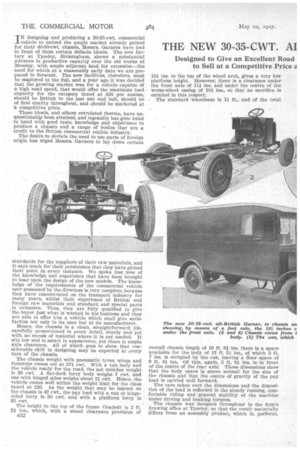

THE NEW 30-35-CWT. Al RITISH GARNER CHASSIS.

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

IN designing and producing a 30-35-cwt. commercial vehicle to extend the ample market already gained for their 40-50-cwt. chassis, Messrs. Garners have had in front of them certain definite ideals. The new factory at Tyseley, Birmingham, shows a substantial advance in productive capacity over the old works at Moseley, with ample adjacent land for extension—the need for which at a reasonably early date we are prepared to forecast. The new facilities, therefore, must be employed to the full, and a year ago it was decided that the growing market was for a vehicle capable of a high road speed, that would offer the maximum load capacity for the category taxed at £26 per annum, should be British to the last nut and bolt, should be of first quality throughout, and should be marketed at

• a competitive price.

These ideals, and others correlated thereto, have unquestionabLy been attained, and ingenuity has gone hand in hand with good taste, knowledge and experience to produce a chassis and a range of bodies that are a credit to the British commercial vehicle industry.

The desire to obviate the need to use parts of foreign origin has urged Messrs. Garners to lay down certain standards for the suppliers of their raw materials, and it says much for their persistence that they have gained their point in every instance. We spoke just now of the knowledge and experience that have been brought to bear upon the design of the new models. The knowledge of the requirements of the commercial vehicle user possessed by the directors is very complete, because they have concentrated on the transport industry for many years, whilst their experience of British and foreign raw materials and standard and special parts is extensive. Thus, they are fully qualified to give the buyer just what is wanted in his business and they are able to offer him a vehicle which shall give satisfaction not only to its user but td its manufacturer.

Hence, the chassis is a clean, straightforward job, carefully proportioned in every detail, sturdy and yet with no excess of material where it is not needed. It sits low and is smart in appearance, yet there is ample axle clearance. All of which goes to show that considerable skill in designing may be expected at every tarn of the chassis.

The chassis weight with pneumatic tyres, wings and footsteps comes out at 271 cwt. With a van body and the vehicle ready for the road, the net unladen weight is 39 cwt. A flat-deck lorry body weighs 7 cwt. and one with hinged sides weighs about 11 cwt. Hence, the vehicle comes well within the weight limit for the class taxed at £26. As the weight that may be imposd on the chassis is 42 cwt., the pay load with a van or hingesided lorry is 30 cwt. and with a platform lorry is 35 cwt.

The height to the top of the frame (loaded) is 2 ft. 21 ins., which, with a wheel clearance provision of s32 101 ins, to the top of the wheel arch, gives a very low platform height. However, there is a clearance under the front axle of 111 ins, and wider the centre of the worm-wheel casing of 101 ins., so that no sacrifice is entailed in this respect. The standard wheelbase is 11 ft., and of the total overall chassis length of 16 ft. 61 ins, there is a space available for the body of 13 ft. 31 ins., of which 3 ft. 7 ins, is occupied by the cab, leaving a floor space of 9 ft. 81 ins. Of this, again, 5 ft. 81 ins, is in"front of the centre of the rear axle. These dimensions show that the body space is above normal for the size of the chassis and that the centre of gravity of the pay load is carried well forward.

The care taken over the dimensions and the disposition of the load is reflected in the steady running, comfortable riding and general stability of the machine under driving and braking torques.

The chassis was designed throughout in the firm's drawing office at TyseIey, so that the result materially differs from an assembly product, which is, perforce, based upon standard components that may not always marry together harmoniously. The utmost care is being devoted to the construction, whilst the testing of the complete vehicle is most thorough. Each component is fully tested on the bench, the engine-`being run under searching conditions with its own carbu retter, magneto, plugs and wiring. The gearbox and rear axle are both given running tests, whilst the completed vehicle is put to a series of road tests, the first under no load, the second under half load and the third under full load, over a hilly course of about 150 miles. The tester's report is a model of thoroughness, and as a result of this careful scrutiny, each vehicle reaches its purchaser in a state of running perfection.

