turning circle essential.

Cranes (Dereham), Ltd., designed a special trailer. It had 32 wheels distributed between two identical bogies, one at each end. Each bogie had four rows of axles with

two rocking axles in each row. The bogies were connected to the frame of the trailer by a turntable, and each bogie could be steered independently, so that the turning_. circle was reduced to a minimum.

The hydraulic suspension system, by regulating the flow of fluid to the cylinder on each axle, enabled the trailer to negotiate uneven ground and rough roads, and clear bumps and low bridges. This type of trailer was required mainly for the transformers and reactors.

Turbine Runners

Loads that could not easily be carried by rail were taken the whole way from Beira to Kariba on smaller lowloaders. They included the drums of 330-kV. cable, which had to be kept upright, and the turbine runners—the largest single pieces of the hydro-electric turbines-14 ft. wide and weighing 56 tons.

The organization of the transport on the Kariba project ranged from killing lions at the outset to setting up a fuelsupply depot and a heavy workshop for the maintenance of what was eventually the largest fleet of heavy-duty vehicles ever assembled in the Federation.

The first electric power will flow from Kariba only 44. years after the first construction contracts were signed. When it does it will be a tribute to the measure of co-operation between the many companies involved, and the perseverance and ingenuity of everyone concerned with the problems of transporting a power station into the heart of Africa.