A NEW 6-7-TON OV

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

TYPE STEAM WAGON.

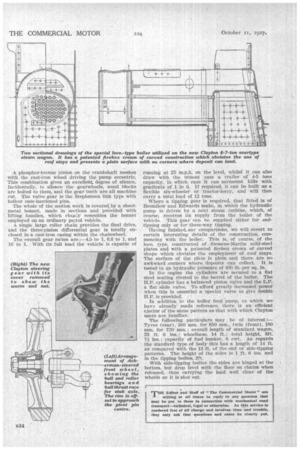

Details of the Latest Clayton Pro on Previous Designs, including Acke

which Embodies Many Improvements Steering, Three Speeds, and Crankshaft and Roller Bearings. and Wheels on

S0 much attention has been paid during recent months to the development of the petrol vehicle, particularly that employed for passenger use, that there has been a tendency to negieet that essentially British product, the steam wagon. This tendency is one which is unjustified, and will, if it continues, have a serious effect on the whole steam-wagon industry.

There is an inclination for the makers of the steam wagon to hide its light under a bushel, and it was with a view to removing this " bushel " that we conceived the idea of a really representative demonstration of steam wagons which, we are glad to state, is developing in a most satisfactory manner, and should do much to bring before the notice of potential users of road transport vehicles and those who are considering amplifying or renewing existing fleets, a type of vehicle which has a great many qualifications in its favour, including that of utilizing a fuel originating in this country, and thus assisting in finding employment for British labour.

Even in connection with the two main classes of steam wagon, the undertype and the overtype, despite the rapid advancement of the former there are still many classes of work for which the overtype is eminently suitable. This particularly applies to work which involves the negotiating of exceptionally rough roads or uneven surfaces, as where a vehicle may be called upon to run into and out of quarries, over building sites, and so forth.

Clayton Wagons, Ltd., Abbey Works, Lincoln, fully realizes this, and it. is developing the overtype side by side with the well-known Clayton undertype, with the result that the latest model incorporates a large number of technical improvements which will certainly do much to render the new 6-7-ton machine popular amongst users. Already, a number of the, new models is in use or on order.

Improvements can only be indicated by comparison, and to do thig adequately we will deal first with the main 'differences between the new model and the 6-ton overtype which it has superseded.

The engine has H.P. and L.P. cylinders of 4i ins. and 7 ins. diameter respectively, the stroke being 7 ins. In the previous engine the diameter of the H.P. cylinder was 41 ins. To take the extra stresses involved, the dimensions of the crankpins and motion work have been increased correspondingly. This engine runs at a normal speed of 500 r.p.m., giving 15 m.p.h. in high gear, but to supply it the boiler heating surface is now 90 sq. ft. instead of 70 sq. ft., whilst the grate area has been increased from 2.5 sq. ft. to 3.6 sq. ft., and the working pressure from 200 lb. per sq. in. to 230 lb. One of the greatest improvements lies in connection with the steering, which is now on the Ackerman principle, and the front suspension is by two long semi-elliptic springs. The steering gear itself Is of the worm-and-nut type, of most substantial construction and having ball-thrust washers above and below the worm.

Another important difference lies in the employment of a three-speed gear instead of only two speeds. In order to comply with the latest requirements, an entirely new brake arrangement is employed. The pedal brake expands large shoes in a drum on each wheel, whilst for the hand brake an additional single shoe acts on an independent ring secured to each rear wheel and air-spaced from it. Reference to our illustrations will show the arrangement of these shoes and the large frictional area presented both by the single and double shoes. Both operating cams are on the same spindle, but, of course, controlled separately, the inner cam being that for the single shoe. A neat swinglink type of compensator is provided for each set of brakes.

The cast-steel wheels are of the Y-spoked pattern, those at the front being arranged to take Clayton front-wheel brakes as optional equipment. The front wheels run on ball and roller bearings.

An important point in the latest design is in connection with the comfort of the driver and second man. The steering and all controls are under the direct supervision of the driver, so that only a youth is required for firing. The cab and seating are so arranged that adequate leg-room is afforded and, what is of even greater importance, the driver is able to obtain a good view of the road. Protection from inclement weather is afforded by a flat windscreen.

To cope with the extra stresses involved by the increased load capacity and more powerful engine, the depth of the framechannels has been increased from 6 ins. to 7 ins. Thirty to thirty-five miles can be achieved on a tankful of water, which is 210 gallons, as compared with the 170 gallons of the tank previously employed. • _

Ball and .roller bearings are now employed for the crankshaft and, as the life of such bearings is exceptionally long, maintenance will be rendered much easier. There is also the advantage that there can be little or no difference in the meshing of the gear teeth, which sometimes causes trouble through the shaft settling.

A further improvement is that the feed pump is independently driven at half engine speed, so that it is kept in action while the engine is running with the gear in neutral. A phosphor-bronze pinion on the crankshaft meshes with the cast-iron wheel driving the pump eccentric. This combination gives an excellent, degree of silence. Incidentally, to silence the gearwheels, wood blocks are bolted to them, and the gear teeth are all machine cut. The valve gear is the Stephenson link type with hollow case-hardened pins.

The whole of the motion work is covered by a sheetmetal bonnet, made in sections and provided with

lifting handles, which resembles the bonnet. employed on an ordinary peaol vehicle.

A single large roller chain provides the final drive, and the three-pinion differential gear is totally enclosed in a cast-iron casing within the chainwheel.

The overall gear ratios are :-4.5 to 1, 6.6 to 1, and 16 to 1. With its full load the vehicle is capable of

running at 25 m.p.h. on the level, whilst it can also draw with the utmost ease a trailer of 4-5 tons capacity, in which case it can surmount hills with gradients of 1 in 6. If required, it can be built as a flexible six-wheeler or tractor-lorry, and will then carry a total load of 12 tons.

Where a tipping gear is required, that fitted is of Bromilow and Edwards make, in ,which the hydraulic pump is driven by a neat steam turbine, which, of course, receives its supply from the boiler of the vehicle. This gear can be supplied either for endtipping only or for three-way tipping.

Having finished, our comparisons, we will revert to certain interesting details of the construction, commencing with the boiler. This is, of course, of the loco. type, constructed of Siemens-Martin mild-steel plates and with a patented firebox crown of curved shape which obviates the employment of roof stays. The surface of the plate is plain and there are no awkward corners where deposits call collect. It is tested to an hydraulic pressure of 400 lb. per sq. in.

In the engine the cylinders are secured to a flat steel seating riveted to the barrel of the boiler. The H.P. cylinder has a balanced piston valve and the L.P. a fiat slide valve. To afford greatly increased power when this is essential a special valve to give double H.P. is provided.

In addition to the boiler feed pump, to which we have already made reference, there is an efficient ejector of the same pattern as that with which Clayton users are familiar.

The following particulars may he of interest:— Tyres (rear), 160 mm. for 850 mm., twin (front), 180 mm. for 720 mm.; overall length of. standard wagon, 23 ft. 6 ins.; wheelbase, 14 ft.; total height, 8ft. 7-I ins.; capacity of fuel bunker, 6 cwt. As regards the standard type of body this has a length of 14 ft. as compared with the 13 ft. of the end or side-tipping patterns. The height of the sides is 1 ft. 6 ins, and in the tipping bodies, 2ft.

With side-tipping bodies the sides are hinged at the bottom, but drop level with the floor on chains when released, thus carrying the load well clear of the wheels as it is shot out.