MODELS FOR MEDIUM AND HEAVY LOADS.

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

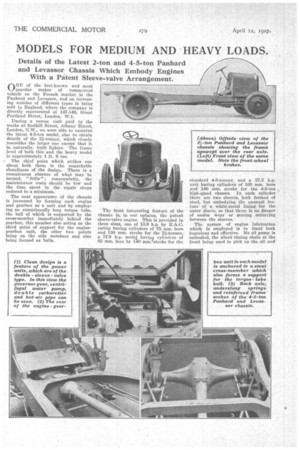

Details of the Latest 2-ton and 4-5-ton Panhard and Levassor Chassis Which Embody Engines With a Patent Sleeve-valve Arrangement.

ONE of the best-known and most 1._/popular makes of commercial vehicle on the French market is the Panhard and Levassor, and an increasing number of different types is being sold in England, where the company is directly represented at 147-149, Great Portland Street, London, W.1.

During a recent visit paid to the works at Itedhill Street, Albany Street, London, N.W., we were able to examine the latest 4-5-ton model, also to obtain details of the 21-tonner, which closely resembles the larger one except that it is, naturally, built lighter. The frame level of both this and the heavy model is approximately 1 ft. 9 ins.

• The chief point which strikes one about both these is the remarkable cleanliness of the design. There is a conspicuous absence of what may be termed. "frills"; consequently, the maintenance costs should he low and the time spent in the repair shops reduced to a minimum.

The neat appearartee of the chassis is increased by forming each engine and gearbox as a unit and by employing an exceptionally long torque tube, the ball of which is supported by the cross-member immediately behind the gearbox, this member also acting as the third point of support for the enginegearbox unit, the other two points being on the side members and also being formed as balls.

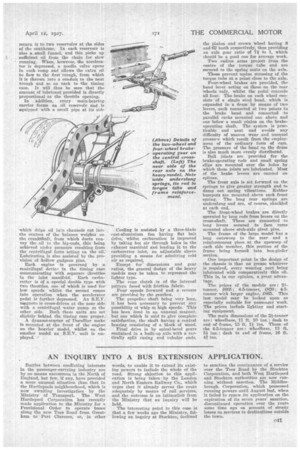

The frnost interesting feature of the chassis is, in our opinion, the patent sleeve-valve engine. This is provided in three sizes, one of 13.0 h.p. by R.A.C. rating having cylinders of 75 mm. bore and 130 mm. stroke for the 2i-tonner, a 17.9 h.p. model having cylinders of 85 mm. bore by 110 mm.cstroke for the

standard 4-5-tonner, and a*27.3 h.p. unit having cylinders of 105 mm. bore and 140 mm. stroke for the 4-5-ton high-speed chassis. In each cylinder there are two sleeves, both formed of steel, but embodying the unusual feature of a white-metal lining for the outer sleeve, so that there is no danger of undue wear or scoring occuriing between the sleeves.

The system of engine lubrication which is employed is in itself both ingenious and effective. No oil pump is embodied, the silent timing chain at the front being used to pick up the oil and return it to two reservoirs at the sides of the crankcase. In each reservoir is also a small funnel, and this picks up sufficient oil from the chain for slow running. When, however, the accelerator is depressed, a needle valve opens in each sump and allows the extra oil to flow to the first trough, from which it is thrown into a conduit to the next trough and so on back to the timing ease. It will thus be seen that the amount of lubricant provided is directly proportional to the throttle opening.

In addition, every main-bearing, carrier forms an oil reservoir and is equipped with a small pipe at its side which drips oil into channels cut into the centres of the balance weights on the crankshaft, from which ducts convey the oil to the big-ends, this being achieved under pressure resulting from the centrifugal force acting on the oil.' Lubrication is also assisted by the provision of hollow gudgeon pins.

Each engine is governed by a centrifugal devic? in the timing ease communicating with separate throttles in the inlet manifold. Each carburetter is of a special double type with two throttles, one of which is used for low speeds whilst the second comes into operation when the accelerator pedal is further depressed. An S.E.V. magneto is cross-driven at the near side with a centrifugal water pump at the other side. Beth these units are set slightly behind th timing case proper.

A dynamo-starter of Ducellier make is mounted at the front of the engine on the heavier model, whilst on the smaller model an S.E.V. unit is employed. Cooling is assisted by a three-blade east-aluminium fan having fiat belt drive, whilst carburation is improved by taking hot air through holes in the exhaust manifold and leading it to the carburetter inlet, an adjustable sleeve providing a means for admitting cold air as required. Except for" dimensions and gear ratios, the general design of the heavy models may be taken to represent the lighter type.

The cone clutch is of the internal pattern faced with friction fabric.

Four speeds forward and a reverse are provided by the gearbox.

The propelles shaft being very long, it has been necessary to 'prevent any possibility ot whip at high speeds. This has been done in an unusual manner, but one which is said to give complete satisfaction, the shaft having a central bearing consisting of a block of wood.

Final drive is by spiral-bevel gears contained in a built-up axle with a vertically split casing and tubular ends, the pinion and crown wheel having 8 and 62 teeth respectively, thus providing an axle gear ratio of 7i to 1, which should be a good one for average work.

Two radius arms project from the centre of the torque tube and are secured to the spring seats on the axle.

These prevent undue stressing of the torque tube at a point close to the axle.

Four-wheel brakes are provided, the hand lever acting on those on the rear wheels only, whilst the pedal controls all four. The brake on each wheel consists of a single steel band, which is expanded in a drum by means of two levers, each connected at two points to the brake band and connected to parallel racks mounted one above and one below a small pinion on the brake. operating shaft. The -system is practicable and neat and avoids any difficulty of uneven wear and unequal pressure which result from the employment of the ordinary form of cam. The pressure of the band on the drum is also much more evenly distributed.

Ball joints are provided for the brake-operating rods and small spring clips are mounted over the holes by which these joints are lubricated. Most of the brake levers are carried on splines.

The front axle is set forward on the springs to give greater strength and to damp out spring vibrations. Rubber bumpers are mounted above each front spring. The long rear springs arc underslung and are, of course, shackled at each end.

The front-wheel brakes are directly operated by long rods from levers on the cross-shaft. These are connected to long levers secured to face cams mounted above stub-axle pivot pins.

The frame of the large model has a long outsweep to the rear and a reinforcement piece at the upsweep of each side member, this portion of the frame being formed into box-girder section.

One important point in the design of the chassis is that no grease whatever is required, every wearing part being lubricated with comparatively thin oil. This is, in our opinion, a great advantage.

The prices of the models are : 21tonner, £605; 4-5-tonner, £820; 4-5tonner with larger engine, £865. This last model may be looked upon as especially suitable for passenger work. The prices include lighting and starting equipment.

The main dimensions of the 21-tonner are : wheelbase, n ft. 10 ins.; dash to end of frame, 13 ft. 11 ins. Those of the 4-5-tonner are: wheelbase, 13 ft. 51 ins.; dash to end of frame, 16 ft. 41,iins.