CASTROL GRID HELPS OPERATORS...

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

A PLANNED lubrication system can help the operator combat the ever present problem of rising costs. Remember: the important word is planned.

The whole concept of planned lubrication and planned maintenance in general sterns from the introduction of the Goods Vehicles (Plating and Testing) Regulations 1968. At that time it was thought that the industry needed a well laid out chart of items requiring attention at various titoe scale points.

The idea was that if a mechanic had a definite pattern to woik to, then less items would be missed. It was realised at the time that any system would have to be flexible to meet individual requirements and to allow operators, in certain cases, to superimpose it over an existing system.

Castrol has developed a planned fleet maintenance scheme aimed at making the operator's life a little easier.

One of the ways it can help is by reducing the number of lubricants carried in stock by the operator. According to Castrol, it is very rare indeed to find a ease where some degree of ration alisation is not possible. Cutting down on the number of different oils, greases, etc, allows the fleet engineer to take advantage of any cost savings available through bulk buying.

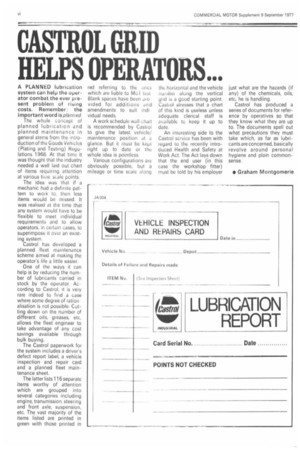

The Castrol paperwork for the system includes a driver's defect report label, a vehicle inspection and repair card and a planned fleet maintenance sheet.

The latter lists 11 6 separate items worthy of attention which are grouped into several categories including engine, transmission, steering and front axle, suspension, etc. The vast majority of the items listed are printed in green with those printed in

red referring to the ,,ncs which are liable to MoI Lest Blank spaces have been pie vided for additions and amendments to suit indi vidual needs.

A work schedule wall ahart is recommended by Castiol to give the latest vehicle/ maintenance position at a glance. But it must be kept right up to date or the whole idea is pointless.

Various configurations are obviously possible, but a mileage or time scale along the horizontal and the vehicle nueibei along the vertical grid is a good starting point. Castiol stresses that a chart of this kind is useless unless adequate clerical staff is available to keep it up to date.

An interesting side to the Castrol service has been with iegard to the recently introduced Health and Safety at Work Act. The Act lays down that the end user (in this case the workshop fitter) must be told by his employer just what are the hazards (if any) of the chemicals, oils, etc, he is handling.

Castrol has produced a series of documents for reference by operatives so that they know what they are up to. The documents spell out what precautions they must take which, as far as lubricants are concerned, basically revolve around personal hygiene and plain commonsense.

• Graham Montgomerie