It's many years since turbochargers took over from superchargers as

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

the standard method of boosting efficiency — but in a bid to overcome the turbocharger's inherent shortcomings Volvo engineers have turned these old rivals into allies ...

• Everyone knows that turbocharged diesels offer more power than their naturally aspirated counterparts. But a turbo is driven by exhaust gas, so at low revs — just when some extra torque would be particularly welcome — much of that extra efficiency simply isn't there.

For long-haul trunking the dreaded turbo lag is no more than a minor inconvenience, but it can be a real pain for urban distribution, and the need for instant throttle response on site work accounts for the survival of big, naturally aspirated diesels in construction chassis. So if more cubes can supply all the power you need without the complexity of a turbo, why all this fuss about blowers? There are two good reasons: fuel consumption and exhaust emissions.

Even if fuel costs weren't a consideration, environmental legislation is likely to consign naturally aspirated diesels to the history books.

Which brings us back to turbo lag. Developing a turbo-diesel with the throttle response of a naturally aspirated lump has long been a holy grail for engine designers. British turbo specialists have been at the forefront in this area, with much research carried out by the likes of Holset in Huddersfield and Garrett in Skehriersdale.

Lessons have been learned from aero engine and industrial gas turbine technology. Compressors and turbine blades have been modified to do their job more efficiently, allowing the rotor to be made smaller, lighter and therefore more responsive to changes in exhaust gas flow.

Smaller turbochargers equipped with wastegates are currently fashionable as a means of boosting the quantity of low-rev induction air delivered by the turbocharger: variable-geometry (swivelling) turbine blades might be a more effective, but more costly, alternative.

RESEARCH

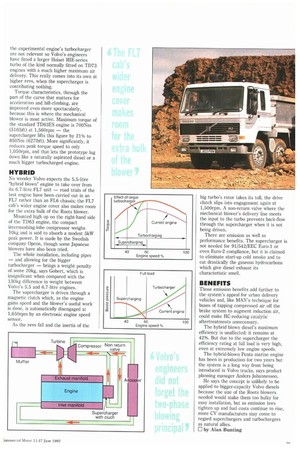

During the mid-eighties, with essentially the same object in view, Volvo ploughed a good deal of research time and effort into sequential turbocharging. Two turbochargers were fitted on a TD120 engine, one significantly bigger than the other. At low engine speeds the small (car-engine sized) turbo was active and the exhaust flow from the 12-litre diesel was enough to achieve a generous air delivery.

As engine speed increased the exhaust gases were diverted progressively to the bigger turbo which, above about 1,500rpm, had taken over as the main charge air supplier. The sequential-turbocharging project was dropped as too complex, expensive and bulky, but Volvo's engineers did not forget the two-phase blowing principle. At the recent Hanover Show Volvo displayed a 5.5-litre truck engine sporting a turbocharger — and a mechanically driven supercharger. The small first-stage turbo was replaced by a compact vee-belt-driven Roots blower which gives even better response than the sequential turbo system: as good as a naturally aspirated engine, says project engineer Ulrich Gobert.

ACCELERATE

The time taken for the engine to accelerate under full load from idle to 1,500rpm is reduced from 3-5 seconds to less than one second.

The add-on supercharger was first tried on a marine derivative of the 5.5-litre engine developed by Volvo's Penta division. In a boat, with the aid of cold "scooped up" intercooling water, it produces 228kW (306hp).

In a truck with conventional air-air charge-cooling, 186kW (250hp) is seen as a more realistic figure, but even that is 19% up on the 157kW (210hp) available from Volvo's most powerful 5.5-litre truck engine, the TD63ES unit used in FL6 chassis.

With the supercharger taking over at low revs the low-speed characteristics of the experimental engine's turbocharger are not relevant so Volvo's engineers have fitted a larger Holset HIE-series turbo of the kind normally fitted on TD73 engines with a much higher maximum air delivery. This really comes into its own at higher revs, when the supercharger is contributing nothing.

Torque characteristics, through the part of the curve that matters for acceleration and hill-climbing, are improved even more spectacularly, because this is where the mechanical blower is most active. Maximum torque of the standard TD63ES engine is 700Nm (516lbft) at 1,560rpm — the supercharger lifts this figure by 21% to 850Nm (627lbft). More significantly, it reduces peak torque speed to only 1,050rpm, and that lets the prototype lug down like a naturally aspirated diesel or a much bigger turbocharged engine.

HYBRID

No wonder Volvo expects the 5.5-litre "hybrid blown" engine to take over from its 6.7-litre FL7 unit — road trials of the test engine have been carried out in an FL7 rather than an FL6 chassis; the FL7 cab's wider engine cover also makes room for the extra bulk of the Roots blower.

Mounted high up on the right-hand side of the TD63 engine, the compact intermeshing-lobe compressor weighs 10kg and is said to absorb a modest 5kW peak power. It is made by the Swedish company Opcon, though some Japanese blowers have also been tried.

The whole installation, including pipes — and allowing for the bigger turbocharger — brings a weight penalty of some 20kg, says Gobert, which is insignificant when compared with the 130kg difference in weight between Volvo's 5.5 and 6.7-litre engines.

The supercharger is driven through a magnetic clutch which, as the engine gains speed and the blower's useful work is done, is automatically disengaged at 1,650rpm by an electronic engine speed sensor.

As the revs fall and the inertia of the big turbo's rotor takes its toll, the drive clutch slips into engagement again at 1,500rpm. A non-return valve where the mechanical blower's delivery line meets the input to the turbo prevents back-flow through the supercharger when it is not being driven.

There are emission as well as performance benefits. The supercharger is not needed for 91/542/EEC Euro-1 or even Euro-2 compliance, but it is claimed to eliminate start-up cold smoke and to cut drastically the gaseous hydrocarbons which give diesel exhaust its characteristic smell.

BENEFITS

Those emission benefits add further to the system's appeal for urban delivery vehicles and, like MAN's technique for buses of tapping compressed air off the brake system to augment induction air, could make HC-reducing catalytic aftertreatments unnecessary.

The hybrid blown diesel's maximum efficiency is unaffected: it remains at 42%. But due to the supercharger the efficiency rating at full load is very high, even at extremely low engine speeds.

The hybrid-blown Penta marine engine has been in production for two years but the system is a long way from being introduced in Volvo trucks, says product planning manager Anders Johannesson.

He says the concept is unlikely to be applied to bigger-capacity Volvo diesels because the size of the Roots blowers needed would make them too bulky for easy installation, but as emission laws tighten up and fuel costs continue to rise, more CV manufacturers may come to regard superchargers and turbochargers as natural allies.

11 by Alan Bunting