A New Make of Oil Engine

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

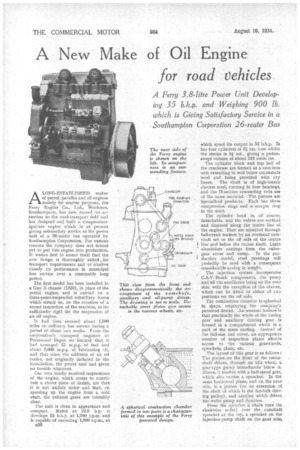

for road vehicles A Ferry 3.8-litre Power Unit Developing 35 b.h.p. and Weighing 900 lb. which is Giving Satisfactory Service in a Southampton Corporation 26-seater Bus ALONG-ESTABLISHED maker of petrol, paraffin and oil engines mainly for marine purposes, the Ferry Engine Co., Ltd., Woolston, Southampton, has now turned its atrtention to the road-transport field and has designed and built a compressionignition engine which is at present giving satisfactory service as the power unit of a 28-seater bus operated by Southampton Corporation. For various reasons the company does not intend yet to put this engine into production. It wishes first to assure itself that the new design is thoroughly suited ; for transport requirements and to observe closely its performance in municipal bus service over a reasonably long period.

The first model has been installed in a Guy B chassis (1920), in place of the petrol engine, and is carried on a three-point-suspended subsidiary frame which struck us, on the occasion of a recent inspection of the machine, as insufficiently rigid for the suspension of an oil engine.

, It had then covered about 1,500 miles on ordinary bus service during a period of about two weeks. From the corporation's transport engineer at Portswood Depot we learned that it had averaged 15 m.p.g. of fuel and about 2,000 m.p.g. of lubricating oil, and that since the addition of an oil cooler, not originally included in the installation, the power unit had given no trouble whatever.

Our own briefly received impressions of the engine, which seems to constitute a clever piece of design, are that it is not unduly noisy and that, on speeding up the engine from a cold start, the exhaust gases are tolerably clear. .

The unit is clean in appearance and compact. Rated at 22.5 h.p. it develops 35 b.h.p. at 1,200 r.p.m. and is capable of exceeding 1,800 r.p.m., at

B30

which speed its output is 50 b.h.p. It has four cylinders of 31 ins, bore whilst the stroke is Si ins., giving a piston. swept volume of about 232 cubic ins.

The cylinder block and top half of the crankcase are formed as a cast-iron unit extending to well below crankshaft level and being provided with dry liners. The shaft is of high-tensile chrome steel, running in four bearings, and the H-section connecting rods are of the same material. The pistons are Specialloid products. Each has three compression rings and a scraper ring in the skirt.

The cylinder head is, of course,

detachable, and the valves are vertical and disposed along the centre line of

the engine. They are operated through bell-crank rockers by an overhead camshaft set to the off side of the centre line and below the rocker shaft. Light aluminium castings form the valvegear cover and sump. In the pro duction model, steel pressings will probably be used with a consequent considerable saving in weight.

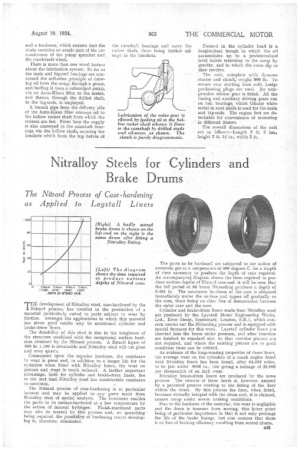

The injection system incorporates C.A.V.-Bosch components, the pump

and all the auxiliaries being on the near side, with the exception of the starter, -which can be fitted in either of two positions on the off side.

The combustion chamber is spherical in shape, employing the company's

patented design. An unusual feature -is

that practically the whole of the timing gear and auxiliary driving gear is

housed in a compartment which is a

part of the main casting. Instead of the full-size end cover, an appropriate number of inspection plates affords access to the various gearwheels, sprockets, chain, etc.

The layout of this gear is as follows : The pinion_on the front of the crank

shaft drives, through an idle wheel, a gear-type pump immediately below it. Above, it meshes with a half-speed gear,

which also carries a sprocket. In the same horizontal plane, and on the near side, is a pinion (on an extension of the shaft of which is the fan-belt driving pulley), and another which drives the water pump and dynamo.

From the sprocket a chain runs (in clockwise order) over the camshaft sprocket at the top, a sprocket on the injection-pump shaft on the aear side, and a tensioner, which ensures that the chain encircles an ample part of the circumference of the pump sprocket and the crankshaft wheel.

There is more than one novel feature about the lubrication system. So far as the main and big-end bearings are concerned the orthodox principle of drawing oil from the sump, through a gauze, and feeding it from a submerged pump, via an Auto-Klean filter to the mains, and thence, through the drilled shaft, to the big-ends, is employed.

A branch pipe from the delivery side of the Auto-Klean filter conveys oil to the hollow rocker shaft from which the rockers are fed. From here the supply is also conveyed to the camshaft bearings, via the hollow studs, securing the brackets which form the top halves of

the camshaft bearings and carry the rocker shaft, there being further oilways in the brackets.

Formed in the cylinder head la a longitudinal trough in which the oil accumulates up to a predetermined level before returning to the sump by gravity, and in which the cams dip as they revolve.

The unit, •complete with dynamo starter and clutch, 'weighs 900 lb. To ensure easy starting from cold, Lodge pre-heating plugs are used. No compression release gear is fitted. All the timing and auxiliary driving gears run on ball bearings, whilst Glacier white metal in steel shells is used for the main and big-ends. The engine feet are detachable for convenience of mounting in different frames.

The overall dimensions of the unit are as follow :—Length 3 ft. 2 ins, height 3 ft. 1.1 in., width 2 ft.