Long-wheelbase Tipper Conversions

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

THE sight of a short-wheelbase tipper loaded to an excessive height to increase the payload capacity is common, and serves to substantiate the complaint of many hauliers that suitable long-wheelbase tippers are not readily obtainable. Because of their high centre of gravity and the inadequate precautions taken against spillage of material, these overloaded vehicles can be a danger on the road, In service, the rate of tyre wear is often far greater than normal, despite the low cornering speeds to which the vehicles must be restricted to avoid overturning.

The gain in terms of weight carried, when operating a long-wheelbase machine in place of a short-wheelbase tipper depends upon the bulk of the material and the unladen weight of the vehicle. When the load is sand or gravel, the increase in capacity, assuming normal loading, would be about 'U tons; in practice, vehicles on site work are often overloaded and the extra capacity would be greater. For bulky materials, an increase in body length from the standard 8-ft. 3-in. dimension to about 13 ft. may be even more advantageous proportionately.

Frame Failures

Haphazard conversions of longwheelbase chassis to tipper work have often led to early frame failure and other troubles, and even fatal injuries to operators. Vehicles converted by reliable concerns are, however, providing a very valuable service, and according to technicians of Welford Engineering (Oldbury), Ltd., Oldbury, near Birmingham, any long-wheelbase machine can be adapted to tipper use without unduly adding to the weight of the vehicle or risking body instability.

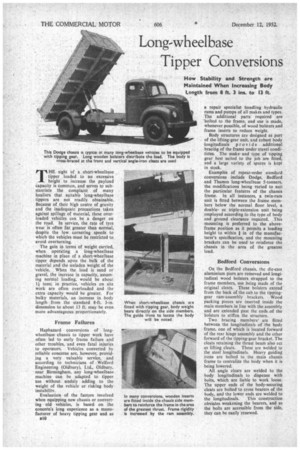

Evaluation of the factors involved when equipping new chassis or converting old vehicles, is based on the concern's long experience as a manufacturer of heavy tipping gear and as a repair specialist handling hydraulic rams and pumps of all makes and types. The additional parts required are bolted to the frame, and use is made, whenever possible, of wood bolsters and frame inserts to reduce weight.

Body structures are designed as part of the lifting-gear unit, and robust body longitudinals provide additional bracing of the frame under travel conditidos. The make, and type of tipping gear best suited to the job are fitted, and a large variety of spares is kept in stock.

Examples of repeat-order standard conversions include Dodge, Bedford and Thames long-wheelbase 5-tonners, the modifications being varied to suit the particular features of the chassis frame. in all instances, a twin-ram unit is fitted between the frame members below the normal floor level, a doubleor triple-extension unit being employed according to the type of body and ground clearance required. This mounting is preferred to the aboveframe position as it permits a loading

height to within in of the manufacturer's specification, and the mounting brackets can be used to reinforce the chassis in the area of the greatest toad.

Bedford Conversions

On the Bedford chassis, the die-cast aluminium piers are removed and longitudinal wood bolsters strapped to the frame rnembers, use being made of the original cleats. These bolsters extend from the back of the cab to the tippinggear ram-assembly brackets. Wood packing pieces are inserted inside the main members in line with the assembly and are extended past the ends of the bolsters to stiffen the structure.

Two bracing membersare fitted between the longitudinals of the body frame, one of which is located forward of the rear hinge assembly and the other forward of the tipping-gear bracket. The cleats retaining the thrust beam also act as lifting cleats. These are welded to the steel longitudinals. Heavy guiding irons are bolted to the main chassis frame to centralize the body when it is being lowered.

All angle cleats are welded to the body longitudinals to dispense with bolts, which are liable to work loose. The upper ends of the body-securing cleats are bolted'to cross bearers of the body, and the lower ends are welded to the longitudinals. This construction obviates weakening the bearers, and as the bolts are accessible from the side, they can be easily renewed. The body position on the chassis is .arranged to limit the overhang to one fifth of the total length. This is done to prevent the end of the body, when tipped, becoming embedded in the material.

The Ford Thames chassis members are normally reinforced by a sub-frame which is bolted to the main members. The Ford sub-frame comprises 6-in. 4iy 1-in, pressed-steel sections, boxed in the vicinity of the hinge assembly and other highly stressed points to form a 6-in. by 2-in. structure. This sub-frame takes the place of the wood bolsters of the Bedford; when bulk loads only are carried, it may be dispensed with and the body supported by the chassis members.

Low Floor Height

The Welford twin-ram units manufactured by the concern are designed for loads up to 15 tons and are fitted between the side-frame members in a manner similar to that adopted in the long-wheelbase conversions. The saving in floor height is about 64 ins.

A special type of built-in rear-hinge assembly is employed which enables the body to be lowered to within 4 in. of the chassis frame, and wood strips are fitted in place of bolsters, A valuable fitting and maintenance feature of the rams is the use of a spacing tube between the top flange and the trunnion 'block, in which the ram is a loose fit.

The height of the ram may be varied by changing the spacing tube without 'detaching the trunnion block or carrying out other dismantling work. In certain instances, other makes of ram in stock are adopted to incorporate this feature so that they may be readily, fitted to many different types of vehicle. The ram is prevented from turning by a clamp.

"One-off" Conversions The ram cylinders are connected to the hydraulic system by high-pressure flexible hoses and no stuffing gland is

required. This reduces maintenance and facilitates installation.

In the category of "special jobs" may be included conversions of old vehicles with unusual features, which prevent the use of an 'under-body assembly, and equipping new vehicles which are unsuitable for the fitting of twin-rams on account of the excessive length between the support bracket and the front of the body. A front-of-body rain is then employed, and if necessary, a stabilizer is fitted to prevent body sway.

A typical old-vehicle conversion was that of an Austin ex-W.D. three-axled chassis with an offset propeller shaft driving the first axle of the bogie. This necessitated the fitting of a front-ofbody ram and the use of a triangulated stabilizer, mounted on a cradle and attached to the body by a sliding trunnion. A 4-in, rolled-steel-channel subframe was bolted to the chassis to compensate for the lack of support at the rear end.

• Other interesting conversions of new vehicles include equipping a Bedford ST type 74-ton chassis with an underfloor type of twin-ram lifting gear.