Tat testing a truck or lipping trailer is an expensive

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

proposition, but Leyland Trucks has come up with a way of simulating it on a computer. Brian Weatherley reports.

If you've ever conducted or viewed a tilt test at the Qinetiq track at Chertsey, Surrey, you'll know exactly what's involved. The expression "labour intensive" could have been written especially for it.

Angus Spooner, product manager for tipping trailers at Crane Fruehauf, explains: "It's at least a day's work just to set a trailer up on the tilt table, including chaining it down and attaching a safety cable to the top corner of the trailer body and hiring a safety crane to prevent it going right over if the wheels lift off or worse still if you get a catastrophic failure of the ram or body.

And that's not counting the time it takes to get a trailer to Chertsey, secure the load on it as well as organising staff to attend the test. When you add it up, it can easily exceed £3,000 per trailer. And in the end it serves only to confirm what you've already calculated... well you hope it does! The purpose is to prove your calculations."

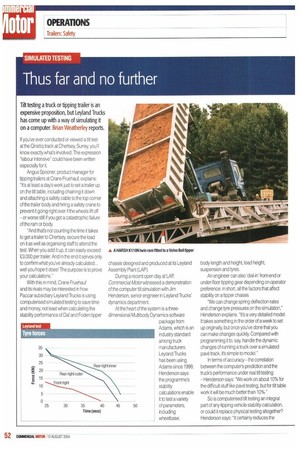

With this in mind, Crane Fruehauf and its rivals may be interested in how Paccar subsidiary Leyland Trucks is using computerised simulated testing to save time and money, not least when calculating the stability performance of Daf and Foden tipper chassis designed and produced at its Leyland Assembly Plant (LAP).

During a recent open day at LAP, Commercial Motorwitnessed a demonstration of the computer tilt simulation with Jim Henderson, senior engineer in Leyland Trucks' dynamics department.

At the heart of the system is a threedimensional Multi body Dynamics software package from Adams, which is an industry standard among truck manufacturers. Leyland Trucks has been using Adams since 1998; Henderson says the programme's stability calculations enable it to test a variety 45 50 of parameters, body length and height, load height, suspension and tyres.

An engineer can also front-end or under-floor tipping gear depending on operator preference: in short, all the factors that affect stability on a tipper chassis.

"We can change spring deflection rates and change tyre pressures on the simulation," Henderson explains. "It's a very detailed model. It takes something in the order of a week to set up originally, but once you've done that you can make changes quickly Compared with programming it to, say, handle the dynamic changes of running a truck over a simulated pave track, it's simple to model."

In terms of accuracythe correlation between the computer's prediction and the truck's performance under real tilt testing Henderson says: "We work on about 10% for the difficult stuff like pave testing, but for tilt table work it will be much better than 10%."

So is computerised tilt testing an integral part of any tipping vehicle stability calculation, or could it replace physical testing altogether? Henderson says: "ft certainly reduces the amount of physical testing you need to do as it provides validation. Rather than simply testing to see how a design is performing, it pushes the test process back to the end of the project."

Leyland doesn't currently offer thirdparty computer simulation to trailer manufacturers, but many of them are likely to be interested in what the Adams software offers.

CF was one of the first UK trailer manufacturers to investigate making tipping trailers more stable, conducting a series of tilt tests at Chertsey as far back as 1981. It has regularly conducted tilt tests on its products, most recently as part of the tender process for the Lafarge contract. Many operators insist that their suppliers' products meet the performance recommendations in the IRTES recently updated Guide to Tipping Stability.

Computer simulation Angus Spooner believes computer simulation could be a useful development in stability calculations: "We'd be interested in the opportunities offered by computerised tilt testing and in particular to see if the correlation between the computer model and the real thing was close enough to persuade operators to accept the computer's finding."

But he adds: "It's unlikely an operator would simply accept a straight calculation, so I'd be surprised if they'd accept a computer simulation as they'd need to be assured it was reliable, We can now calculate reasonably accurately now but operators still prefer a physical test."

This view is echoed by United Trailers (UK) sales director Kevin Pell. He says the company still uses tilt tests in addition to its normal stability calculations: "We'd like to see the programme, although whether that would satisfy everybody is open to debate. Some would still be calling for a percentage of trailers to be tested to back up the theory."

Chris Bartlett, joint MD of Wilcox, is adamant that operators like to see real trailers being tested on a real tilt table: "When we did the Lafarge contract it wanted a physical test. It wanted to see the trailer perform under test. The problem with computers is they're only as good as the information you put into them. It would need to be 100% guaranteed accurate before it gave you the right answer on stability.

"Suspension plays a very important part in stability," he adds, "but getting information out of the axle and suspension manufacturers isn't easy" Graham Ellis is one of the authors of the Guide to Tipper Stability. As chairman of the IRTE's tipper stability working party committee he gives computer simulation a guarded welcome: "There have been a couple of simulations around for some time. We've never said we don't accept simulation. What we've said is we'd want at least one physical test such as type approval to confirm the simulation."