A British-Built Paraffin Wagon.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

Unique Features Introduced by a High Wycombe Firm of Makers.

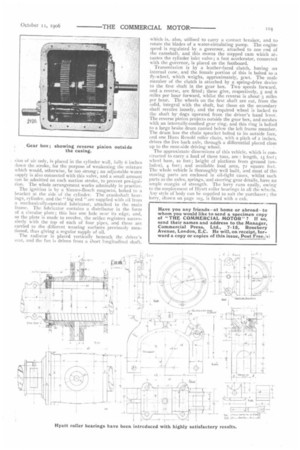

It is a rare occurrence among designers of commercial vehicles to lind one whois sufficiently courageous to embody, in a new model, any radical departure from the generally accepted lines which are now in fashion. Manufacturers, as a whole, appear to be under the impression that, in order to obtain a fair share of the orders which are continually being placed, it is only necessary to incorporate a few new details with what may be called the existing standard designs. A representative of " THE COMMERCIAL MOTOR " recently inspected an explosion-motor lorry which departs greatly in the disposition of its various parts from anything at present on the market. The vehicle in question has been constructed by Broom and Wade, Limited, of Desboro' Iron Works, High Wycombe, to the order of Barclay and Perkins, Limited, the well-known brewers, for the conveyance of beer from a central depot in London to distant tied houses.

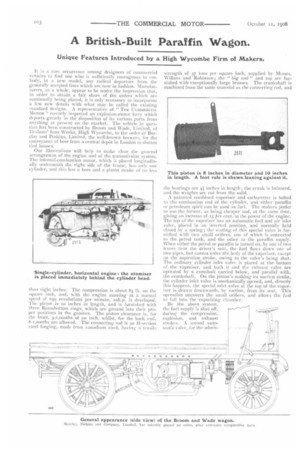

Our illustrations will help to make clear the general arrangement, of the engine and of the transmission system. The internal-combustion motor, which is placed longitudinally underneath the right side of the frame, has only one cylinder, and this has a bore and a piston stroke of no than eight inches. The compression is about 85 lb. on the square inch, and, with the engine running at a normal speed of 65o revolutions per minute, 2oh.p. is developed. The piston is to inches in length, and is furnished with three Ramsbottom rings, which arc ground into their proper positions in the grooves. The piston clearance is, for the front, 3-t,onoths of an inch, whilst, for the back end, 8-1,000ths are allowed. The connecting rod is an H-section steel forging, made from vanadium steel, having a tensile

strength of 37 tons per square inch, supplied by Messrs. Winans and Robinson; the " big end " and top are furnished with exceptionally large brasses. The crankshaft is machined from the same material as the connecting rod, and the bearings are 41 inches in length; the crank is balanced, and the weights are cut from the solid.

A patented combined vaporiser and carburetter is bolted to the combustion end of the cylinder, and either paraffin or petroleum spirit can be used as fuel. The makers prefer to use the former, as being cheaper and, at the same time, giving an increase of 25 fret cent. in the power of the engine. The top of the vaporiser has an automatic fuel and air inlet valve, placed in an inverted position, and normally held closed by a spring; the seating of this special valve is furnished with two small orifices, one of which is connected to the petrol tank, and the other to the paraffin supply. When either the petrol or paraffin is turned on, by one of two levers near the driver's seat, the fuel flows down one of two pipes, but cannot enter the bcdy of the vaporiser, except on the aspiration stroke, owing to the valve's being shut. The ordinary cylinder inlet valve is placed at the bottom of the vaporiser, and both it and the exhaust valve are operated by a camshaft carried below, and parallel with, the crankshaft. On the piston's making its suction stroke, the cylinder inlet valve is mechanically opened, and, directly this happens, the special inlet valve at the top of the vaporiser is drawn downwards, by suction, from its seat. This operation uncovers the small orifices, and allows the fuel to fall into the vaporising chamber.

By the above system, the -fuel supply is shut off, during the compression, explosion, and exhaust strokes. A second automatic valve, for the admis

sion of air only, is placed in the cylinder wall, fully 6 inches down the .stroke, for the purpose of weakening the mixture which would, otherwise, be too strong ; an adjustable water supply is also connected with this valve, and a small amount wan be admitted on each suction stroke, to prevent pre-ignition. The whole arrangement works admirably in practice. The ignition is by a Simms-Bosch magneto, bolted to a bracket at the side of the cylinder. The crankshaft bearings, cylinder, and the " big end " are supplied with oil from a mechanically-operated lubricator, attached to the main frame. The lubricator contains a distributor in the form of a circular plate; this has one hole near its edge, and, as the plate is made to revolve, the orifice registers successively with the top of each of four pipes, and these are carried to the different wearing surfaces previously mentioned, thus giving a regular supply of oil. The radiator is placed vertically beneath the driver's swat, and the fan is driven from a short longitudinal shaft, • which is, • also, utilisedto carry a contact breaker, and to rotate the blades of a water-circulating pump. The engine speed is regulated by a governor, attached to one end of the camshaft, and this moves the stepped cam which actuates the cylinder inlet valve ; a foot accelerator, connected with the governor, is placed on the footboard.

Transmission is by a leather-faced clutch, having an internal cone, and the female portion of this is bolted to .a fly-wheel, which weighs, approximately, scwt. The male member of the clutch is attached by a spring-drive device to the first shaft in the gear box. Two speeds forward, and a reverse, are fitted; these give, respectively, 5 and 8 miles per hour forward, whilst the reverse is about 3 miles per hour. The wheels on the first shaft are cut, from the solid, integral with the shaft, but those on the secondary shaft revolve loosely, and the required wheel is locked to the shaft by dogs operated from the driver's hand lever. The reverse pinion projects outside the gear box, and meshes with an internally-toothed gear ring, and this ring is bolted to a large brake drum carried below the left frame member. The drum has the chain sprocket bolted to its outside face, and one Hans Renold roller chain, with a pitch of 2 inches, drives the live back axle, through a differential placed close up to the near-side driving wheel.

The approximate dimensions of this vehicle, which is constructed to carry a load of three tons, are : length, 15 feet ; wheel base, to feet; height of platform from ground (unladen), 4 feet; and available load area, 72 square feet. The whole vehicle is thoroughly well built, and most of the moving parts are enclosed in oil-tight cases, whilst such parts as the axles, springs, and steering gear details, have an ample margin of strength. The lorry runs easily, owing to the employment of Hyatt roller bearings in all the whets. _Thy style of body can be supplied to suit the purchaser; the lorry, shown on page 103, is fitted with a cab.