TWO IMPORTANT INTROE BY SCAMMELL

Page 74

Page 75

Page 76

Page 79

If you've noticed an error in this article please click here to report it so we can fix it.

THERE are to be two important introductions of vehicles by Scamniell Lorries Ltd. at the Commercial Motor Show. The main one—an eventual replacement for the Scarab—will be the Townsman three-wheeled tractive unit for use with 3and 4-ton semi-trailers. The second is the Handyman III tractive unit, which has a modified version of the plastics cab used on the Routeman eight-wheeler.

Although the Townsman is based on the Scarab and resembles this earlier three-wheeler, it is a complete re-design. Virtually nothing from the Scarab is used except the gearbox, other items being coupling hooks and fuel tank and a few minor parts in the coupling gear. The rear axle is similar to the Scarab but is a singlereduction unit instead of double-reduction and is to be offered in one ratio only-5-625 to 1. The frame is a new design and, although following the same design as the Scarab-Four at the rear and being all welded, it is a onepiece assembly, not two-piece.

The most significant changes are in respect of the cab, engine and braking system. The cab is a one-piece reinforced-plastics moulding and this fits on a sub-structure which is also a one-piece moulding of the same material. There is no timber or steel in the cab, all structural mem bers being of plastics. The design of the cab is improved in a number of respects from the old Scarab, providing improved visibility through a larger one-piece curved screen, while twin headlights are located below the bottom sill.

Driver and passenger doors are wider than previously, and the new cab has an engine air intake located above the windscreen, this leading through ducting built into the roof and going down the back. The position of this duct means that no central window can be fitted at the rear of the cab; but good-sized windows are fitted at both sides and these curve slightly round the rear corners. Interesting fittings are solid rubber blocks built into the rear corners of the cab in the area where the side raves of semi-trailers would make contact in the jack-knife position. The size of the blockt makes allowance for all semi-trailers likely to be used with the Townsman. Safeguarding against possible frontal damage is a curved bumper, as on the Scarab.

From the maintenance point of view, it will be an advantage that the whole of the cab is easily removable from the base structure—all controls are in the base and only the windscreen wipers and lights have to be disconnected.

New Engine

The engine used in the Townsman is the new Leyland Group 0E160 diesel engine. This engine is described on page 78 of this issue, being a bored-out version of the 0E.138 (this was the Standard CV.23) and having a capacity of 2,160 c.c. (138 cu. in.). Maximum net output of the 0E.160 is 58 b.h.p. at 3,000 r.p.m. against 52 b.h.p. at the same speed for the 0E.138, and maximum net torque is 119 lb. ft. against 101 lb. ft.—both at 2,000 r.p.m. The fitting of a new crankshaft gives an increase in stroke from 4-0 in. to 4.25 in., while the bore is increased from 3.313 in. to 3.455 in.

Changes to the braking system will be welcomed by potential operators. Brakes are.now hydraulically operated with vacuum assistance from a Clayton Dewandre Hydro

vac and, although the front wheel continues to be unbraked, it is likely that a front brake will be offered in the future, particularly for overseas service. There is no change in the size of the brake units fitted at the driving-axle wheels, these being Girling 12 in. by 2.5 in, leading-and-trailing shoe. Operation of the brake linkage to the automatic coupling for semi-trailer brake application is the same as on the Scarab.

Other Differences

Other differences between the Townsman and Scarab are that the clutch is enlarged from 9-25 in. to 10 in. diameter, the rear springs arc now dual-rate and have increased movement, and hydraulic damping is built into the front suspension which otherwise differs only in having modifications to give improved ride. The radiator now incorporates a plastics expansion tank to provide a "no loss" system and, for the record, the four-speed constant-mesh gearbox retained from the Scarab has ratios of 6,3, 3.01, 1.68 and 1 to 1, with reverse 8.4 to 1.

The driver's seat is fixed, but, to allow for variation in driver size, the control pedals are easily adjustable. The clutch on the Townsman is hydraulically operated, the master cylinders for it and the brakes being mounted on a plate together with the pedals. The assembly fits on to a bracket, where it can be adjusted by as much as 4 in. fore and aft by means of a small Winder.

Overall dimensions of the Townsman, with comparable figures for the Scarab 3-tonner in brackets, are: length, about 14 ft. 5-5 in. (14 ft. 0.7$ in.), height 6 ft. 4 in. (6 ft. 7 in.), width 5 ft. 10 in. (5 ft. 7 in.). The wheelbase is 9 ft. 2.625 in. against 8 ft. 10-75 in. and the rear track is the same at 4 ft. 8 in.

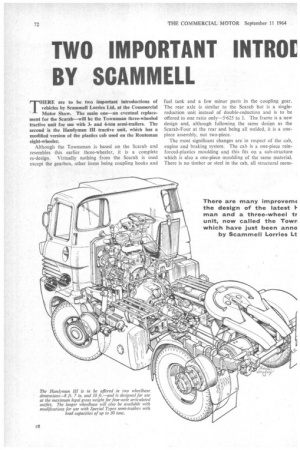

A good deal of alteration has been made to the design of the Handyman tractive unit—the new model is the Mark El—quite apart from the fitting of the Routeman-style cab. The cab is not exactly the same as the one fitted to the Routernan, being set right over the front axle instead of partly forward of it, and therefore losing the forwardentry feature. The Handyman 111 is to be offered in two wheelbase dimensions-8 ft. 7 in. and 10 ft. The model is designed for use with tandem-axle semi-trailers running at the maximum legal gross weight for four-axle .outfits; but the longer wheelbase will also be available (suitably modified in respect of axles, suspension and so on) for use with Special Types semi-trailers with toad capacities of up to 30 tons. In the latter case the Handyman will duplicate the capacity of the Highwayman normal-control tractive unit, which is also designed for 30-ton loads. This will mean that both forwardand normal-control units will be available for use with machinery-carrier semi-trailers and the like. There are, of course, higher capacity versions of the Highwayman, though normally these are specially designed to particular requirements.

