A SINGLE-MOTOR TROLLEY-BUS

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

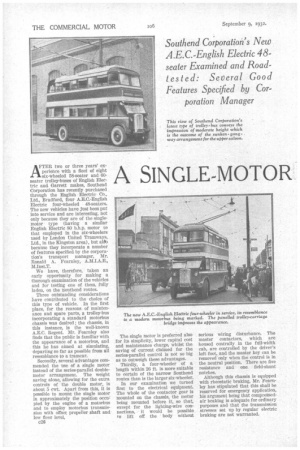

in service

AFTER two or three years' experience with a fleet of eight six-wheeled 58-seater and 60seater trolley-buses a English Electric and. Garrett makes, Southend Corporation has recently purchased through the English Electric. Co-, Ltd., Bradford, four A.E.C.-English Electric four-wheeled 48-seaters. The new vehicles have just been put into service and are interesting, not only because they are of the singlemotor type (having a similar English Electric 80 b.h.p. motor to that employed in the six-wheelers used by London United Tramways, Ltd., in the Kingston area), but alhu because they incorporate a number of features specified by the corporation's transport manager, Mr. Ronald A. Fearnley, A.M.I.A.E., KInst.T.

We have, therefore, taken an early opportunity for making a thorough examination of the vehicles and for testing one of them, fully laden, on the Southend routes.

Three outstanding considerations have contributed to the choice of this type of vehicle. In the first place, for the reasons of maintenance and spare parts, a trolley-bus incorporating a standard motorbus chassis was desired ; the chassis, in this instance, is the well-known A.E.C. Regent. Mr. Fearnley also finds that the public is familiar with the appearance of a motorbus, and this he has aimed at simulating, departing so far as possible from all resemblance to a tramcar.

Secondly, several advantages commended the use of a single motor instead of the series-parallel doublemotor arrangement. The weight saving alone, allowing for the extra controls of the double motor, is about 5 cwt. Apart from this, it is possible to mount the single motor in approximately the position occu= pied by the engine of a motorbus and to employ motorbus transmission with offset propeller shaft and low floor level.

c26 The single motor is preferred also for its simplicity, lower capital cost and maintenance charge, whilst the saving of current claimed for the series-parallel control is not so big as to outweigh these advantages.

Thirdly, a four-wheeler of a length within 26 ft. is more suitable to certain of the narrow Southend routes than is the larger six-wheeler.

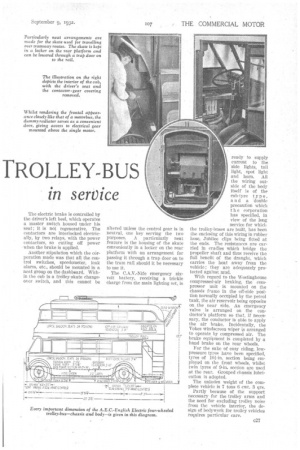

In our examination we turned first to the electrical equipment. The whole of the contactor gear is mounted on the chassis, the motor being mounted before it, so that, except for the lighting-wire connections, it would be possible to lift off the body without

serious wiring disturbance. The master contactors, which are housed centrally in the hill-width cab, are controlled by the driver's left foot, and the master key can be removed only when the control is in the neutral position. There are five resistance and one field-shunt notches.

Although this chassis is equipped with rheostatic braking, Mr. Fearnley has stipulated that this shall be reserved for emergency application, his argument being that compreSsedair braking is adequate for ordinary purposes and that the transmission stresses set up by regular electric braking are not warranted. The electric brake is controlled by the driver's left heel, which operates a master switch housed under his seat ; it is not regenerative. The contactors are interlocked electrically, by two relays, with the power contactors, so cutting off power when the brake is applied.

Another stipulation which the corporation made was that all the control switches, speedometer, leak alarm, etc., should be mounted in a neat group on the dashboard. Within the cab is a trolley-skate changeover switch, and this cannot be altered unless the control gear is in neutral, one key serving the two purposes. A particularly neat feature is the housing of the skate conveniently in a locker on the rear platform with an arrangement for passing it through a trap door on to the tram rail should it be necessary to use it..

The 0.A.V.-Nife emergency sixvolt battery, receiving a trickle .charge from the main lighting set, is ready to supply current to the Side lights, tail light, spot light and horn. All the wiring outside of the body itself is of the cab-tyre type, and a double precaution which t h e corporation has specified, in view of the long service for which the trolley-buses are built, has been the enclosing of this wiring in rubber hose, Jubilee clips being fitted at the ends. The resistances are carried in cradles which bridge the propeller shaft and thus receive the full benefit of the draught, which carries the heat away from the vehicle ; they are adequately protected against mud.

