Possible Developments in

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

HYDRAULIC TRANSMISSION

Some Theoretical Considerations Simply Explained; How Multiwheel Drive Might be Obtained Hydraulically

ECENT developments in the use of hydraulic power trans mission are undoubtedly arousing considerable interest, and the present time would appear to be opportune to give a brief digest of my own experiments in this direction along lines which may be new to many readers.

In order to explain simply the means adopted to obtain an experimental, variably geared transmission, which would: if suitably developed, provide an alternative to the clutch and gearbox, the hest way appears to be to give a description of the original experimental apparatus tried out many years ago.

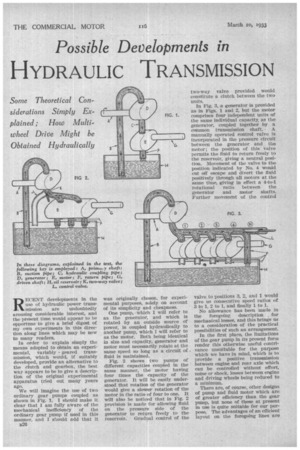

We will imagine the use of two ordinary gear pumps coupled as shown in Fig. 1. I should make it clear that I am fully aware -of the mechanical inefficieney of the ordinary gear pump if used in this manner, and I should add that it B26 was originally chosen, for experimental purposes, solely on account of its simplicity and cheapness.

One pump, which I will refer to as the generator, and which is rotated by an outside source of power, is coupled hydraulically to another pump, which I will refer to as the motor. Both being identical in size and capacity, generator and motor must necessarily rotate at the same speed so long as a circuit of fluid is maintained.

Pig. 2 shows two pumps of different capacities coupled in the same manner, the motor having four times the capacity of the generator. It will be easily understood that rotation of the generator would give a slower rotation of the motor in the ratio of four to one. It will also be noticed that in Fig. 2 provision is made for allowing fluid on the pressure side of the generator to return freely to the reservoir. Gradual control of the two-way valve provided would constitute a clutch between the two units.

In Fig. 3, a generator is provided as in Figs. 1 and 2, but the motor comprises four independent units of the same individual capacity, as the generator, coupled together by a common transmission shaft. A manually operated control valve is incorporated in the pressure circuit between the generator and the motor ; the position of this valve permits the fluid to return freely to the reservoir, giving a neutral position. Movement of the valve to the position indicated by No. 4 would cut off escape and divert the fluid positively through all motors at the same time, giving in effect a 4-to-1 rotational ratio between the generator and motor shafts. Further movement of the control valve to positions 3, 2, and 1 would give us consecutive speed ratios of 3 to 1, 2 to 1, and finally 1 to 1.

No allowance has been made in the foregoing description for mechanical losses, and this brings us to a consideration of the practical possibilities of such an arrangement.

In the first place, the limitations of the gear pump in its present form render this otherwise useful contri , vance unsuitable for the purpose which we have in mind, which is to Provide a positive transmission between engine and rear axle which can be controlled without effort, noise or shock, losses between engine and driving wheels being reduced to a minimum.

There are, of course, other designs of pump and fluid motor which are of greater efficiency than the gear pump, but none of these at present in use is quite suitable for our purpose. The advantages of an efficient layout on the foregoing lines are

obvious and, accordingly, there would appear to be an opportunity for research in this direction, given efficient units of suitable size with a correctly designed port, conduit and control-valve system. Granted that the many difficulties can be overcome, a further field of experiment would be opened up by the utilization of such a drive in multi-wheeled vehicles.

To take the rigid six-wheeler as an example, many examples of this type of vehicle have only one pair of driven wheels. Taking the drive to all four rear wheels involves costly additions and mechanical difficulties.

There are few engineers who would not agree that the ideal would be realized by a practical design permitting independent-vertical or radial movement (in relation to the chassis frame), of each driving wheel, combined with a drive and separate compensated braking to each of the four rear wheels. With present design the springing and transmission of many vehicles is subjected to great stresses when working on uneven

ground. There also are instances of bad braking under these conditions.

It may become possible to utilize hydraulic transmission, and eliminate some of the troubles which are common to this type of vehicle. It will. be realized that in the first place, remote positions of driving and driven units are possible with an arrangement such as I have described, and suitably designed flexible conduits would permit sufficient relative movement between. generator and motor to allow the" motors to be mounted on each driving axle. Again, the conduits between the generator and the separated motor units, supposing one to be mounted to drive each of the four rear wheels of a six-wheeler, would obviate differential gearing, the conduits themselves, by maintaining balanced pressure, giving differential drive.

Further, braking could possibly be arranged by allowing the pressure lines to become suction lines, the 'braking being then effected by restricting the return Mow of fluid on the 'release side of the motor units. A certain amount of the expense which would be involved by the use of such a layout could be off-set by reverting to the straight chassis frame, ousted by the arched • chassis only as a result of the demand for a lower loading line and the impossibility of providing this improvement , without arching the frame.

Taking all things into consideration, it would appear that the whole question of positive. hydraulic transmission is worthy of serious attention on the part of our designers and manufacturers at a time when the multi-wheeled, multiwheel-driven vehicle is in great

demand. O.E.F.