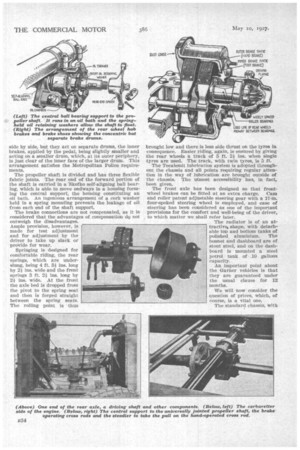

The four-cylindered engine has a separate head and a separate cylinder block. It has a total cylinder capacity of 2,613 cubic centimetres and develops 23.5 b.h.p. at 1.200 r.p.m., 28.6 b.h.p. at 1,500 r.p.m., and 35 b.h.p. at 2,000 Lein. Its torque curve is very satisfactory, as the torque in ft-lb. rises from 95 at 600 r.p.m. to 103 at 1,150 r.p.m., holding it to 1,200 r.p.m., the curve then falling easily to 96 ft.-/b. at 1,800 r.p.m. The crankshaft is a sturdy member, 2i ins, in diameter and supported in three journal bearings. The valves are placed at the side and are operated by easily adjustable tappets. The pistons, of cast-iron, are each equipped with three rings and a wide ring over the gudgeon-pin ends. Oil is circulated by a pump, which forces oil to pockets above the main bearings and to troughs into which the big-ends dip, and it can be dismantled as a unit without disturbing the base. The sump holds the useful quantity of two gallons of oil. The engine is equipped with a Zenith horizontal carburetter with an air strangler and filter and a Simms magneto with vernier coupling.

To the,bell housing over the fabric-faced cone clutch (with one central spring) the gearbox is bolted unitwise. Thesgearbox is a sturdy job with splined shafts 1.1 ins, in diameter and with large-diameter gearwheel,* in. wide. Four changes are afforded, operated by a lever centrally disposed and controlled by the usual type of gate. The gear ratios are: Top, direct; third, 1.58 to 1; second, 2.62 to 1; first, 5.28 to 1, the ratio of the reverse being 8.25 to 1. The final gear ratio between the worm and worm wheel is 6i to 1 (7 to 1 can be given for exceptional N.'ork). Nowadays, when clutches are constructed to call for so little attention, the unit construction of engine and gearbox has many advantages. The whole unit can be made a bench job; it can be removed complete to the bench for overhaul, and shaft alignment ensured before return to the chassis. If necessary to remove the gearbox only, this can he accomplished easily in 20 minutes, and a great advantage is found in having the gearbox right under the footboards instead of being below a trap door in the body. Such a trap door is utterly useless when there is a load on the vehicle. It is a sound principle that no working part should be Inaccessible when a vehicle is loaded.

The unit is suspended on three universal trunnion joints, first devised for the 40-50-cwt. chassis and proved sound in practice. The trunnion at the front end, however, is carried in a housing on the enginesupporting cross-member and the starting handle passes through it. The chassis, in our presence, successfully passed the test devised by the War Department, the frame being lifted by a front corner until both front wheels were clear of the ground, thus twisting the frame diagonally; the crankshaft of the engine and the gearing being then rotated by hand.

The rear axle is a sound job, special features being incorporated in the design of the hub mountings so that the bearings are widely spaced and the load line of the rear wheels falls midway between the bearings—a much more satisfactory arrangement than if the bearings are unequally stressed. The brakes are placed side by side, but they act on separate drums, the inner brakes, applied by the pedal, being slightly smaller and acting on a smaller drum, which, at its outer periphery, is just clear of the inner face of the larger drum. This arrangement satisfies the Metropolitan Police requirements.

The propeller shaft is divided and has three flexible fabric joints. The rear end of the forward portion of the shaft is carried in a "Skeflro self-aligning ball bearing, which is able to move endways in a housing forming the central support, the housing constituting an oil bath. An ingenious arrangement of a cork washer held in a spring mounting prevents the leakage of oil from each end of the shaft support.

