MERCEDES 32-ton Artic Excels

Page 60

Page 61

Page 62

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon,

A. M .I.R.T.E.

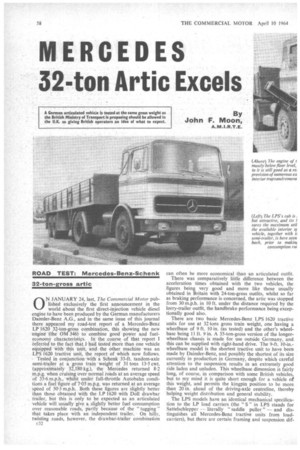

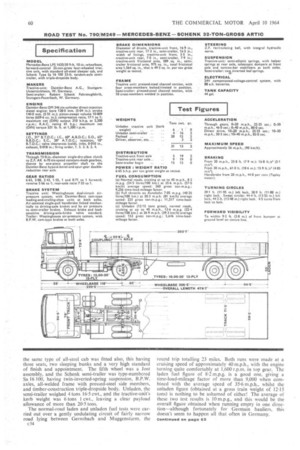

32-ton-gross artic 0 N JANUARY 24, last, The Commercial Motor published exclusively the first announcement in the world about the first direct-injection vehicle diesel engine to have been produced by the German manufacturers Daimler-Benz A.G., and in the same issue of this journal there appeared my road-test report of a Mercedes-Benz LP 1620 32-ton-gross combination, this showing the new engine '(the OM 346) to ' combine good .power and fueleconomy characteristics. In the. .co.urse of that report I referred. to the fact thia had tested Moie than One vehicle equipped . with this unit, and the other machine was an LPS 1620 tractive Unit, the report of which now follows. Tested in conjunction with a Schenk • 33-ft. tandem-axle semi-trailer at a ,groks train weight of 31 tons 13.5 cwt. (approximately 32,180 kg.), the Mercedes returned 8.2 'm.p.g. when cruising over normal roads at an average speed of 35.6 m.p.h., whilst under full-throttle Autobahn conditions a fad figure of '7.05 m.P.g. was returned at an average speed of 50.3 m.p.h.. Both these figures are slightly better than those olotained with the LP 1620 with Doll drawbar trailer, but this is only to be expected as an. articulated vehicle will usually give .a ,slightly better fuel consumption over reasonable roads, partly because of the " tugging " that takes place -With an independent trailer. On hilly, twisting .roads, however, the drawbar-trailer combination

c3? can often be more economical than an articulated outfit.

There was comparatively little difference between the acceleration times obtained with the two vehicles, the figures being very good and more like those usually obtained in Britain with 24-ton-gross outfits, whilst so far as braking performance is concerned, the ache was stopped from 30 m.p.h. in 10 ft. under the distance required by the lorry-trailer outfit, the handbrake performance being exceptionally good also.

There are two basic Mercedes-Benz LPS 1620 tractive units for use at 32 tons gross train weight, one having a wheelbase of 9 ft. 10 in. (as tested) and the other's wheelbase being 11 ft. 9 in. A 35-ton-gross version of the longerwheelbase chassis is made for use outside Germany, and this can be supplied with right-hand drive. The 9-ft. 10-in.wheelbase model is the shortest tractive unit to have been made by Daimler-Benz, and possibly the shortest of its size currently in production in Germany, despite which careful attention to the suspension results in an extremely good ride laden and unladen. This wheelbase dimension is fairly long, of course, in comparison with some British vehicles, but to my mind it is quite short enough for a vehicle of this weight, and permits the kingpin position to be more than 20 in. ahead of the driving-axle centreline, thereby helping weight distribution and general stability.

The LPS models have an identical mechanical specification to the LP load carriers (the " S " in LPS stands for Sattelschlepper -literally "saddle puller" — and distinguishes all Mercedes-Benz tractive units from loadcarriers), but there are certain framing and suspension dif ferences. The side members, for instance, have the same basic section of those of the LP, but inverted-L plates are riveted to the outsides of the main members, extending from a point just ahead of the frontaxle centreline to the extreme rear of the frame, with their upper flanges 4-33 in. above the main-member top flanges. This arrangement simplifies frame production in that it allows the same basic press tools to be used for both types of frame, gives the requisite mid-wheelbase frame strength for articulated working and, furthermore, allows the fifthwheel coupling to be bolted directly to the frame.

