Bimode trolleybuses prove their worth

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

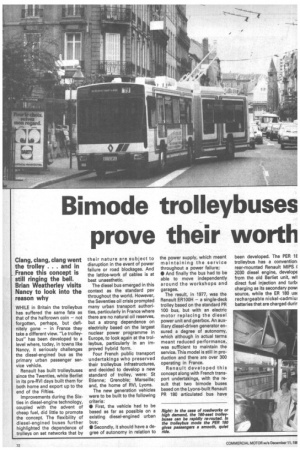

Clang, clang, clang went the trolley . . . and in France this concept is still ringing the bell. Brian Weatherley visits Nancy to look into the reason why

WHILE in Britain the trolleybus has suffered the same fate as that of the halfcrown coin — not forgotten, perhaps, but definitely gone — in France they take a different view. "Le trolleybus" has been developed to a level where, today, in towns like Nancy, it seriously challenges the diesel-engined bus as the primary urban passenger service vehicle.

Renault has built trolleybuses since the Twenties, while Berliet in its pre-RVI days built them for both home and export up to the end of the Fifties.

Improvements during the Sixties in diesel-engine technology, coupled with the advent of cheap fuel, did little to promote the concept. The flexibility of diesel-engined buses further highlighted the dependence of trolleys on set networks that by their nature are subject to disruption in the event of power failure or road blockages. And the lattice-work of cables is at best unaesthetic.

The diesel bus emerged in this context as the standard psv throughout the world. However, the Seventies oil crisis prompted many urban transport authorities, particularly in France where there are no natural oil reserves, but a strong dependence on electricity based on the largest nuclear power programme in Europe, to look again at the trolleybus, particularly in an improved hybrid form.

Four French public transport undertakings who preserved their trolleybus infrastructures, and decided to develop a new standard of trolley, were: St Etienne; Grenoble; Marseille; and, the home of RVI, Lyons.

The new generation vehicles were to be built to the following criteria: • First, the vehicle had to be based as far as possible on a existing diesel-engined urban bus; • Secondly, it should have a degree of autonomy in relation to the power supply, which meant maintaining the service throughout a power failure; • And finally the bus had to be able to move independently around the workshops and garages.

The result, in 1977, was the Renault ER100H — a single-deck trolley based on the standard PR 100 bus, but with an electric motor replacing the diesel power unit and gearbox. An auxiliary diesel-driven generator ensured a degree of autonomy, which although in actual terms meant reduced performance, was sufficient to maintain the service. This model is still in production and there are over 300 operating in France.

Renault developed this concept along with French transport undertakings, with the result that two bimode buses based on the Lyons-built Renault PR 180 articulated bus have been developed. The PER 18 trolleybus has a convention. rear-mounted Renault MIPS ( 2030 diesel engine, develope from the old Berliet unit, wil direct fuel injection and turbl charging as its secondary pow source, while the ER 180 USE rechargeable nickel-cadmiui batteries that are charged durir o mal trolleybus operation and n ble it to operate off the netio Ithough the ER 180 has a h rter range than its diesel 3 nterpart, it has the advanig of remaining in electric ri e throughout. The ideal p ration for the vehicle is in an

astructure that has small (3k ) gaps in the network that reiunsuitable for electrification.

Anance, however, rather than erformance, has been the lajor.,deciding factor for both a icles. Renault is not paying )r. he development of a vehicle nl ss its future is guaranteed. h ER 180 has yet to be icipted by a local authority, and le development grant from the iscard d'Estaing Government 3s1 not been renewed by the repent administration. So the oject has not been developed rther.

The PER 180, however, has a ighter future, particularly in jht of the recent inauguration the Nancy trolleybus network hich is currently running 33 ER 180s with a further 15 to be ,livered at the beginning of I83. The £6m contract is but a nail part of the £30m grant given to the District Urbain De Nancy by the French Government to build a trolleybus network which began operating two weeks ago. As a result of the order, Renault is now claiming to be the first company in the world to enter full-scale production of a truly bimodal trolleybus.

I visited Nancy, 180 miles east of Paris, to see the system at first hand. The town's population of 270,000 live in a relatively large area including hills. The trolleybase grid spreads from the centre of the town for 30 kilometres into outlying districts.

Most of the main thoroughfares are equipped with an electrical supply; the six metrehigh cables carry a potential of 750 volts, generated by a central sub-station in the town, with additional 1,000 kilowatt substations distributed along the various routes. Each cable run is divided into isolated sections of one and a half kilometres.

To enter the network, each trolleybus must join the grid at one of 12 starting points. The bus stops beneath the wire while the driver raises the fibreglass trolleybus poles by means of a dash-mounted control. The articulated electrical connections fix onto the wire automatically.

The 186kW (250hp) electric motor, mounted transversely under the trailer on the left-hand side in front of the rear axle, then engages and drives the rear two axles via a transfer gearbox situated halfway down the driveshaft between the second and third axles.

With the electric motor engaged, the diesel driveline is disconnected. (Renault has adopted the principle of driven mid and third axles as standard on all its articulated buses, citing greater stability and road holding as the reason.) The whole process of joining the trolleybus grid takes roughly one minute.

The electrical equipment on the PER 180 is produced by two companies, Alsthom Atlantique and Traction CEM Oerlikon (TCO), which both have factories in Nancy. The PER 180 artic buses are built at the Lyons Venissieux plant and are then transported to Nancy where the electrical equipment is fitted before the trolleybus enters service.

The PER 180 has a sophisticated electronic controller which incorporates a freoncooled current "chopper" that halves the energy required by the motor for accelerating by recuperating a significant proportion of the energy used in vehicle braking.

