COMPRESSED GAS FOR ROAD TRANSPORT.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

A London Company Ready to Fit Complete Installations to Commercial Vehicles.

It is generally recognized that while the flexible overhead container offers a ready means of carrying coal-gas for motor fuel purposes it is unable to meet all and every traffic condition. At the moment the compression system is the alternative, and from the many inquiries we have received in this connection, this method of carrying the fuel is certain to meet with a wide vogue.

Hitherto certain difficulty has been experienced in carrying out complete installations upon a commercial scale, but one firm informs us that it is now ready to step into the breach. This is Flugel and Co., Ltd., 33a, Green Lanes, London, N. 16. This house has been prominently identified with the manufacture of soda water bottling machinery for many years, and thus is familiar with the problems incidental to the charging of ,cylinders or metal bottles with gas at high pressure, its subsequent release, and conduct through reducing and balancing valves to the point where the energy is required.

They possess a large stock of cylinders as well as the necessary valves, and consequently are in the position to carry out installations without delay. The cylinders, varying in dimensions and consequent cubic capacity, have been fashioned to meet a pressure of 250 atmospheres---3675 lb. per sq. in.—and may safely be charged up to a pressure of 125 atmospheres, or, say, 1837 lb. per sq. in., and even to 150 atmospheres. The largest cylinders, measuring 98 ins, length by 8 ins. diameter (internally), have a capacity of 14 cubio ft., and at the foregoing pressure of 125 atmospheres would carry about 170 cubic ft. of gas. The weight of such a cylinder is approximately 112 lb.

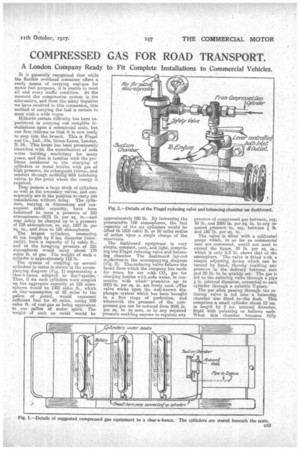

The system of coupling up several cylinders in series is shown in the accompanying diagram (Fig. 1) representing a char-a-banes adapted to then system.• Thus, if six such cylinders were coupled up the aggregate capacity at 125 atmospheres would be 1000 cubic ft., which on the--assumption of 10 miles to the gallon of petrol, would represent sufficient fuel for 40 miles, rating 260 cubic ft. of coal-gas as being equivalent to one gallon of motor spirit. The weight of such an outfit would be

approximately 680 lb. By increasing the preasurOto 150 atmospheres, the fuel capacity of the six cylinders would be lifted to 1200 cubic ft. or 50 miles radius of action upon a single charge of the reservoirs,

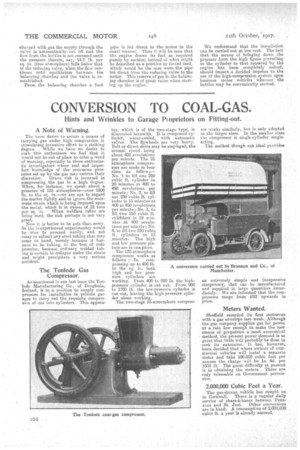

The dashboard equipment is very simple, compact, neat, and light, comprising one Flugel reducing valve and balancing chamber. The dashboard lay-out isehownf in the accompanying diagram (Fig. 2). Thsereducing valve.follows the broad lines which the company has made for years, for use with CO2 gas for charging bottle a with soda water, in connection with which" pressures up to 2000 lb. per sq. in. are freely used. ,The valve works upon the well-known diaphragm system which has been brought to a fine stage of perfection, and wherewith the pressure of the compressed gas can be reduced from 2000 lb. per sq. in. to zero, or to any required pressure enabling anyone to regulate any

pressure of compressed gas between, say, 30 lb. and 2000 lb. per sq. in. to any re quired pressure to, say, between lb. and 150 lb. per sq. in.

The valve is fitted with a calibrated gauge which, in so far as commercial ears are concerned, would not need to exceed the figure, 20 lb. per sq. in., which is only 5.3 lb. above that of the atmosphere. The valve is fitted with a simple adjusting device which can be turned by hand, thereby enabling any pressure in the delivery between zero and 20 lb. to be quickly set. The gas is led to the reducing valve through a pipe ik in. internal diameter, connected to each cylinder through a suitable T-piece.

The gas after passing through the reducing valve is led into a balancing chamber also fitted teethe dash. This comprises a small cylinder about 12 ins. in length by 3 ins, internal diameter, fitted with pulsating or bellows ends. When this chamber becomes fully

charged with gas the supply through the valve is automatically cut off and the flow from the bottles is not resumed until the pressure therein, say, 14.7 lb. per sq.-in. (free atmosphere) falls below that of the reducing valve, when the flow continues until equilibrium between the balancing chamber and the valve is reestablished.

From the balancing chamber a feed

pipe is led direct to the motor in the usual manner. Thus it will be seen that the engine draws its fuel as required purely by suction, instead of what might be described as a positive or forced feed, which mould be the case were the pipe led direct from the reducing valve to the motor. This reserve of gas in the balancing chamber is of great value when starting up the engine.

We understand that the installation can be carried out at low cost. The fact that the means of bringing down the pressure from the high figure prevailing in the cylinder to that required by the engine has been completely solved, ehould impart a decided impetus to the use of the high-compression system upon business motor vehicles whereon the bottles may be conveniently stowed.