Ball-bearing Repair Proves Economic

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

CONSIDERABLE doubt exists in the commercialmotor industry as to the practicability of repairing worn bail and roller bearings. We have satisfied ourselves, however, that such bearings reconditioned by the processes practised by Scraggs, Whatley and Co., Ltd., 'a, Harcourt Street, Paddington, London, W.l, are satisfactory in respect of efficient running and durability.

The concern has long experience in this specialist work, its factory is equipped with precision machines for the operations involved, and its stall includes operatives highly skilled in performing them.

The whole question turns upon the fact that the outer and inner members of first-class ball and roller bearings are hardened all through, not case-hardened, as is sometimes believed to be the case. Accordingly, the life of the members is in no way affected by regrinding the damaged bail or roller tracks. Moreover, no anxiety need be felt in the matter of fatigue. .

It is not unusual for a bearing running under good con

ditions to last 10 y-ears. Then it has probably been

renewed only because of wear. If that hearing had become worn out in five years, it would, therefore, have at least another five years' life, in so far as the nature of the metal was concerned. Bearings would possibly last indefinitely if wear did not take place.

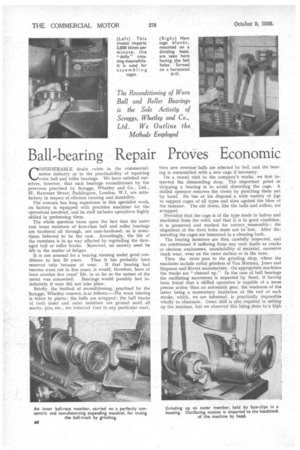

Briefly, the method of reconditioning, practised by the Scraggs, Whatley concern, is as follows :—The worn bearing is taken to pieces; the balls are scrapped ; the ball tracks of both inner and outer members are ground until all marks, pits, etc., are removed (not to any particular size), then new oversize balls are selected by feel, and the bearing is reassembled with a new cage if necessary.

• On a recent visit to the company's works, we first inspected the dismantling shop. The important point in stripping a bearing is to avoid distorting the cage. A skilled operator removes the rivets by punching them out by hand. He has at his disposal a wide variety of jigs to support cages of all types and sizes against the blow of the hammer. The old rivets, like the balls and rollers, are scrapped.

Provided that the cage is of the type made in halves and machined from the solid, and that it is in good condition, it is preserved and marked for correct ,reassembly ; the alignment of. the rivet holes must not be lost, After dismantling the cages are immersed in a cleaning bath.

The bearing members are then carefully inspected, and are condemned if suffering from any such faults as cracks or obvious weaknesses, unsuitability of material, excessive track wear, wear on the outer surface or in the bore.

Then the races pass to the grinding shop, where the machines include radial grinders of Van Norman, Jones and Shipman and Rivett manufacture.. On appropriate machines the tracks are " cleaned up." In the case of ball bearings the oscillating movement is imparted by hand, it having been found that a skilled operative is capable of a mom precise action than an automatic gear, the weakness of tho latter being a momentary hesitation at the end of each stroke, which, we are informed, is practically impossible wholly to eliminate. Great skill is also required in setting up the machine, but we observed this being done to a high

degree of accuracy, whilst the finished track surface approaches very near to perfection. Noattempt is made to work to dimensions, the grinding being continued, as mentioned before, merely until irregularities are removed. In mounting the ball-race member on the headstock of the grinder, absolute concentricity is essential. Furthermore, it must not be gripped in chuck jaws, or it will be slightly deformed, and the track will not be circular.

In the case of outer members the housing is provided with a number of radial setscrews. These are set to the diameter of the race, and, after setting, their points are trued by the grinding wheel (thus ensuring perfect concentricity) until the race is a fit within them. It is held by face-grips.

For inner members, an eXpanding mandrel is commonly used, this, of course, being truable in similar manner. Here, :dso, the face is used for gripping the work. Where thrust bearings are concerned, the radial thickness of the race is sufficient to give it sufficient rigidity to prevent distortion.

It is worthy of mentiOn that the bulk of the equipment used in conjunction with these machine tools, etc., is made by the Scraggs. Whatley concern; and the maintenance of the machines, upon which the accuracy of the parts produced depends, is of the highest order. Steel balls exceeding standard sizes by mere than 0.010 in. are not obtainable.' For this reason alone, therefore, it is impracticable to remove more than a few ethousandths in truing ball tracks. In actual fact, the 0.005-in.oversize ball is the size most commonly used.

When the races have been ground they go to the assembly shop. Here they are paired and assembled with balls of the correct oversize, by experiment.

The sensitivity of the finger-tips of the manipulator has been proved infallible as a test of accuracy of grinding and ball selection, A range of 32 sizes of rivet is available for assembling cages. A Grant riveter is used for expanding the ends of the rivets, which are inserted by hand. Features of this tool are its speed-3,000 blows per minute—the use of a hickory rocking beam to transmit the impulses in conjunction with a rubber-cushion return, and the shape of the " dolly," the piece which actually forms the rivet head. This last-named is not cupped but of channel formation, and is rotated mechanically while operating. Thus, at each blow, the metal can, " flow.' along the channel, with the result that a well-shaped head is formed and the two halfcages are tightly held together.