CONSTRUCTIONAL JFEA UR IN

Page 116

Page 117

If you've noticed an error in this article please click here to report it so we can fix it.

• US-BODY

UILDING

Notes Upon the Main Factors in the Design of the Up-to-date Service-bus Body

THE average bus body is of considerable length and if it be clipped securely to a chassis which, owing to roadsurface inequalities, undergoes distortions, small although they may be, it follows that strains must be set up in the body framework. For this reason some builders consider that the forward-control cab should be mounted independently of the main saloon, with a gap or flexible connection at the front bulkhead and canopy rail.

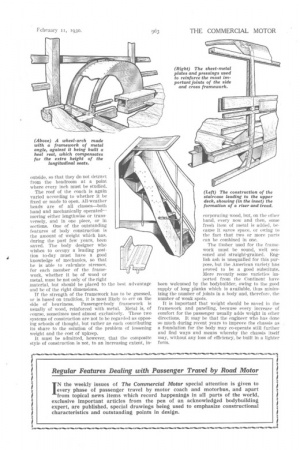

The use of sheet metal for the reinforcement of the more important junctions of the side and cross framework continues to form one of the most scientific aspects of body construction. Neat pressings are also employed to strengthen almost any joint where formerly a malleable cast or forged corner plate was used. In this way both weight and space are saved.

The chassis with the low load-line is, for an indefinite period, likely to continue in favour. Consequently, the obstruction offered by the wheelarch must be regarded as a feature which cannot be ignored, but its shape and position must be carefully studied, in order that it shall affect, to the least extent, the seating plan and the comfort of the passengers.

Even if smaller wheels were adopted, the wheel-arch would still remain, because floor level is so important when overall height is a controlling factor. With allowances, for spring deflection cut down to a minimum, the bodybuilder is then anxious that the structure of the arch

itself shall be a model of compactness, so that the crown of the arch does not unduly influence the seat-cushion level.

Here, again, metal framework and panelling are of value. If the longitudinal seats must be raised above the others, a neat heel rest is built up, locally raising the floor to agree with the extra height of the seat.

The front bulkhead of a rearentrance bus, unpierced by a doorway, is a simple flat structure which lends itself to scientific cross-bracing. When forming part of a double-decker, the detail design of its ventilators decides to a considerable extent the efficiency of the ventilating scheme of the lower saloon.

Much ingenuity is expended on the design of the staircase, and with larger platforms and sunk gangways in the upper saloon, both ascent and descent are facilitated.

What a wealth of variation is there in roof construction The roof of the single-decker may consist of plywood and alnininium panels, or it may be covered with boards so narrow that an extremely sharp curve may be made.

The roof of the lower saloon of the double-decker may be a plainly cambered doubl eboard ed arrangement, with waterproof material between. On the other hand, it may be specially designed to provide sunk gangways for the upper saloon. Then the roof of the upper saloon is an example of how construction may be simplified by the use of metal, both for the cross-ribs and for the cover, the ribs being placed outside, so that they do not detract from the headroom at a point where every inch must be studied.

The roof of the coach is again varied according to whether it be fixed or made to open. All-weather heads are of all classes—both hand and mechanically operated-moving either lengthwise or transversely, and in one piece, or in sections. One of the outstanding features of body construction is the amount of weight which has, during the past few years, been saved. The body designer who wishes to occupy a leading position to-day must have a good knowledge of mechanics, so that he is able to calculate stresses, for each member of the framework, whether it be of wood or metal, must be not only of the right material, but should be placed to the best advantage and be of the right dimensions.

If the strength of the framework has to be guessed, or is based on tradition, it is most likely to err on the side of heaviness. Passenger-body framework is usually of wood, reinforced with metal. Metal is, of course, sometimes used almost exclusively. These two systems of construction are not to be regarded as opposing schools of thought, but rather as each contributing its share to the solution of the problem of lessening weight and the cost of upkeep.

It must be admitted, however, that the composite style of construction is not, to an increasing extent, in corporating,wood, but, on the other hand, every now and then, some fresh item of metal is added, because it saves space, or owing to the fact that two or more parts can be combined in one.

The timber used for the framework must be sound, well seasoned and straight-grained. English ash is unequalled for this purpose, but the American variety has proved to be a good substitute. More recently some varieties imported from the Continent have been welcomed by tile bodybuilder, owing to the good supply of long planks which is available, thus minimizing the number of joints in a body and, therefore, the number of weak spots.

It is important that weight should be saved in the framework and panelling, because every increase of comfort for the passenger usually adds weight in other directions. It may be that the engineer who has done so much during recent years to improve the chassis as a foundation for the body may co-operate still further and find ways and means whereby the chassis itself may, without any loss of efficiency, be built in a lighter form.