INLAND CONTAINERBASES AIM TO CUT HANDLING COSTS

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

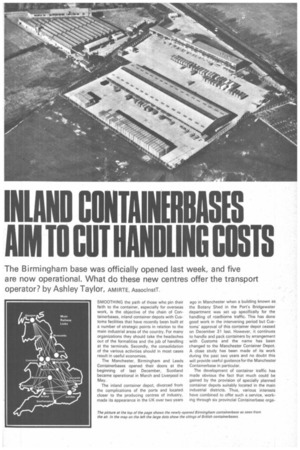

The Birmingham base was officially opened last week, and five are now operational. What do these new centres offer the transport operator? by Ashley Taylor, AMIRTE, AssocInsa.

SMOOTHING the path of those who pin their faith to the container, especially for overseas work, is the objective of the chain of Containerbases, inland container depots with Customs facilities that have recently been built at a number of strategic points in relation to the main industrial areas of the country. For many organizations they should take the headaches out of the formalities and the job of handling at the terminals. Secondly, the consolidation of the various activities should in most cases result in useful economies.

The Manchester, Birmingham and Leeds Containerbases opened their doors at the beginning of last December, Scotland became operational in March and Liverpool in May.

The inland container depot, divorced from the complications of the ports and located. closer to the producing centres of industry, made its appearance in the UK over two years ago in Manchester when a building known as the Botany Shed in the Port's Bridgewater department was set up specifically for the handling of roadborne traffic. This has done good work in the intervening period but Custom& approval of this container depot ceased on December 31 last. However, it continues to handle and pack containers by arrangement with Customs and the name has been changed to the Manchester Container Depot. A close study has been made ofits work during the past two years and no doubt this will provide useful guidance for-the Manchester Containerbase in particular.

The development of container traffic has made obvious the fact that much could be gained by the provision of specially planned container depots suitably located in the main industrial districts. Thus, various interests have combined to offer such a service, working through six provincial Containerbase orga nizations, each of which is a limited company in its own right. Holdings in these companies are in the hands of groups of interested organizations, the ownership in each being somewhat different. British Railways participate in several and in some cases local dock organizations are among the sponsors.

Containerbase (Liverpool) Ltd., to take one example, is supported by the Mersey Docks and Harbour Board, British Railways, the National Freight Corporation, Associated Container Transportation Ltd., and Overseas Containers Ltd. In Birmingham, Coast Lines Ltd. has a holding, and the NFC has a minority interest in each, as it has in the West of England Freight Terminal Ltd., which is not, of course, a member of the Containerbase Federation Ltd.

This series of companies comprises Containerbase (London East) Ltd., which is located at Orsett, Essex, a few miles from Tilbury, Containerbase (Manchester) Ltd., at Barton Dock Estate (West), Urmston, Lancs., convenient for Manchester Docks and the Trafford Park Industrial Estate, Containerbase (Liverpool) Ltd., at Bootle, on Merseyside, Containerbase (Birmingham North) Ltd., at Perry Barr, Birmingham, handy for M6 and M1 motorways, Containerbase (Leeds) Ltd., accessible for the West Riding, the Humber and M1 /A1, and the Containerbase (Scotland) Ltd., at Coatbridge in the Clyde industrial belt. Each of the foregoing is a member of Containerbase Federation which is responsible for common policy, central buying and national negotiations. All of the bases are operational with the exception of London East.

At each depot provision has been made so that at either the commencement of main container movement, or at its conclusion, facilities are available for checking, documenting, consolidating or distributing the goods. For imported containers (or TIR vehicles) handled during ordinary working hours there will be a £5 minimum charge but the basic figure is £2 8s per revgnue ton of 2,240Ib or 80 cult. High quantity discounts will be offered. Except that the basic figure is £2 4s per ton, containers and vehicles for export will be subject to a similar arrangement. The work that is carried out is purely of a terminal nature, including lifting the container on to or off the transporting vehicle, the transport operators being responsible for all movement to and from the Containerbases.

Customs help

All the bases are new and are purposebuilt. Static and mobile handling equipment suited to the main local traffic has been installed, including everything necessary for the handling of small consignments destined for groupage, as well as the containers themselves. In every case Customs have assisted in evolving the necessary procedure and each base has resident Customs officers. Lancer Boss 2500 and 3500 lifters or MAFI Portalifts will make light work of the containers and the internal handling of consignments will be by pallet.

Standard procedure at the Containerbases for containers arriving from overseas provides first for the movement from the reception section to the unloading area. Off-loading of the various consignments then takes place, a full check being made and any necessary documents being completed. The consignments are then presented for Customs examination, afterwards being prepared fo loading on to the outgoing vehicles. Thi charge that has been quoted earlier cover two days' storage of the cargo in addition t( the day on which unloading takes place When cleared the container is moved from ON unloading section to the delivery park where i can remain for up to three days without extri charge.

