THE DESIGN OF THE FODEN SIX-WHEELER.

Page 77

Page 78

If you've noticed an error in this article please click here to report it so we can fix it.

The Simple Form of Transmission of the New 10-ton to 12-ton Rigid-frame

Steam Wagon.

ALTFIOUGH the Foden rigid-frarne six-wheeler has now been in service for some little time, it has not been previously fully described or illustrated, nor has its sale been pushed amongst users, because it is part of the conservative policy of the directors of rodeas, Ltd., to give any new product a gruelhug test in ordinary service at the hands of a few selected users and to refrain from making any claims for its products until the experience gained has proved that the vehicles may be offered with perfect confidence. Thus, the sixwheeler has had many months of severe testing in actual service, and its performance has been thoroughly studiod under various conditions, and now the maker is prepared to offer it as a firstclass engineerjng job.

rodens, Ltd., was amongst tie earliest makers to adopt the principle of six wheels with a rigid frame, aid it is interesting to note that a drawing is in existence (of which we have been enabled to make a copy) showiog the layout of a six-wheeler designed in the year 1903-25 years ago—in which the two rear axles are placed as close together as possible and all four bogie wheels are used for propulsion. We are unable to say whether such a vehielo was built, but have put the question to the maker , neither are we able 'o ascertain the proposed method of rearspring suspension.

The new Foden six-wheeler is claimed. to have a capacity of from 10 to 12 tons. The engine and boiler used ere the same as those employed for rio well-known •8-tonner, the crankshaft and eccentrics being mounted on roller bearings, thus making for efficient and smooth running of the engine. The boiler pressure has been raised to 230 lb. per sq. in., and every boiler is tested to a pressure of 380 lb. per sq. in.

The frame of the vehicle is of rolledsteel channels, 9 ins, deep and 3 'as. in cross-section, well braced with steel cross-members and gussets and supported underneath on each side by a strong strut suitably stayed.

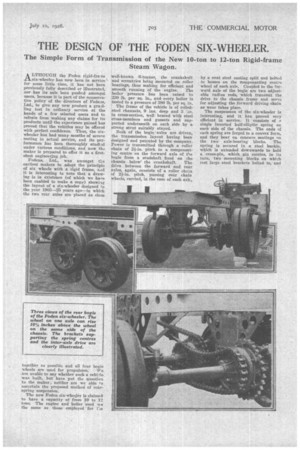

Both of the bogie axles are driven, the transmission layout having been designed and patented by the company. Power is transmitted through a roller chain of 2i-in. pitch to a compensating centre on the forward axle of the bogie from a studshaft fixed on the chassis below the crankshaft. The drive between the forward and rear axles, again, consists of a roller chain of 241-in. pitch, passing over chain wheels, carried, in the case of each axk,

by a neat steel casting split and bolted to bosses on the compensating centre wheel of each axle. Coupled to the forward axle of the bogie are two adjustable radius rods, which transmit the drive to the chassis frame and serve for adjusting the forward driving chain as wear takes place.

The suspension of the six-wheeler is interesting, and it has proved very efficient in service. It consists of s single inverted half-elliptic spring on each side of the chassis. The ends of each spring are forged to a convex form, and they bear on concave Beatings on the two axle-bearing blocks. The spring is secured in a steel buckle, which is extended downwards to hold a cross-pin, which pin carries, in its turn, two mounting blocks on which rest large steel brackets bolted to, and suspended from, the side-member of the' frame, the arrangement being the same, of course, on both sides of the chassis.

Both axles are positioned in relation to the spring-mounting blocks and consequently to each other by means ot short connecting rods coupled to he bearing blocks at one end and with a ball-pin joint to the mounting blocks at the other end; the latter are 'made slidable, so that when chain adjustment takes pace both axles move in perfect alignmeet and unison. This method of springing is claimed to give exceptional freedom to the axles when travelling over uneven ground, as each wheel can rise or fall 101 ins, above or below the other without transmitting any stresses to the chassis frame or to any other component. Similarly, the axles can be set crosswise and out of horizontal alignment by the wheels being on humps and in pot-holes et opposite corners, without transmitting any undue strain to the chassis.