Three Engine Options Three engines are available in the Handyman 111: the Leyland Power-Pius 0.680 (which is standard), the PowerPlus 0.600 and Gardner 6LX. The offering of Leyland Power-Plus diesels is new to the Handyman, the Mark II being available with the earlier 0.680 unit as standard although the Gardner 6LX was the alternative then. The three options of engine mean that alternative maximum net power outputs are available of 200 b.h.p. at 2,200 r.p.m. for the 0.680, 140 b.h.p. at 2,200 r.p.m. for the 0.600, and 150 b.h.p. at 1,700 for the LX.

In the case of the two Leyland engines, the drive is taken through a 16-25 in, clutch which is hydraulically operated and in the case of the 0.680 engine has air-pressure assistance. With the Gardner, a 16-in, diameter clutch is employed. The same Scammell six-speed constant-mesh gearbox as used on the Handyman II is employed, this having ratios of 6.55, 4.07, 2-53, 1-61, 1.0 and 0-622 to 1 with reverse 8.37 to 1 in standard form,

although other gear ratios can be supplied to individual requirements. There is a slight change in the radiator fitted to the chassis, this being a one-piece unit four-row Morris stack-tube type, and with the 0.680 engine a noloss" system is employed.

No change has been made in the frame design for the Mark HI version in the case of the 8 ft. 7 in. wheelbase, the pressed-steel channel section being 8 in. deep, 0-25 thick and with 3.5 in. flanges. With the 10 ft. wheelbase, however, the frame is 0-5625 in. thick and the depth is increased because of this to 8-125 in. The frame is of bolted construction and employs tubular cross-members except at the front where it is pressed-steel channel section. There has been little change in the suspension, the semielliptic springs being still 3 in wide but they are now shorter to overcome a tendency towards softness.

Telescopic dampers continue to be fitted at all wheels, except in the case of the 30-ton-load model where there is a higher capacity rear axle and the springs all round are very much heavier. The front axle has been strengthened for use on the 4ark III and now has a 5-ton capacity. General design if the Scammell fully-floating spiral bevel and epicyclic ouble-reduction rear axle is also the same; but the load apacity has been increased to 10 tons at the ground for ie 24-ton g.t.w. model. For the unit designed for 30-ton Tads a heavier axle with a 14-ton load capacity is used. Final-drive ratios available are unchanged, these being -44, 7-13, 7.78, 8-56 and 9.4 to.1 with 10.25 and 11.2 to 1 dded for the 30-ton load capacity version.

Iram Brakes Leyland S-type cam brakes are fitted to the front and ear axles, drum diameters being 15.5 in. whilst the front nings are 4.25 in. wide and the rear 7 in. wide. Frictional reas are 225 sq. in. front and 379 sq. in. rear, making a Ttal frictional area of 604 sq. in. Brake operation is by ir pressure, which is also used to assist actuation of the -active unit handbrake. A hand valve for semi-trailer rake operation is provided in the cab. This layout is to le same specification as the Handyman 11; but, as few I this model were made, it is relevant that the operation I the brakes should be more satisfactory than on the /lark I which had Girling toggle brakes all round.

In the Mark III, the air systems to the circuits for the 3ot brakes, semi-trailer hand valve and handbrake assistnee are so arranged that a failure in one circuit does not nder ineffective the circuits of the others. This is done y having separate reservoirs for the foot and hand brake, nd, of course, there will be the usual reservoir on the yreS A whole range of tyre equipment is available to specication, for the 24-ton g.t.w., these being 9-00or 10-00o or 24 in. by 6in. rims. For the 30-ton load model 1.00 and 12.00 tyres are offered in addition, with the same im sizes; but Scammell recommends 9-00-24 for the front 'heels and 11.00-24 twins for the rear.

Various couplings are also available, including two A.E. fifth-wheel models by Scammell—these are the .andard fitting. One is a heavy duty version for the 30mner which will also be available for other ScammelI models eventually, and both have as standard newlydesigned lead-on ramps to aid the coupling of the unit to semi-trailers. There are also two turntables, one the recently modified Spherub to suit 24 tons g.t.w., the other a heavy-duty model for the 30-ton-load version. Strictly speaking the former should not now be called Spherub because the modifications included a change from semispherical rubber bushes to cylindrical types. There is also the Scammell heavy-duty fully-automatic coupling which is air operated; but this model is not available for the 30ton load chassis.

Options Other items in the specification of the Handyman II are a 55 gal. fuel tank, a 24V double-pole electrical system and

an instrument panel as fitted to the Routeman II. A comprehensive list of optional equipment is available including a firescreen. power-take off, automatic chassis lubrication, Smiths heating and demisting equipment and a full-width bumper.