In the opposite direction loose cargo i received and checked in, the cost coverim two days storage if necessary, plus the receiv ing day. The various items for export ar. concentrated into container loads and, if re quired, produced for Customs inspection.

Meanwhile the allotted container will hay been swept and transported to the loadin. section, loading then taking place and bein. followed by the checking of the various item and the issuing of the requisite document After this the container is moved forward t the outwards park where, if desired, it can b held for three days without extra charge.

The Containerbases are essentially co-opei ative structures, not in the financial sense bt in the manner in which the various service are concentrated in the different centres so a to give the transport community and its cut tomers the benefits of equipment and facilitie that would otherwise be out of reach for th general run of operators. In most place where it can be carried out the lifting of th containers themselves is quite an expensiv business but this the bases take in their strid( including this process in their standard fees.

While they are basically similar, th different establishments are not all built t one pattern. Nevertheless to describe some thing of Manchester will provide an outline c the accepted layout.

For 18 months the Manchester base ha grown up under the eyes of Mr. J. Thomsor now its manager. The location at Barton Doc Road, on the Barton Dock Estate, is adjacer to M62, is a half-hour run from M6, an stands on the fringe of the great Trafford Par industrial complex. Vehicles enter through th gatehouse at one end of the main administrE tive block, the control office checking the

ocuments and directing each driver to the ppropriate spot on the site. Likewise. outoing units are checked as they depart by way f the exit lane. A high mesh fence encloses le site.

The two-storey administration building ouses the various Containerbase deartments, in addition to this there being xtensive accommodation for on-the-spot rffices for shipping and forwarding organizeions. When I visited Manchester Containerase, Overseas Containers Ltd. in particular, was in full operation. Here information eeded by the parent office is recorded on ape, fed into the transmission system and otomaticallY absorbed into the OCL master omputer in London.

:ompact planning

Altogether the Manchester site covers ome 21 acres so that a tannoy system is a irtual necessity. Closed-circuit television is oing in and a pneumatic tube delivery line for ocuments has been built into the premises !though this system had not commenced working at the time I was there. Careful ■ lanning hat in this way cut to a minimum the leed for staff to indulge in a time-wasting 'um around the area.

A cafeteria, open to all engaged on the 'cation is housed in the main office block and erves some 80 lunches daily in addition to ght refreshments. Security office and first-aid oorn are among other activities housed in this loading.

Across the vehicle park, close by the main bed, is the base office with its control board hat shows the occupancy of the various paces on the site. The shed itself has an area of 56,000 sq.ft., this including in the centre a :ustoms examination cage and a security age. The bank is arranged with the whole of one side devoted to vehicle reception and lispatch with a platform at 4ft height. On the opposite side, where the containers are handlid, the platform height is 4ft 9in.

On the bank the movement of the conignments is handled by Stacatrucs, seven )attery-operated and one working on LPG. Wandering-flex lighting connections are provided at various points particularly to facilitate working inside long containers. There are also points on the bank ready for connection to refrigerated units if required. At a lower level in this section are washrooms with showers.

Manchester, being one of the Containerbases that is rail-connected, receives two trains each morning, one from Tilbury and the other from Harwich and Felixstowe. They commence their return journeys with export containers in the late afternoon. Road vehicles are entering and leaving throughout the day. A Lancer Boss Series 3500 lifting unit is available to deal with 30ft and 40ft containers and a Series 2500 for the 20-footers.

While they perform the actual lifting, movement around the site is carried out by three Tugmasters (for one of which a snow-plough is available, an essential in dealing with the enormous vehicle park). The tractors are accompanied by 16 skeletal trailers, a dozen for the 20ft containers and four for the 30ft and 40ft sizes. The Tugmasters each have automatic gearbox and elevating fifth-wheel. For handling 40ft containers a spreader, itself weighing 3f tons, is employed. Special grid locations are used on the park for refrigerated units that have to stand overnight, there being eight spaces where the vehicle plant can be plugged in.

Security angle

In the special circumstances attached to Containerbases the security angle is of the highest priority. This is a main consideration in the system of interlinked documentation which is also integrated with internal control and accounting. Staff employed on the base are all issued with certificates of identity of which there are two categories. Only specially authorized personnel are permitted in the security sections of the establishment.

Contractors are still at work on sections of the Manchester Containerbase but little remains to be done before Phase I is all complete. Plans are already in being for Phase 11 when such development is justified by the volume of business.