A Power-operated Gear Shift

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

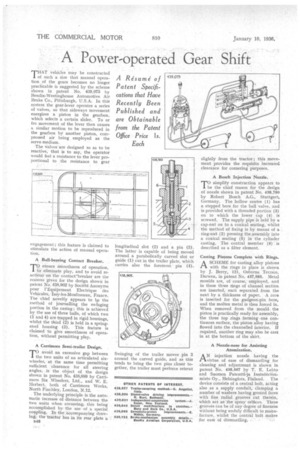

THAT vehicles may be constructed 1 of such a size that manual operation of the gears becomes no longer practicable is suggested by the scheme shown in patent No. 4:39,075 by Bendix-Westinghouse Automotive Air Brake Co., Pittsburgh, U.S.A. In this system the gear-lever operates a series of valves, so that sideways movement energizes a piston in the gearbox, which selects a certain slider. To or fro movement of the lever then causes a similar motion to be reproduced in the gearbox by another piston, compressed air being employed as the servo medium.

The valves are designed so as to be reactive, that is to say, the operator would feel a resistance to the lever proportional to the resistance to gear engagement ; this feature is claimed to stimulate the action of manual operation.

A Ball-bearing Contact Breaker.

T.9ensure smoothness of operation, 'to eliminate play, and to avoid reactidith on the contactThreaker are the reasons 'given for the design shown in patent No; 438,902 by Societe Anonyme pour l'Equipement Electrique des VehiculeS, .Issy-les-Moulineaux, France, The chief novelty appears to be the method of journalling the swinging portion in the casing ; this is achieved by the use of three balls, of which two (1' and 4) are trapped in rigid housings, whilst the third (2) is held in a springsteel housing (3). This feature is claimed to give smoothness of operation, without permitting play.

• A Carrimore Semi-trailer Design.

TO avoid an excessive gap between 1 the two units of an articulated sixwheeler, at the same time permitting sufficient clearance for all steering angles, is the object of the design shown in patent No. 438,889 by Carrimore Six .Wheelers, Ltd., and W. E. Herbert, both of Carrimore Works, North Finchley, London, N.12.

The underlying principle is the automatic increase of distance between the two units when cornering, this being accomplished by the use of a special coupling. In the accompanying drawing, the tractor has in its rear plate a B48

longitudinal slot (2) and a pin (3). The latter is capable of being moved around a parabolically curved slot or guide (1) cut in the trailer plate, which carries also the foremost pin (4)•

A Bosch Injection Nozzle.

TO simplify construction appears to be the chief reason for the design of nozzle shown in patent No. 438,780 by Robert Bosch A.G., Stuttgart, Germany. The hollow centre (I) has a stepped bore for the ball valve, and is provided with a threaded portion (3) on to which the lower cap (4) is screwed. The supply pipe is held by a cap-nut on to a conical seating, whilst the method of fixing is by means of a ring-nut (2) pressing the assembly into a conical seating (5) in the cylinder casting. The central member (6) is described as a filter element.

Casting Pistons Complete with Rings.

ASCHEME for casting alloy pistons with the rings in place is shown by J. Berry, 121, Osborne Terrace, Danven, in patent No, 437,985. Metal moulds are, of course, employed, and in these three rings of channel. section are inserted, each separated from the next by a thickness of paper. A core is inserted for the gudgeon-pin. bore, and the molten metal is then forced in. When removed from the mouldthe piston is practically ready for assembly, the three top rings formingone continuous surface, the piston alloy having flowed into the channelled interior. If required, another ring may also be cast in at the bottom of the skirt.

A Nozzle-nose for Assisting Atomization.

AN injection nozzle having the virtue of ease of dismantling for cleaning and adjustment is shown in patent No. 438,567 by T. E. Lehto and Suomen Patentti-ja Insin64ritoimisto Oy., Helsingfors, Finland. The device consists of a central bolt, acting also as a supply conduit, clamping a number of washers having ground faces with fine radial grooves cut therein, which act as the spray orifices. These grooves can be of any degree of fineness without being unduly difficult to manufacture, whilst the central bolt makes for ease of dismantling.