With regard to the Westinghouse compressed-air braking, the compressor unit is mounted on the chassis frame in the off-side position normally occupied by the petrol tank, the air reservoir being opposite on .the near side. An emergency valve is arranged on the conductor's platform so that, if necessary, the conductor is able to apply the air brake. Incidentally, the Vokes Windscreen wiper i,s arranged to operate by compressed air. The brake equipment is completed by a hand brake on the rear wheels.

For the sake of easy riding, lowpressure tyres have been specified, tyres of 101-in. section being employed on the front wheels, whilst twin tyres of 9-in. section are used at the rear. Grouped chassis lubrication is adopted.

The unladen weight of the complete vehicle is 7 tons 6 cwt. 3 qrs..

Partly because of the support necessary for the trolley arms and the need for excluding trolley noise from the vehicle interior, the design of bodywork for trolley vehicles requires particular care.

One of Mr. Fearnley's requirements was that the body frame should have its four corner pillars (up to the upper-saloon floor) made of teak, and that the entire fraine should be longitudinally trussed by means of diagonal steel tie rods with turnbuckle tensioners. Every frame joint is bracketed, and the oak floor bearers, which provide for a sunken central gangway, are flitched on both sides for their full length. The pillars and roofsticks are of English ash.

The upper saloon has an off-side sunken gangway, the seats being in alternate banks of three and four, and the stairway is in two straight flights with an intermediate landing. The construction permits of a gangway headroom of 5 ft. 10 ins. (lower saloon) and 5 ft. 8 ins. (upper saloon), whilst keeping the overall height to roof top to about 13 ft. 1 in.

On the near side at cant-rail level is a neat housing for the trolley pole. All the glass employed in the lower saloon is of the Triplex safety variety, this also being employed for the front upper-saloon windows.

• Ventilation has received special care. The lower saloon obtains a supply of fresh air by way of a duct under the driver's canopy, this having a hinged flap which passengers may control; extraction is by four Colt ventilators on the near side at cant-rail level, and G. D. Peters and Co., Ltd., of Slough, has supplied the drop windows for the lower deck. The upper saloon is similarly supplied with fresh air, extraction being effected by four Ashanco ventilators fitted on the roof quarters.

The trolley base bridges the roof, resting on four strengthened pillars, and the bridge portion is panelled so as to give it a smart appearance. On each side of the base is a wireless interference-prevention coil. Under each trolley mounting a large cork and rubber washer is fitted. The entire body rests upon the chassis on rubber pads which are placed beneath the floor bearers. Both exterior and interior panelling are executed in 18-gauge aluminium, plywood being avoided. A feature is that the lifeguard rails can be lifted out of spring-clip brackets.

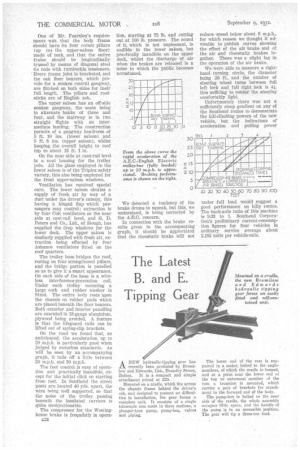

On the road we found that, as anticipated, the acceleration up to 20 m.p.h. is particularly good when judged by motorbus standards. As will be seen by an accompanying graph, it tails off a little between 20 m.p.h. and 30 m.p.h.

The foot control is easy of operation and practically inaudible, except for the initial click on starting from rest. In Southend the street posts are located 40 yds. apart, the wire being well supported, so that the noise of the trolley passing beneath the insulated carriers is quite unobjectionable.

The compressor for the Westinghouse brake is frequently in opera

tion, starting at 75 lb. and cutting out at 100 lb. pressure. The sound of it, which is not unpleasant, is audible in the lower saloon, but practically inaudible on the upper deck, whilst the discharge of air when the brakes are released is a noise to which the public becomes accustomed.

We detected a tendency of the brake drums to squeak, but this, we understand, is being corrected by the A.E.C. concern.

In connection with the brake results given in the accompanying graph, it should be appreciated that the rheostatic brake will not reduce' speed below about 6 m.p.h., for which reason we thought it advisable to publish curves showing the effect of the air brake and of the air and rheostatic brakes together. There was a slight lag in the operation of the air brake.

We were able to measure a righthand turning circle, the diameter being 56 ft., and the number of steering wheel turns between full left lock and full right lock is 4.1, this sufficing to render the steering comfortably light.

Unfortunately there was not a sufficiently steep gradient on any of the Southend routes to demonstrate the hill-climbing powers of the new vehicle, but the indications of acceleration and pulling power under fun load would suggest a good performance on hilly routes. The back-axle ratio of this machine is 9.33 to 1. Southend Corporation's preliminary current-consumption figures for four vehicles in ordinary service average about 2.182 units per vehicle-mile.