CLEANSING SERVICE GROUP

Page 95

Page 96

Page 99

If you've noticed an error in this article please click here to report it so we can fix it.

by Ron Cater

WHEN I visited the Cleansing Service Group at Botley. Hampshire, I was told by Mr H. W. Mould, director and general manager: "Many of the proprietary gully and cesspit emptying vehicles are now so complicated that a technician is needed to operate them". But his company's aim when specifying new vehicles is simplicity.

The firm, started by Mr E. A. Hart in 1934 with a very second-hand Dennis bought for £5, has grown to a 156-vehicle fleet; it is all engaged on waste disposal of one sort or another. And such is the current growth rate of the business that of four new vehicles always in the preparation stages, three go into the fleet as extra vehicles and only one as a replacement.

About 95 per cent of the fleet has been employed with licences which do not tie vehicles to local authorities and so that proportion has been eligible for MoT testing. This has increased the load on the vehicle workshops but not sufficiently to cause problems. The shops are loaded on the basis of flat time working plus four hours on Saturday morning when the shop is cleared up in preparation for the next week's activities. This system leaves the whole available overtime kitty ready to cope with any emergency that may arise and prevents fitters becoming stale and turning out shoddy work. The labour force in the shop works shifts so that the shops are operating from 6 am until 10 pm. three men being on duty during each of the out-of-normal hour periods.

Apart from very specialized equipment

The gully and cesspit empties are kept strictly functional the trend being to use Bedford TK chassis for the 1000gal units and Dodge K1050 chassis for the 15009a1 units.

such as the Load Lugger and Dempster units used by the company, most of the building is carried out by a subsidiary. Simmons Engineering (Southampton) Ltd. whose most adequately equipped factory is situated only a mile or so from the head office. All the tanks for the cesspit and gully emptiers are made by Simmons: so are the skips for use with the Load Luggers. Simmons is a self-supporting subsidiary which has to submit competitive quotations for jobs put to tender by the parent firm. Simmons also accepts all sorts of work from outside firms and manufactures a substantial caravan transporting semitrailer, mostly to special order.

Much of the design and standardization of the gully and cesspit tankers used has been evolved over many years of experience. Note is taken of comments by drivers about the jobs they have to do: in fact, quite often alterations are made to the vehicles to overcome the men's criticisms. As Mr A. E. Case. the group fleet engineer, put it: "They are doing the job and we try to make their job as simple as possible by taking note of their comments or complaints, always provided they are neither stupid nor frivolous." Examples of the way things have developed are the tanker sub-frames, the hose carriers, the uplift pipework in the tanks and the positioning of the rear outlets. The sub-frames are fabricated from rolled-steel channel and boxed in on the inside. Tank cradles are all of the same radius so that tanks can be swapped over without the need to disturb the sub-frame. The sub-frame has continuous runners which sit on the top flanges of the chassis. This overcomes the problems of having fixed positions for securing U-bolts should a frame be changed to a different chassis, a job that crops up in the life of every tank because each one outlasts at least two chassis. Also, by retaining the same tank radius for the two capacities of tanks used (1000 and 1500gal) it is possible to utilize common rear doors and dished ends—the units bought in.

Many styles of fastening have been evolved and experimented with over the years for securing tanks to the bolsters, and the one used now has proved completely successful for the first time. It comprises a flat lug and tension bolt welded to the shell of the tank adjacent to the securing eye on the bolster. It is claimed to have overcome the problems of tanks working round in the cradles and sliding forwards or backwards and upsetting the connections between the exhauster /blower units. The fabricated sub-frame is carried forward of the tank so that the auxiliary pumping engine and blower unit can be mounted integrally with the tank and be lifted off bodily should a change of chassis become necessary in a hurry. The exhausters are piped through a cyclonic filter developed by the firm after a considerable amount of unsatisfactory

experience with the proprietary units available which, it appears, filter too well and become blocked so quickly that they are a nuisance. in service. Also, drivers tend to overlook the fact that a by-pass valve is operating and often the filters are completely inoperative for days on end. The Cleansing Service filter has no element, just radial baffles, and it embodies a 2in.-diameter drain plug through which it can be drained and hosed out if required. Proof of its efficiency is the extensive life between overhaul of the compressor units.

The compressors used are by Hammond Pump and Equipment Co Ltd and by Reavell and Co. The Hammond units were fitted originally with a recirculating lubrication system but the oil was found to be quickly contaminated by the cesspit gases and so to lose its lubricating qualities. The systems were converted to the total-loss type and no further trouble has occurred.

Single-cylinder Petter AVA I diesel engines are used to drive the compressor /exhausters, the reason given for accepting what seems to be a high unladen weight penalty is the vast saving in fuel costs. This amounts to some £.4500 a year through the use of rebated fuel. To assist starting during cold weather the drive shafts from the engines are passed through a centrifugal clutch which throws in at 550 to 600 rpm. The average amount of fuel used by these engines is about 0.75gal a day.

The hose carriers on the vehicles are simply a frame into which the hoses are laid. All sorts of boxes have been tried but this simple device has proved by far the most successful and simple to use. The positioning of the rear outlet of the tanks at first seems strange—it points to the offside of the vehicle. This has been done to enable the drivers to see what is going on when they are spreading semi-digested sludge, picked up from filter beds on sewage farms, onto agricultural land. Farmers, it seems, are most particular as to how this material is distributed and with the pipe in the current position the driver can watch the progress in his mirror.

