An Austin Anti-knock Cylinder Head

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

nETONATION is generally admitted to be clue to the advancing -flame front causing the " tail end" of the

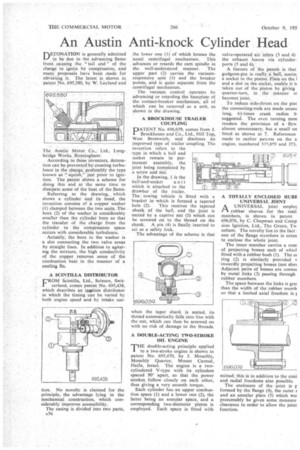

• charge to ignite by compression, and many proposals have been made for • 'obviating it. The latest is shown in patent No. 695,580, by W. Layland and The Austin Motor Co.,. Ltd., Longbridge Works, _Birrriingha,m': According to these inventors, detonation can be prevented by creating turbulence in the charge, preferably the type known as squish," just prior to ignition, The patent shows a scheme for doing this and at the same time to dissipate some of the heat of the flame.

Referring to the drawing, which shows a cylinder and its head, the invention consists of a copper washer (I) clamped between the two units. The bore (2) of the washer is considerably smaller than the cylinder bore so that the transfer of the charge from the cylinder to the compression space occurs with considerable turbulence. • Actually, the bore, in the washer is a slot connecting the two valve areas by straight lines. In addition to agitating the mixture, the high conductivity of the copper removes some of the combustion heat in the manner of a Cooling fin.

A SCINTILLA DISTRIBUTOR rROM Scintilla, Ltd., Soleure, Swit• zerland, comes patent No. 695,438, which describes an igaition distributor in which the timing can be varied by both engine speed and by intake sue

tion. No novelty is claimed for the principle, the advantage lying in the mechanical construction, which considerably improves accessibility.

The casing is divided into two parts, is36 the lower one (1) of which houses the usual centrifugal mechanism. This advances or retards the cam spindle in the well-understood manner. The upper part (2) carries the vacuumresponsive unit (3) and the breaker points, and is quite separate from the centrifugal mechanism.

The vacuum control operates by advancing or retarding the baseplate of the contact-breaker mechanism, all of which can be removed as a unit, as shown in the drawing,' A BROCKHOUSE TRAILER COUPLING

DATENT No. 696,039, comes from J.

Brockhouse and Co., Ltd., Hill Top, West Bromwich, and discloses an improved type of trailer coupling. The invention refers to the type in which a ball and socket remain in permanent assembly, the joint being completed by a screw and tint.

In the drawing, 1 is the ball-and-socket unit which is attached to the drawbar of the trailer. The.towing vehicle is fitted with a bracket in -which is formed a tapered hole (2). This receives the tapered shank of the ball, and the joint is united by a captive nut (3) which can be screwed on to the thread on the shank. A pin (4) is finally inserted to act as a safety lock.

The advantage of the scheme is that when the taper shank is seated, its thread automatically falls into line with the nut, which can then be screwed on with no risk of damage to the threads.

A DOUBLE-ACTING TWO-STROKE OIL ENGINE

THE double-acting principle applied to a two-stroke engine is shown in patent No. 695,470, by J. Mouchly, Mouchly Quarter, Mount Carmel, Haifa, Israel. The engine is a twocylindered V-type with its cylinders spaced 90' apart, so that the power strokes follow closely on each other, thus giving a very smooth torque.

Each cylinder has an upper combustion space (1) and a lower one (2), the latter being an annular space, and a corresponding two-diameter piston is employed. Each space is fitted with

valve-operated air inlets (3 and 4) the exhaust leaves via cylinderports (5 and 6).

A feature of the patent is that gudgeon-pin is really a ball, seatin: a socket in the piston. Flats on the 1 and a slot in the socket, enable it tc taken out of the piston by giving quarter-turn, in the manner ol bayonet joint.

To reduce side-thrust on the pist the connecting-rods are made unusu long, 6i-times crank radius b. suggested. The even turning mon renders the provision of a flyw. almost unnecessary, but a small on fitted as shown at 7. References made to earlier patents on the s: engine, numbered 335,859 and 373, A TOTALLY ENCLOSED RUN UNIVERSAL JOINT

rAA UNIVERSAL joint emplo3 rubber sleeves for the resit members, is shown in patent 696,076, by C. Chapman and Comp sion Ignition, Ltd., The Green, Tw enham. The novelty lies in the fact, one of the flange members is exten to enclose the whole joint.

The inner member carries a num of projecting bosses each of whict fitted with a rubber bush (1). The oi ring (2) is similarly provided v . inwardly projecting bosses (not slim Adjacent pairs of bosses are connet by metal links (3) passing through rubber members.

The space between the links is grei than the width of the rubber memb so that a limited axial freedom is-1 mitted; this is in addition to the coni and radial freedoms also possible.

The enclosure of the joint is p formed by the flange (4), the outer and an annular plate (5) which wo: presumably be given some measure clearance in order to allow the joint function.