EURO-6 AFTER TREATMENT How does Euro-6 work Thinking inside the

Page 29

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

box In the third of our series looking at Euro-6 technology, our focus shifts to the aftertreatment system and the chassis Words: David Wilcox Euro-6 engines cannot meet Euro-6 emission limits. The most sophisticated fuel-injection, turbocharging and combustion management can do only half the job; the rest is down to a chemistry set, otherwise known as the exhaust after-treatment system. It works in closely controlled partnership with the engine and is far more complex than today's SCR systems or diesel particulate filters.

What's in the box?

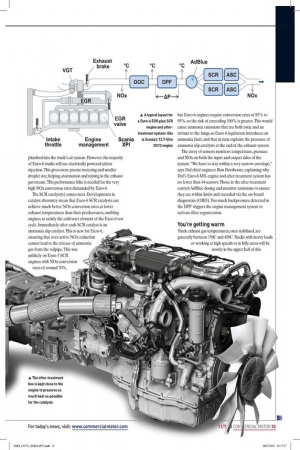

The stainless-steel after-treatment box — which must still function as a silencer — contains several catalysts, a diesel particulate filter (DPF), an AdBlue injector and a multitude of sensors controlling this whole miniature chemical plant. The running order is determined by the chemical processes and prioritisation of catalysts that need most heat and so must come nearest to the engine. Most systems feature a single large DPF but it will be common to have twin SCR catalysts, plumbed in parallel. Design objectives are catalyst performance, minimisation of backpressure and compact size.

The first stage is the diesel oxidation catalyst (DOC), followed by the DPF, also with a catalytic coating. The introduction of a particulate count limit for Euro-6 (as well as the usual particulate mass limit) means that the DPF must be a rigorous wall-flow type, with the exhaust gas needing to pass through the substrate's porous walls, leaving behind the tiniest of particles. The DPF is located where it is easily extracted for routine ash removal.

Then comes the AdBlue injection and mixing stage. The dosing unit is likely to be integrated into the aftertreatment box, together with the injector. The supply unit (pump) is either on the chassis or integrated with the AdBlue tank. Most Euro-4 and -5 AdBlue systems use compressed air to power the injection and so are plumbed into the truck's air system. However, the majority of Euro-6 trucks will use electrically powered airless injection. This gives more precise metering and smaller droplet size, helping atomisation and mixing in the exhaust gas stream. This performance hike is needed for the very high NOx conversion rates demanded by Euro-6.

The SCR catalyst(s) comes next. Developments in catalyst chemistry mean that Euro-6 SCR catalysts can achieve much better NOx conversion rates at lower exhaust temperatures than their predecessors, enabling engines to satisfy the cold start element of the Euro-6 test cycle Immediately after each SCR catalyst is an ammonia slip catalyst. This is new for Euro-6, ensuring that over-active NOx reduction cannot lead to the release of ammonia gas from the tailpipe. This was unlikely on Euro-5 SCR engines with NOx conversion rates of around 70%, but Euro-6 engines require conversion rates of 85% to 95%, so the risk of exceeding 100% is greater. This would cause ammonia emissions that are both toxic and an irritant to the lungs, so Euro-6 legislation introduces an ammonia limit, and that in turn explains the presence of ammonia slip catalysts at the end of the exhaust system.

The array of sensors monitors temperature, pressure and NOx on both the input and output sides of the system. "We have to stay within a very narrow envelope," says Daf chief engineer Ron Borsboom, explaining why Daf's Euro-6 MX engine and after-treatment system has no fewer than 44 sensors. Those in the after-treatment control AdBlue dosing and monitor emissions to ensure they are within limits and recorded via the on-board diagnostics (OBD). Too much backpressure detected in the DPF triggers the engine management system to activate filter regeneration.

You're getting warm Truck exhaust gas temperatures, once stabilised, are generally between 150C and 450C. Trucks with heavy loads or working at high speeds or in hilly areas will be mostly in the upper half of this temperature range; those with low average engine loads will be towards the lower end. Even the latest SCR catalysts need exhaust temperatures of at least 250C to 275C to hit the high NOx conversion rate needed for Euro-6, explaining why thermal management of the after-treatment system is so important.

The after-treatment box is located as close as possible to the engine, and the pipe from exhaust manifold and the box itself are both insulated. Preserving as much heat as possible allows the SCR system to start working quickly and continue for longer if engine load diminishes. Accelerating the switch from EGR to SCR after a cold start helps fuel consumption.

Keeping the DPF warm is just as important. Provided the exhaust temperature is usually above 250C, the soot in the DPF will bum off more quickly than it is being deposited, so the DPF stays soot-free — described as passive regeneration. If temperatures are below this level for extended periods, the DPF will accumulate soot and require active regeneration to trigger a temperature spike, and that entails burning extra fuel (CM 16 May). How often this occurs depends largely on the duty cycle. According to Georg Weiberg, head of engineering at Daimler Trucks, once a week is probably a typical average for the 12.8-litre 0M471 engine in a Euro-6 Mercedes-Benz Actros.