The tanks are always vacuum-loaded, that is to say the vessel is emptied by the exhauster and the load enters the vessel to fill the vacuum. The pick-up pipe goes into the bottom of the rear door of the tank and is carried on upwards, terminating in an open end beneath a dome in the top of the tank. This ensures that the exhauster is never sucking through the load once the pick up is completed and, of course, the load cannot run back down the pipe. The system is claimed to speed loading quite considerably and in fact the vehicles can uplift 1000gal of water in just about four minutes. A float-operated cut-off valve prevents over-filling of the tank and contamination of the exhauster with water and/or sludge.

Much of the company's business has moved from domestic waste disposal to disposal of industrial waste. In many cases this means disposing of corrosives, poisons and explosive materials, and so a number of vehicles constructed from stainless steel or with epoxy-resin lined tanks and raised to petroleum transport regulation standards are employed. Among the special arrangements on these vehicles are electronic load-probes which permit tanks to be vacuum-loaded without the danger of over-filling and spillage. In order to permit cargoes of different gravities to be sensed by the probes, the firm is experimenting with adjustable units which can be preset to read. say, 500 gallons in a 1000gal tank and also with a test circuit to ascertain the probes are operating correctly.

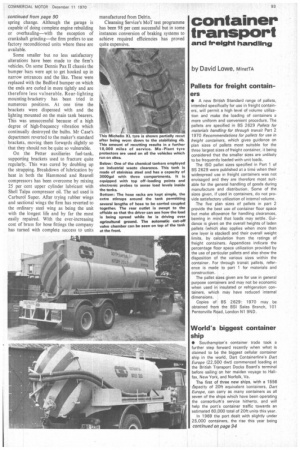

Below: Boxed-in runners are used for the tank mountings so that U-bolts can be fitted at any point along the chassis. The runners are extended forward to accommodate the auxiliary pumping unit as well. The Cleansing Service Group's cyclonic filter can be seen between the fuel tank and the rear wheel_ Tension bolts are welded to the tank shell instead of having the more usual strap mounting.

Bottom: A scene in the shops of Simmons Engineering—several tanks are taking shape.

The handling of materials with specific gravities ranging from 0.75 to 1.8 presents a problem when choosing the size of the tanks to be used. The extremes of choice are a small light tank that will carry a high tonnage of high-density liquid or a large tank that will carry a large number of gallons of low-gravity liquids. The Cleansing Service Group. has selected a sprinkling of each and others right in the middle of the range.

Experiments were carried out with glass-reinforced plastics tanks, but the results were not very good. This was because flexing of the glass-fibre shell caused the liner with which the tanks were equipped to separate from the shell, letting the liquids carried get between shell and liner. But the firm has not given up the idea of using plastics tanks and it is waiting for a new unit to be delivered with which it will undertake further evaluation of the type.

About 80 per cent of the tyres used in the fleet are Michelin. Michelin X are used on the front wheels while on the rear of those vehicles likely to have to operate in site conditions XL tyres are fitted. These are currently giving about 35,000 miles achieved by running them down to the stabilizing bar and then recutting this at approximately 15,000 miles to give at least a further 18,000 miles life. Another feature of the company's tyre policy is the use of Mo-Plant tyre protectors which has reduced the incidence of punctures and other penetration damage by 60 per cent.

Nearly 20 per cent of the general servicing and engineering work is taken account of by vehicles based away from the depots and this is done by selected garages on a contract basis.

Systems used in the main workshops are aimed at quick turnround, for instance spring U-bolts are cut off with acetylene if they prove in the least stubborn during a spring change. Although the garage is capable of doing complete engine rebuilding or overhauling—with the exception of crankshaft grinding—the firm prefers to use factory reconditioned units where these are available.

Some smaller but no less satisfactory alterations have been made to the firm's vehicles. On some Dennis Pax IT chassis the bumper bars were apt to get hooked up in narrow entrances and the like. These were replaced with the Bedford bumper on which the ends are curled in more tightly and are therefore less vulnerable. Rear-lighting mounting-bracketry has been tried in numerous positions. At one time the brackets were dispensed with and the lighting mounted on the main tank bearers. This was unsuccessful because of a high degree of high-frequency vibration which continually destroyed the bulbs. Mr Case's department reverted to the maker's standard brackets, moving them forwards slightly so that they should not be quite so vulnerable.

On the Petter auxiliaries fuel-tank, supporting brackets used to fracture quite regularly. This was cured by doubling up the strapping. Breakdown of lubrication by heat in both the Hammond and Reavell compressors has been overcome by mixing 25 per cent upper cylinder lubricant with Shell Talpa compressor oil. The ucl used is Carburoi Super. After trying rubber wings and sectional wings the firm has reverted to the ordinary steel wing as being the unit with the longest life and by far the most easily repaired. With the ever-increasing cost of brass for hose fittings the company has turned with complete success to units manufactured from Delrin.

Cleansing Service's MoT test programme has been 98 per cent successful but in some instances conversion of braking systems to achieve required efficiencies has proved quite expensive.

This Michelin XL tyre is shown partially recut after being worn down to the stabilizing rib. This amount of recutting reaults in a further 18,000 miles of service. Mo-Plant tyre protectors are used on all the vehicles which run on sites.

Below: One of the chemical tankers employed on industrial waste clearance. This tank is made of stainless steel and has a capacity of 3000gal with three compartments. It is equipped with top off-loading points and electronic probes to sense load levels inside the tanks.

Bottom: The hose racks are kept simple, the extra stirrups around the tank permitting several lengths of hose to be carried coupled together. The rear outlet is swept to the offside so that the driver can see how the load is being spread while he is driving over agricultural ground. The automatic cut-off valve chamber can be seen on top of the tank at the front