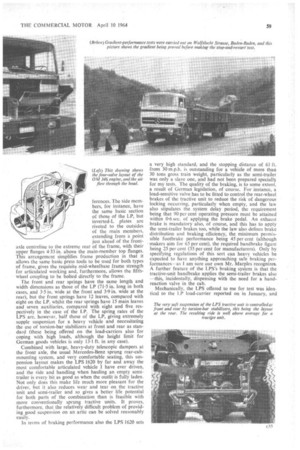

The front and rear springs have the same length and width dimensions as those of the LP (71-5 in. long in both cases, and 3.5 in. wide at the front and 3.9 in. wide at the rear), but the front springs have 12 leaves, compared with eight on the LP, whilst the rear springs have 15 main leaves and seven auxiliaries, compared with eight and five respectively in the case of the LP. The spring rates of the LPS are, however, half those of the LP, giving extremely supple suspension for a heavy vehicle and necessitating the use of torsion-bar stabilizers at front and rear as standard (these being offered on the load-carriers also for coping with high loads, although the height limit for German goods vehicles is only 13.1 ft. in any case).

Combined with large, heavy-duty telescopic dampers at the front axle, the usual Mercedes-Benz sprung rear-cabmounting system, and very comfortable seating, this suspension layout makes the LPS 1620 by far and away the most comfortable articulated vehicle I have ever driven, and the ride and handling when hauling an empty semitrailer is every bit as good as when the outfit is fully laden. Not only does this make life much more pleasant for the driver, but it also reduces wear and tear on the tractive unit and semi-trailer and so gives a better life potential for both parts of the combination than is feasible with more conventionally sprung tractive units. It proves, furthermore. that the relatively difficult problem of providing good suspension on an artic can be solved reasonably easily.

In terms of braking performance also the LPS 1620 sets a very high standard, and the stopping distance of 61 ft. from 30 m.p.h. is outstanding for a vehicle of more than 30 tons gross train weight, particularly as the semi-trailer was only a slave one, and had not been prepared specially for my tests. The quality of the braking, is to some extent, a result of German legislation, of course. For instance, a load-sensitive valve has to be fitted to control the rear-wheel brakes of the tractive unit to reduce the risk of dangerous locking occurring, particularly, when empty, and the law also stipulates the system delay period, the requirement being that 90 per cent operating pressure must be attained within 0.6 sec. of applying the brake pedal. An exhaust brake is mandatory also, of course, and this has to apply the semi-trailer brakes too, while the law also defines brake distribution arid braking efficiency, the minimum permissible footbrake performance being 45 per cent (although makers aim for 65 per cent), the required handbrake figure being 25 per cent (35 per cent for manufacturers). Only by specifying regulations of this sort can heavy vehicles be expected to have anything approaching safe braking performances—as I am sure our own Mr. -Marples recognizes. A further feature of the LPS's braking system is that the tractive-unit handbrake applies the semi-trailer brakes also —this, incidentally, dispensing with the need for a handreaction valve in the cab.

Mechanically, the LPS offered to me for test was identical to the LP load-carrier reported on in January, and the same type of all-steel cab was fitted also, this having three seats, two sleeping bunks and a very high standard of finish and appointment. The fifth wheel was a Jost assembly, and the Schenk semi-trailer was type-numbered • Sa 16 100, having twin-inverted-spring suspension, B.P.W. axles, all-welded frame with pressed-steel side members, and timber-construction triple-dropside body. Unladen, the semi-trailer weighed 4 tons 16-5 cwt., and the tractive-unit's kerb weight was 6 tons 1 cwt., leaving a clear payload allowance of more than 20.5 tons.

The normal-road laden and unladen fuel tests were carried out over a gently undulating circuit of fairly narrow road lying between Gernsbach and Muggensturm, the e34 round trip totalling 23 miles. Both runs were made at a cruising speed of approximately 40 m.p.h., with the engine turning quite comfortably at 1,600 r.p.m. in top gear. The laden fuel figure of 8-2 m.p.g. is a good one, giving a time-load-mileage factor of more than 9,000 when combined with the average speed of 35.6 m.p.h., whilst the unladen figure (obtained at a gross train weight of 12-15 tons) is nothing to be ashamed of either! The average of these two test results is 10 m.p.g., and this would be the overall figure obtained when running empty in one direction—although fortunately for Germain hauliers, this doesn't seem to happen all that often in Germany.

A 16.2-mile circuit of Autobahn was used for the highspeed fuel test, which was made with full throttle in use continuously. The average speed of 50.3 m.p.h. resulting from this test is very little below the outfit's maximum speed—indicating the ability • to Maintain a high cruising speed under normal Autobahn conditions—whilst the consumption rate of just over 7 m.p.g. is highly satisfactory also. While travelling at more than 50 m.p.h. the LPS was remarkably quiet inside the cab, and the outfit-was smooth and stable at all times, thereby leaving the driver free to concentrate on road conditions without having to worry about his own vehicle. I was to drive the outfit later over the same stretch of Autobahn, and was particularly impressed with the steadiness of the steering, the latest Z.F. recirculatory-ball hydraulically-assisted gear giving positive control, with no trace of the wander sometimes experienced with power-assisted systems when trying to maintain a straight-ahead course at speed.