Thermal management has implications for operators who like to specify powerful engines even if their trucks' duty cycles don't demand it. The risk they run at Euro-6 is that low engine loads could mean that the exhaust stays too cool, triggering frequent active regeneration of the DPF and/or a fuel-hungry NOx-reduction strategy. Choosing a power rating aligned more closely to engine loads should keep the after-treatment system warmer, reducing the risk of using extra fuel simply to raise exhaust temperature.

Weighty decisions The size of the after-treatment box is geared to the engine's swept volume; one for a typical 13-litre engine is around 750mm x 650mm x 700mm and weighs 125kg to 150kg, accounting for much of the extra weight of Euro-6 trucks.

Most Euro-6s also have to carry the additional weight of an EGR system and its cooler. And if they have an EGR cooler, it is likely that their radiator and cooling system is bigger at Euro-6 to help dissipate the extra heat. All that EGR kit adds up to about 40kg on a tractor, according to Scania. Of course, today's EGR trucks from MAN and Scania already bear the weight of an EGR kit, but they will also carry the additional burden of an SCR system and AdBlue tank at Euro-6.

Most of this extra weight is on a truck's steer axle. This has repercussions for operations where the diminishing-load scenario already poses a challenge to front-axle loads, so it pays to explore alternative axle and tyre options for Euro-6. Daf addresses this by up-rating the plated weight of its standard front axle and two-leaf suspension from 7.5 to 8 tonnes on Euro-6 tractors. Simultaneously, tyre fitment goes from 295/80 R 22.5 to 315/70 R 22.5, raising the tyres' axle capacity from 7.1 to 7.5 tonnes. Although this gives more tolerance for front axle loadings, it increases kerb weight by 45kg on a 6x2 tractor because the wider tyres are heavier and need 9-inch rather than 8.25-inch rims.

The message from truck manufacturers is that weightsensitive operators have the opportunity to off-set Euro-6's weight penalty, but that may entail tailoring the specification by combing the option list for lightweight alternatives. It may even mean downsizing the engine (CM 30 May).

Package deals Euro-6 has meant wholesale redesigns for some trucks, perhaps new cabs or re-shaping the floor panel to clear a bulkier engine or radiator. Daf has redesigned its chassis, flaring out the main rails at the front to suit a wider radiator. Accommodating the large after-treatment box has prompted some truck manufacturers to re-think how they package components on the chassis to preserve space for big fuel tanks. This provides another opportunity for operators to minimise the impact of Euro-6 on their businesses, with both Daf and Volvo, for example, pointing out that customers now have more choice about chassis layout. Take battery location, for example. You can have the batteries on a Euro-6 Daf tractor in one of four positions: on the right-hand side of the chassis as usual; between the main frame members at the rear; on the catwalk behind the cab; or stacked vertically in a spacesaving arrangement on the chassis side. Daf also expects more UK customers to choose its lightweight mid-lift axle with 17.5-inch wheels on Euro-6 three-axle tractors, in order to recover space and weight lost to the aftertreatment box.

Among the more difficult Euro-6 installations are 8x4 chassis, where there may be insufficient space for an after-treatment box where the silencer would normally be found between axles one and two. On its new Arocs 8x4 tipper chassis, Mercedes locates the box between axles two and three, fed by a long insulated pipe from the exhaust manifold.

Euro-6 trucks using both EGR and SCR will consume less AdBlue than their Euro-5 equivalents. The rate will be 2% to 3.5% of fuel consumption, compared with an average of 5% at Euro-5.

The exception to this will be Volvos with Euro-6 D11K and D13K engines (and the Renault equivalents, DTI 11 and DTI 13) where de-NOx work is heavily skewed towards SCR rather than EGR (their rate is forecast to be 6% of fuel consumption). You can expect a consumption rate of 6% to 8% for SCR-only engines from Iveco and Scania.

Consequently, it pays to scrutinise AdBlue tank capacities for Euro-6, particularly if weight is critical. At 1.09kg/litre,AdBlue is 30% heavier than diesel. As well as offering a wider range of capacities, some manufacturers have moved the AdBlue tank away from the chassis side to free up more space for fuel tanks. Volvo and Daf both put the AdBlue tank on Euro-6 tractors on top of the chassis, near the cab bulkhead. Scania has some new low-profile AdBlue tanks, hidden on the inside of the chassis frame. • • Next time, we look at the routine maintenance implications of Euro-6, focusing in particular on oil, fuel and keeping the after-treatment system in tip-top condition.