Although controlled by the Urban district of Nancy, the network is run by the Paris-based transport consortium, La Compagnie Generale Francaise de Transports et d'Entreprises — CGFTE.

As part of its £30m grant, Nancy has gained a brand new computer-run traffic control centre, which not only monitors traffic flow in central Nancy and deals with trolleybus routeing, but is also connected to traffic signals. This allows it to give priority at light controlled junctions to passenger service vehicles. There are well defined bus lanes and other road users do not suffer.

The computer centre also controls waiting and stop-over times for the vehicles; if a blockage occurs services are instantly rescheduled. Like many Continental systems, the Nancy trolleybus network is geared to wards self-service tickets purchased in advance of the journey, with ticket discounts offered on multi-journey cards over single trips.

The diesel flexibility of the bimode PER 180 gives the Nancy planners the ability to adjust services to cope with shifts in demand without depending on the overhead network. They can also extend services to outlying districts which they cannot afford to include in the trolleybus network.

When I travelled in the Renault trolleybus, my overriding impression was one of quiet. Even with the diesel engine running, the noise levels are very low owing to the well insulated, rearmounted engine. I also appreciated the complete absence of gear changing, which leads to a smooth ride even for standing passengers.

For diesel operation the PER 180 reverts back to a standard ZF type 4 HP 500 automatic gearbox.

Although firm and a trifle narrow, the seats offer good support, at least for those of the 160 passengers who can get one, and the overall ride is excellent. Renault's mixed air and spring suspension on the PER 180 integral chassis gives a soft but by no means unpleasant ride even over the classic French cobbled streets.

Braking in the diesel mode is via the standard engine cornpressor/airbrake system, while in the trolleybus mode an electric compressor is switched in. Fully laden, the trolleybus has little problem keeping up with the town traffic, while its hillclimbing ability on the outskirts of Nancy seems equal to that of a conventional bus but with the advantage of being quieter. Maximum gradient for the vehicle is 13 per cent.

As well as the original £30m grant towards the scheme which covered research and development, vehicle purchase, infrastructure, and management, the Nancy district has received a further E8m in direct grant to help establish the scheme, and a sum of £2m to aid running costs during the next three years.

Unfortunately, the recent opening of the network has meant that current cost data has yet to be accumulated, but, according to Renault engineers, the cost advantage of the bimode PER 180 is expected to increase in line with the ever ascending rise in diesel fuel prices.

Basing their assumptions on a general figure of five francs (0.44p), that being the current averaged cost of a litre of dery in France, the PER 180 is no more expensive to run than its conventional stablemate, the PR 180. However, as is almost inevitable, when diesel prices go above that figure, the PER will become the more cost effective. As the PER 180 only uses its diesel engine for half of its operating time, there is also a saving on engine wear.

Nancy has a total bus fleet of 200 vehicles, including the 48 new trolleybuses, but by 1986 it aims to have a total of 80 bimode trolleybuses in operation. Purchase price for the PER 180 is almost double that of a conventional diesel-powered artic bus, but Nancy is looking for a target life of 18 years from its PER 180s, compared to a significantly shorter period for normal buses. In some cases the electric motor can be reclaimed.

Other towns in France are interested in the Nancy scheme, and eight PER 180 trolleybuses will be joining the St Etienne trolleybus network in 1983. For some months now a modified PER 180 has been on trial with the Seattle Transit Authority in the United States.

Whether schemes like Nancy's will ever influence transport thinking on this side of the Channel remains very much a question of funding. Although the two countries are separated by a mere 22 miles of salt water, politically the gap between British and the French transport subsidies is far wider. The Nancy bimode system is impressive, and few British public transport aurhorities would turn down a £30m grant to develop a new urban transport network with or without trolleybuses.

However, where would the money come from?

Indeed, how could we evaluate a trolley system? We have no infrastructure left. And is a British manufacturer prepared to build a trolley? MCW has said it would be will ing to build a vehicle based on a metrobus, but it has not so far produced a prototype in either dual or single mode.

Renault, however, remains firmly committed to the principle and donates £5m annually to truck and bus research.

An EEC commission was established last year involving

the UK, West Germany, France, Denmark, Finland, Belgium, Italy and Switzerland to evaluate dualmode trolleybus technology. Once the technical appraisal has been completed, a practical trial is to take place based on an existing diesel bus route in Liege, using 20 articulated bimode trolleybuses. 11 must be assumed that EEC money will be available to set up schemes in the Community should the trials provs successful.

Ironically, the one source cr interest in Britain has come frorr West Yorkshire PTE, whict operated our last trolleybus ser vice, in Bradford, until the earl) Seventies. At a transport sym posium earlier this year (CA, Passenger News April 10, 1982) WYPTE strategic planning man ager, Dr Michael Harrison, spok( of the advantages of trolleybu; operation. He cited longer lif( and reduced maintenance though, surprisingly, in networl studies in Bradford the bimod( vehicle was found to be econo mically inferior to the singl; mode-only trolleybus.

Should the trolleybus ever re turn to the UK in any form, it wil not be without extensive fund ing on a national scale. In thi context of the current politics attitudes, this is unlikely. Politi cally, large grants mean greate public involvement — a doctrinl currently hotly debated by botl major parties with all the ensu ing dogma and little sign of lighi However, the possibility doe exist that the Common Marks

could give capital grants fc intrastructures. But that woul,

still leave the problem of the cui rently high costs to industry c energy.

Nancy's approach to transpo gives an indication of how we state-funded, environmentall acceptable transport can su; ceed. In the UK, is it wise fc diesel bus manufacturers to re: easy? My guess is yes, for if th bimode trolleybus is the vehicl of the future, I cannot see it b; ing the immediate future. But may have to join "Le club c trolleybus" at a later date.