A PRIZE OP TEN SHILLINGS is awarded each week to

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

The sender of the best letter which we publish on this pgge all others paid for at the rate of a penny ct line, with an allowance for photographs. All notes are edited bqore being

publOwd. Mention pour employer's name, in clivifidenee, as evidence of good faith. Address 1)., M, and P.', The Commercial Motor." 7-n, Rosebery Avenue, London, E.C:

Lamps Alight.

Light your lamps at 9.10 in London, 10.12 in Edinburgh, 9.31 in Newcastle, 9.30 in Liverpool, 9.21 in Birmingham, 9.20 in Bristol, and 10.13 in Dublin.

Sparking-plug Protection.

The sender of the following conzwunieation has been awarded the ws. prize this week.

[1739] "Toby" (Cardiff) writes :—" On several occasions, when examining engines for ignition trouble, have discovered that the sparking plug points havo been in contact with the heads of the inlet vah'es. This does not argue necessarily bad design, but more generally it is owing to the valve having lifted further thah it should do normally under the control of the cash. This may happen occasionally at high speeds owing to the effects of inertia.

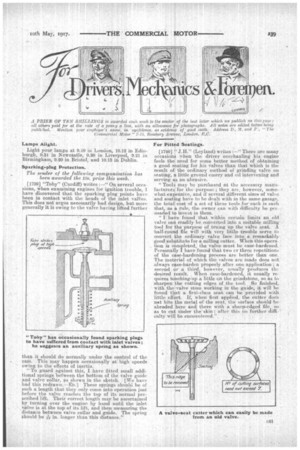

"To guard against this, I have fitted small additional springs -between the bottom of the valve guide and valve collar, as shown in the sketch. [We have had this redrawn.—En.1 These springs should be of such a length that they only come into operation just before the valve reaches the top of its normal prescribed lift. Their correct length may be ascertained by turning over the engine by band until the inlet valve is at the top of its lift, and then measuring the distance between valve collar and guide. The spring

should be in. longer than this distance." For Pitted Seat ings.

[1740] J.H." (Leyland) writes There are many

oecasionS when the driver overhauling his engine feels the need for some bettor method of obtaining a good seating for his valves than that which is the result of the ordinary method of grinding valve on seating, a little ground emery and oil intervening and serving As an abrasive.

" Tools may be purchased at the accessory manufacturers: for the purpose ; they are, however, somewhat expensive, and if several different sizes of valve and seating have to be dealt with in the same garage, the total cost of a set of these tools ,for each is such that, as a rule, the owner can with difficulty be persuaded to invest in them.

" I have found that within certain limits an old valve can readily be converted into a suitable milling tool for the purpose of truing up tho valve seat,. .A half-round file will with very little trouble s.,eive to convert he ordinary valve face into a remarkably good substitute for a milling cutter. When this operation is otimpleted, the valve must be cage-hardened... Personally I have found that two or three repetitions of the case-hardening process are better than one. The material of which the, valves are made does. not always case-harden properly after one application; a second or a third, however, usually Trodirees the desired result. When ease-hardened, it usually requires touching-up a little on the grindstone so as to sharpen the cutting edges of the tool. Sp 'finished, with the valve stem working in the guide, it will he found that a first-class seat can be provided with little effort. If, when first applied, the cutter does nod bite the metal of the seat, the surface should abraded here and there with a sharp-edged file, no as to eut tinder the skin ; after this no further difficulty will be encountered."