This freedom is, of course, essentiel in rigid six-wheeler design, because it is the attribute that allows tbat type of vehicle to suit itself to the unevenness—however excessive—of any road surface and permits the vehicle to pass over rough ground. It will thus be seen that the Toden six-wheeler is driven through all four wheels of the bogie, and not (as was presumed in an earlier issue of The Commercial Motor) on only the front axle of the bogie.

With' the coming of bigger loads and the call for much higher speeds, the need for better brakes lias become more insistent. The Paden six-wheeler is well provided in the matter of brake power, because it has powerful independent cam brakes to each of the bogie axles operated by a brake pedal in the driver's cab. An automatic catch is brought into actron in order to take the pressure from the driver's foot whilst the brake is being, held on; this catch can be instantly released at will.

'The steering gear is designed on the Ackerman principle, with .centratly pivoted Stub axles, and is,claimed to be Particularly easy. The cab is roomy and free from awkward projections, has upholstered seats, and a three-pas:1 adjustable windscreen, whilst for night travelling the vehicle is equipped with electric light, the dynamo being driven from the flywheel and being easily accessible for such small attentions as it requires.

The coal bunkers are disposed under the two seats, each bunker having sliding doors, and the firing is made very simple because the bottom of the irehole door is placed on a level with Se footplate.

The lubrication of this chassis throughout is effected through greasegun nipples wherever possible.

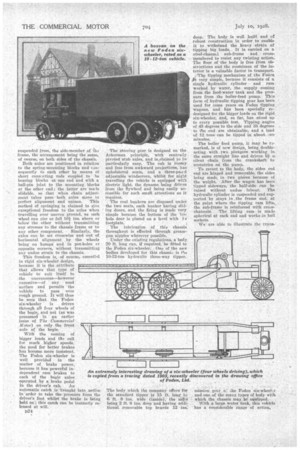

Under the existing regulations, a body 20 ft. long can, if required, be fitted to the Foden six-wheeler. One of the new bodies developed for this chassie is the 10-12-ton hydraulic three-way tipper.

The body which the company offers for the standard tipper is 15 ft. long by 6 ft. 9 ins. wide (inside); the sides being 2 ft. 6 ins, deep and having additional, removable top beards 12 ins.'

deep. The body is well built and of robust construction in order to enable it to withstand the heavy strain of tipping big loads. It is carried on a eteel-channel sub-frame and crossmembered to resist any twisting action. The floor of the body is free from obstructions and the roominess of the interior is a valuable factor in transport.

The tipping mechanism of the Fdden is very simple, because it consists of a single hydraulic cylinder and ram worked by water, the supply coming from the feed-water tank and the pressure from the boiler-feed pump. This form of hydraulic tipping gear has been used for some years on Foden tipping wagons, and has been • specially redesigned for the bigger loads on the rigid,. six-wheeler, and, so far, has stood up to every possible test. Tipping angles of 45 degrees to the side and 38 degrees to tlie end are obtainable, and a load of 12 tons can be tipped in about eso minutes.

• The boiler feed pump, it may be remarked, is of new design, being doubleacting with two. plungers working in the same straight line and driven b3r ne silent chain from the crankshaft to 'eccentrics on the pump.

To revert to the body, the sides trill end are hinged and removable, the sides being made in two pieces: because of the weight. After the wagon has been tipped sideways, the half-side can be raised without undue . labour. The hydraulic cylinder is suspended and supported by stays in the frame and, at the point where the tipping rain the sub-frame is reinforced with crosschannels. The lifting ram is made spherical at each end and works in hall soekets.

We are able to illustrate the trans mission gear o: Foden six-wheeler and one of the many types of body with which the chassis mayebe` equipped. , 'With a large water tank, this vehicle has a considerable range of action.