The acceleration figures obtained with the attic are fully detailed in the accompanying data panel, and virtually speak for themselves, showing the LPS to be no sluggard when it comes to getting away from a standstill. Although not a synchromesh gearbox, the remote-control linkage is efficient enough to give light changing with the minimum of delay, and the lever is well positioned relative to the driving seat. Direct-drive performance proved to be quite satisfactory in view of the outfit's weight, and the engine and transmission were perfectly smooth when making these fifth-gear tests.

As already commented on, very good braking figures were obtained from the outfit. The first test from 30 m.p.h. revealed harshness of the semi-trailer brakes, resulting in a certain amount of bucking, which caused the test weights to move forward slightly. After this stop, however, the other tests were quite smooth, and consistent Tapley-meter readings of more than 80 per cent were obtained. On one occasion the left rear wheels of the semi-trailer locked for 6 ft., whilst on another stop the left driving wheels locked for a short distance, making the rear of the tractive unit slide to the left a bit. The handbrake performance from 20 m.p.h. could hardly help being good in view of the• interconnection with the semi-trailer brakes, and 44 per cent was obtained on the Tapley meter during two stops from this speed.

As with the LP combination, the hilt tests were conducted on Wolfslucht Strasse, Baden-Baden, the average gradient of this climb being 1 in II, and the length 1.25 hmiles. A non-stop climb made in an ambient temperature of 12°C (54°F) was completed in a total time of 10 min. 20 sec. (40 sec. faster than with the LP and trailer), and this caused the engine-coolant temperature to rise• from 78°C (I72°F) to 80°C (176°F), showing entirely adequate engine cooling. Bottom gear was used for 6 min. 40 sec. during this ascent, with the engine running on the governor almost all thc time, and there was no exhaust smoking.

The exhaust brake was used during the descent, which lasted for 9 min. 55 sec., of which time 7 min. 22 sec. was spent in bottom gear. The footbrake was not employed at all, and the exhaust brake was being applied for 2 to 3 sec. at a time at 3to 4-sec. intervals, while in bottom gear, This is standard practice for German drivers when descending hills of this severity, and is a simple one to adopt, the main secret being to keep an eye on the rev, counter to avoid overspeeding the engine.

The Wolfslucht has a maximum gradient of 1 in 6.7 (15 per cent), and on this slope the outfit's handbrake held it quite easily when facing in either direction. I failed to make restarts in bottom and reverse because of clutch slip, but the Mercedes driver managed allaight, even though the reverse restart was accompanied by profuse exhaust smoking. This was, however, the only time I saw this engine smoke.

As will perhaps have been gathered already, I was more than pleased with the overall performance of this MercedesBenz articulated outfit from all aspects, and apart from a possibility that the clutch might not really be big enough (as evidenced by the ease with which I brought on clutch slip while making the gradient-restart tests), it is difficult to fault the design in any respect. Admittedly, greater engine power would always be an advantage--as with all heavy vehicles--but The LPS 1620 has a good power-toweight ratio as it is, and the spread of gear ratios suits the engine's characteristics very well indeed, so there can be few artics of any weight with a better overall performance.

Compared with the LP-type load-carrier, my most lasting impression of the LPS tractive unit concerns the suspension. Even the pitching normally unavoidable with the best of tractive units so far appears to be absent, whilst the way the Daimler-Benz engineers have managed to get the unladen ride as good as the laden ride rouses my utmost admiration. The driving position is good, the high floor line gives a wide field of forward and sideways vision, and the layout of the controls and instruments could hardly be bettered, In respect of engine noise, the underfloor location of the power unit makes this as unobtrusive as can be expected—particularly in view of the 210 healthy horses providing the power.

It was interesting, incidentally, to watch two quite strong men struggle with the semi-trailer's landing gear while disconnecting it prior to the unladen work (for which a different semi-trailer was used). Obviously, when Britain joins the ranks of the countries which permit their commercials to operate at 32 tons gross, there will be a good market for a reasonably-priced hydraulic landing gear, for lifting the nose of a semi-trailer carrying a 20-ton load is certainly not child's play.

So far as life of the new design is concerned, the main chassis components are based on those of earlier MercedesBenz vehicles of this weight, so are well proved already. The cab should give no trouble, being very well built and designed, whilst the engine should be able to live with the rest of the vehicle, some of the original versions of the OM 346 unit having been running for well over two years, and one in particular, which was stripped down after 122,000 miles, showing a maximum bore wear of only 0.00175 in. whilst the main and big-end bearings were within 0.0604 in. of their nominal upper limits.

The list price in Germany of the LPS 1620/30 chassis tested is the equivalent of £4,250, the cab price being an extra £520. The 11-ft. 9-in.-wheelbase model costs some £22 more than the short-wheelbase version. Schenk list the basic price of their Sa 16 100 semi-trailer as about £2,250, including bodywork, so the complete outfit comes out at a little more than £7,000. Quite a lot of money— but WS possible to pay much more for far less impressive vehicles. . . .