REDUCING DEAD WEIGHT IN TILT WAGONS

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

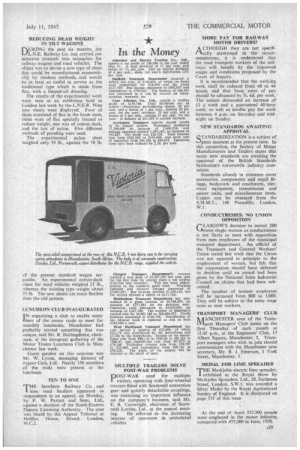

riURING the past six months, the Railway Co. has carried, out intensive research into tarpaulins for railway wagons and road vehicles. The object was to devise a new type of sheetthat could be manufactured economically by modern methods, and would be at least as useful in service as the traditional type which is made from flax, with a linseed-oil dressing.

The results of the experimental work were seen at an exhibition held in London last week by the L.N.E.R. Nine new sheets were displayed. Four of them consisted of flax in the loom state, three were of flax specially treated to reduce weight, one was of cotton duck, and the last of nylon. Five different methods of proofing were used.

The experimental nylon sheet weighed only 39 lb., against the 70 lb.

of the present standard wagon tarpaulin. An experimental cotton-duck :.beet for road vehicles weighed 25 lb., whereas the existing type weighs about 37 lb. The new sheets are more flexible than the old pattern.