The brake connections are not compensated, as it is considered that the advantages of compensation do not outweigh the disadvantages.

Ample provision, however, is made for test adjustment and for adjustment by the driver to take up slack or provide for wear.

Springing is designed for comfortable riding, the rear springs, which are underslung, being 4 ft. 34 ins, long by 2i ins, wide and the front springs 3 ft. 24 ins, long by 2i ins. wide. At the front the axle bed is dropped from the pivot to the spring seat and then is forged straight between the spring seats. The rolling point is thus brought low and there is less side thrust on the tyres In consequence. Easier riding, again, is ensured by giving the rear wheels a track of 5 ft. 24 ins, when single tyres are used. The track, with twin tyres, is 5 ft.

The Tecalemit lubrication system is adopted throughout the chassis and all points requiring regular attention in the way of lubrication are brought outside of the chassis. The utmost accessibility has, in fact, been given.

The front axle has been designed so that frontwheel brakes can be fitted at an extra charge. Cam and roller patent adjustable steering gear with a 17-in. four-spoked steering wheel is employed, and ease of steering has been considered as one of the important provisions for the comfort and well-being of the driver, to which matter we shall refer later.

The radiator is of an at tractiv%, shape, with detachable top and bottom tanks of polished aluminium. The bonnet and dashboard are of stout steel, and on the dashboard is mounted a steel petrol tank of 10 gallons capacity.

An important point about the Garner vehicles is that they are guaranteed under the usual clause for 12 months.

We will now consider the ouestion of prices, which, of course, is a vital one.

The standard chassis, with

Dunlop cushion-tyre equipment, is priced at 1328. Normal additions to such a chassis are a three-larap six-volt lighting set of a substantial kind, front wings and steps and mileage recorder. The extra inclusive price for this set is £19, bringing the price of the chassis up to £347.

The chassis, with Dunlop 32-in. by 6-in, single pneumatic tyre equipment, is priced at £338. With a spare wheel and pneumatic tyre, lighting set, mileage recorder, front wings and steps, the price is £372.

Provision is made for the buyer who wishes to keep his capital expenditure low, and particulars must he obtained from the detailed price 'list. We may, however, here refer to the bodies. The standard driver's cab, which includeS windscreen, dOor, cushion and backrest, turned out in works grey, is priced at £20. The standard cab with flat deck body, 9 ft. 10 ins, long by 6 ft. wide, including wings and steps, and in works grey, costs £50. The addition of hinged sides makes a difference of £5.

The standard van, which is of substantial construction, in which an ash framework and Plymax panels are employed, is priced at £75. This body has a loaded platform height of 2 ft. 61 ins., the wheel arches standing up about 7i ins, inside the body, but with the ample width of 4 ft. 2 ins. between them. The door openings are practically the full width of the van, and the interior capacity ig 387 cu. ft.

So many trades to-day accept the wheel arcfi that it is possible and practicable to build a chassis to a low frame level, as it is always easy to build up from such a level should a vehicle, normally, have to work from a loading platform at the old-fashioned horsevehicle height.

Consideration has been given to the driver in every way, the steering being light, the seating accommodation ample, and, with large windows, gloominess is entirely banished. Although there is a large amount of window area, there are no blind spots, and with an absence of draughts the driver is completely protected in all weathers.

consumption under full load has, so far, worked out as follows :—Petrol, one gallon to 171 miles over giveand-take roads; oil, one gallon over 1,665 miles.

The range of chassis will be completed by the employment of an engine giving more power than the ones so far specified, in a chassis the frame length of which would be 12 ft. This would accommodate a 20seater motor coach and would provide a fast, comfortable vehicle. A 20-seater bus can be produced with the chassis which we have described, having a 12-ft. wheelbase. These chassis will comply with all the Ministry of Transport regulations and will be equipped with undershield, etc.

From what we Faye said it will be seen that Messrs. Garner have aimed at producing a truly commercial vehicle without any ear part being employed therein, and it should be a vehicle that will run economically and have a long life, giving the advantages of large body space and a very creditable .road performance.